85Service Manual – SC6000 30 - Solution System

Dust Guard Option

The Dust Guard option is available only on cylindrical machines with side sweep. A water mist is sprayed in

front of the side broom, and controlled by a solenoid just above the broom. The option pump at the rear of the

machine pressurizes the water. The wash hose option cannot be added to a machine that has Dust Guard.

EcoFlex Option

Machines that have the EcoFlex option have on-board detergent mixing using a pump-driven detergent

injection system. The detergent is stored in the removable detergent tank below the operator’s seat, which

has a suction hose from the detergent pumps. The detergent pumps draw the liquid from the detergent tank

and inject it into the solution line before the solution solenoid. The ow rate of the detergent is controlled by

the Main Machine Controller using PWM.

