12 – ENGLISH

EN

4.8 LEARNING OF THE MECHANICAL STOP

POSITIONS

Once the connected devices have been learned, the mechan-

ical stop positions must be learned (maximum opening and

maximum closing). This procedure can be carried out in three

different ways: automatic, manual and mixed.

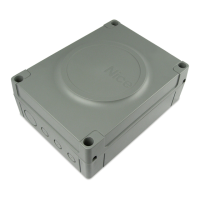

In automatic mode, the control unit learns the mechanical stops,

calculates the most appropriate gate leaf offsets and calculates

the slowdown points “A” (“Figure 15“).

a

Before starting the self-learning procedure in auto-

matic mode, verify that the motor force is suited to

the type of motor being used (see paragraph “Level

2 programming (adjustable parameters) - Function

L6“).

In manual mode, the positions (“Figure 15”) are programmed

one-by-one, by moving the leaves to the desired points. The po-

sition to be programmed can be identied when one of the eight

LEDs “L1...L8” ashes (see “Table 4“).

In the mixed mode, it is possible to run the automatic procedure

then, using the manual procedure, modify one or more positions.

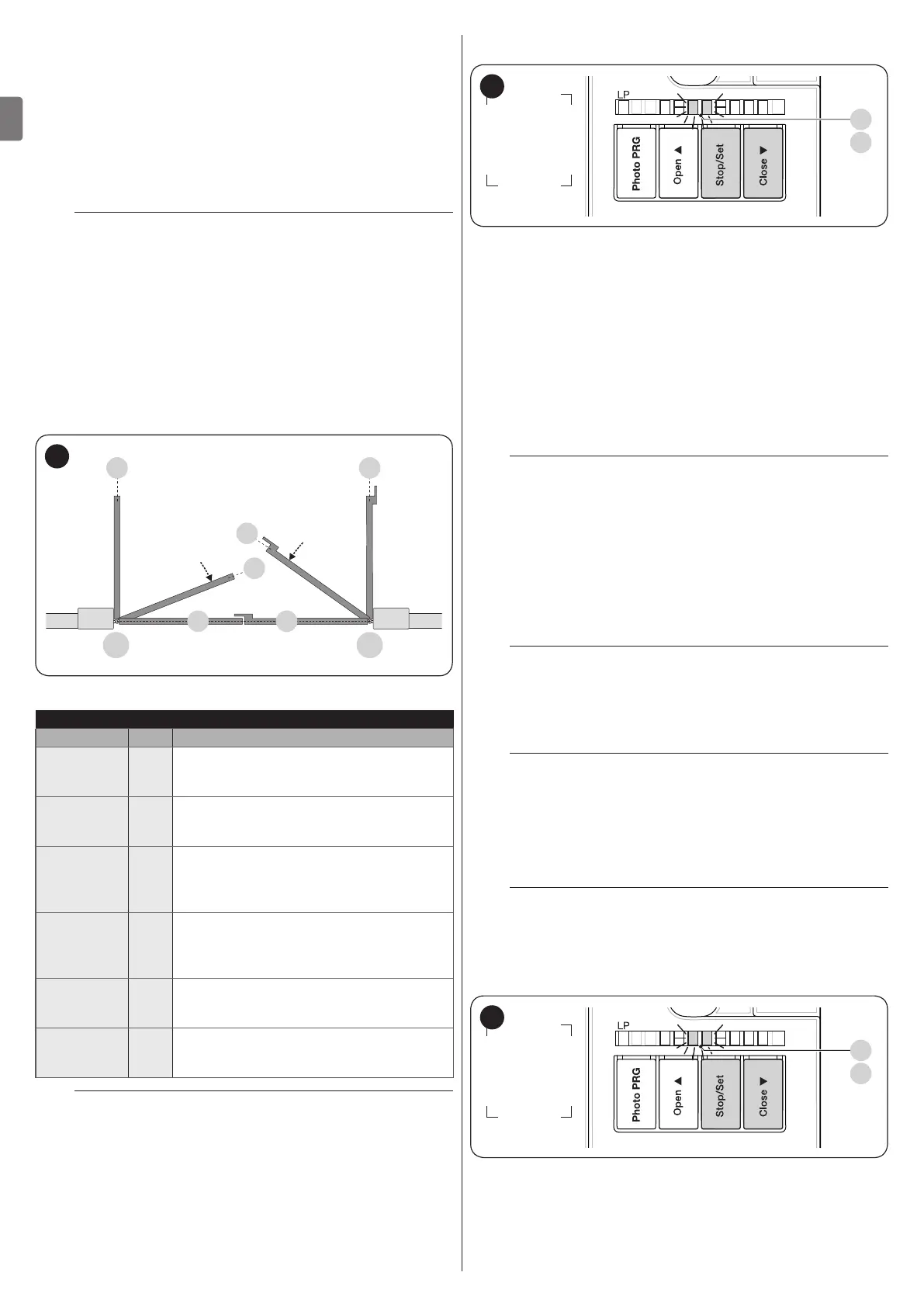

1 1

M1 M2

0 0

A

A

15

Table 4

PROGRAMMING POSITIONS

Position LED Description

Position 0

(motor 1)

L1

maximum closing position: when the leaf

relative to motor 1 strikes the closing

mechanical stop

Position 0

(motor 2)

L2

maximum closing position: when the leaf

relative to motor 2 strikes the closing

mechanical stop

Position A

(motor 2)

Slowdown

start

L5

Position after which the motor 2 closing

speed will start decreasing until the leaf

stops in position 0

Position A

(motor 1)

Slowdown

start

L6

Position after which the motor 1 closing

speed will start decreasing until the leaf

stops in position 0

Position 1

(motor 2)

L7

Maximum opening position: when the leaf

relative to motor 2 strikes the opening

mechanical stop

Position 1

(motor 1)

L8

Maximum opening position: when the leaf

relative to motor 1 strikes the opening

mechanical stop

m

The “slowdown” conguration (LEDs “L5” and

“L6”) can be done “manually” after conguring the

closing and opening positions.

4.8.1 Learning in automatic mode

L5 L6 L7 L8L4L3L2L1

L3

L4

16

To effect the automatic learning procedure:

1. simultaneously press and hold the and

g

buttons

h

2. release the buttons when LEDs “L3” and “L4” start ash-

ing quickly (after roughly 3 seconds)

3. check that the automation carries out the following ma-

noeuvre sequences:

a. closing of motor M1 up to the mechanical stop

b. closing of motor M2 up to the mechanical stop

c. opening of motor M2 up to the mechanical stop

d. opening of motor M1 up to the mechanical stop

e. closing of motor M1 up to the mechanical stop

f. closing of motor M2 up to the mechanical stop.

m

If the rst two manoeuvres (a and b) are not “clos-

ing” but “opening” manoeuvres, press the

f

or

h

button to stop the learning phase. At

this point, invert the control wires (external posi-

tions with respect to the terminal) on the motor that

executed the opening manoeuvre and repeat the

self-learning procedure.

4. at the end of the closing manoeuvre (e-f) of the two mo-

tors, LEDs “L3” and “L4” switch off to indicate that the

procedure was carried out correctly.

m

If, during the automatic learning procedure, the

photocells or one of the devices connected to the

“stop” input intervene, the procedure interrupts and

LED L1 starts ashing. In this case, the self-learning

procedure must be repeated from the beginning.

l

The automatic learning procedure can be run again

at any time, even after the installation phase; for ex-

ample, after modifying the position of the mechan-

ical stops.

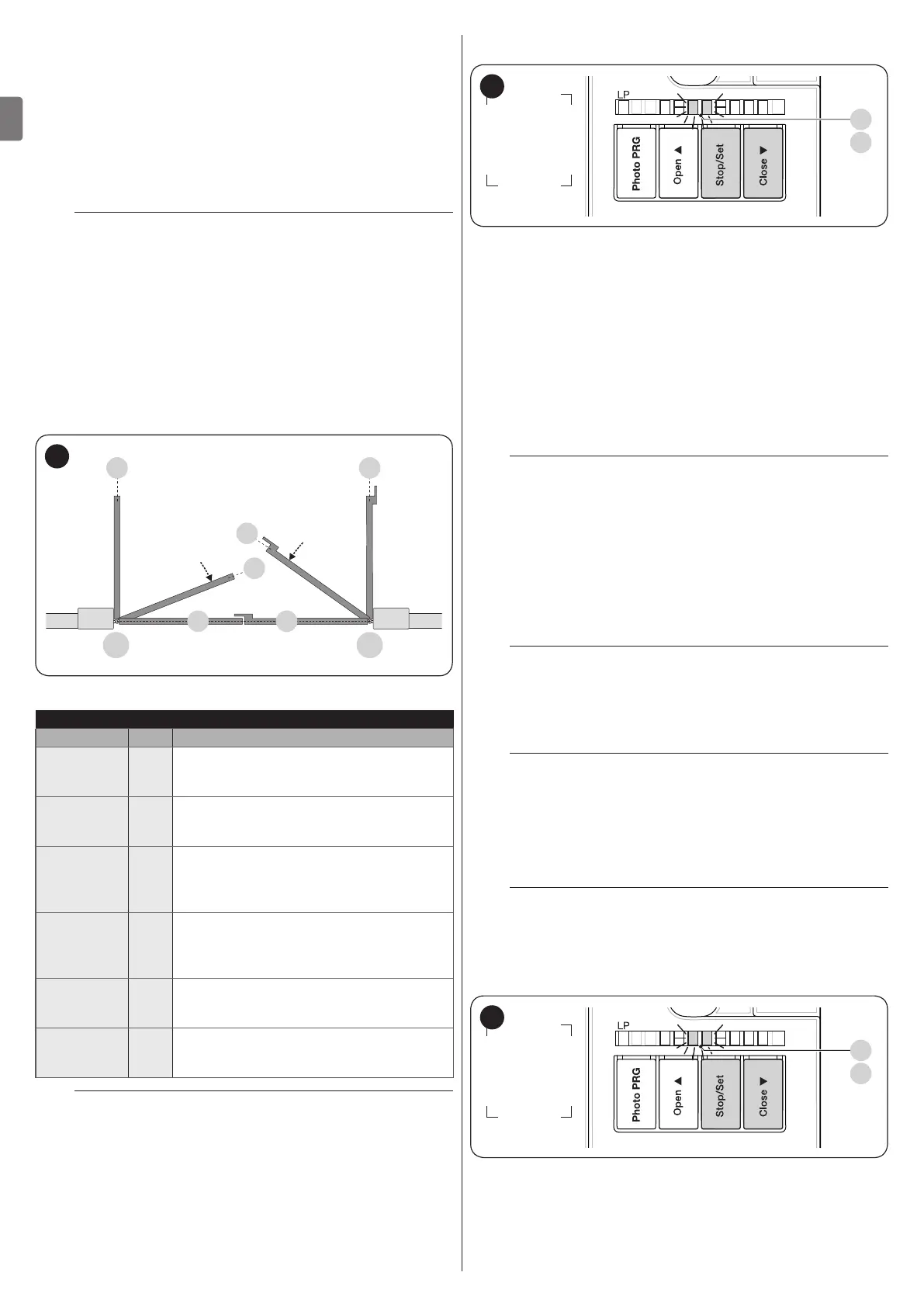

4.8.2 Learning in manual mode

m

The user has maximum 10 seconds to press the

buttons consecutively during the learning proce-

dure. After this time, the procedure terminates au-

tomatically and memorises the changes made up to

that time.

L5 L6 L7 L8L4L3L2L1

L3

L4

17

To effect the manual learning procedure:

1. simultaneously press and hold the and

g

buttons

h

Loading...

Loading...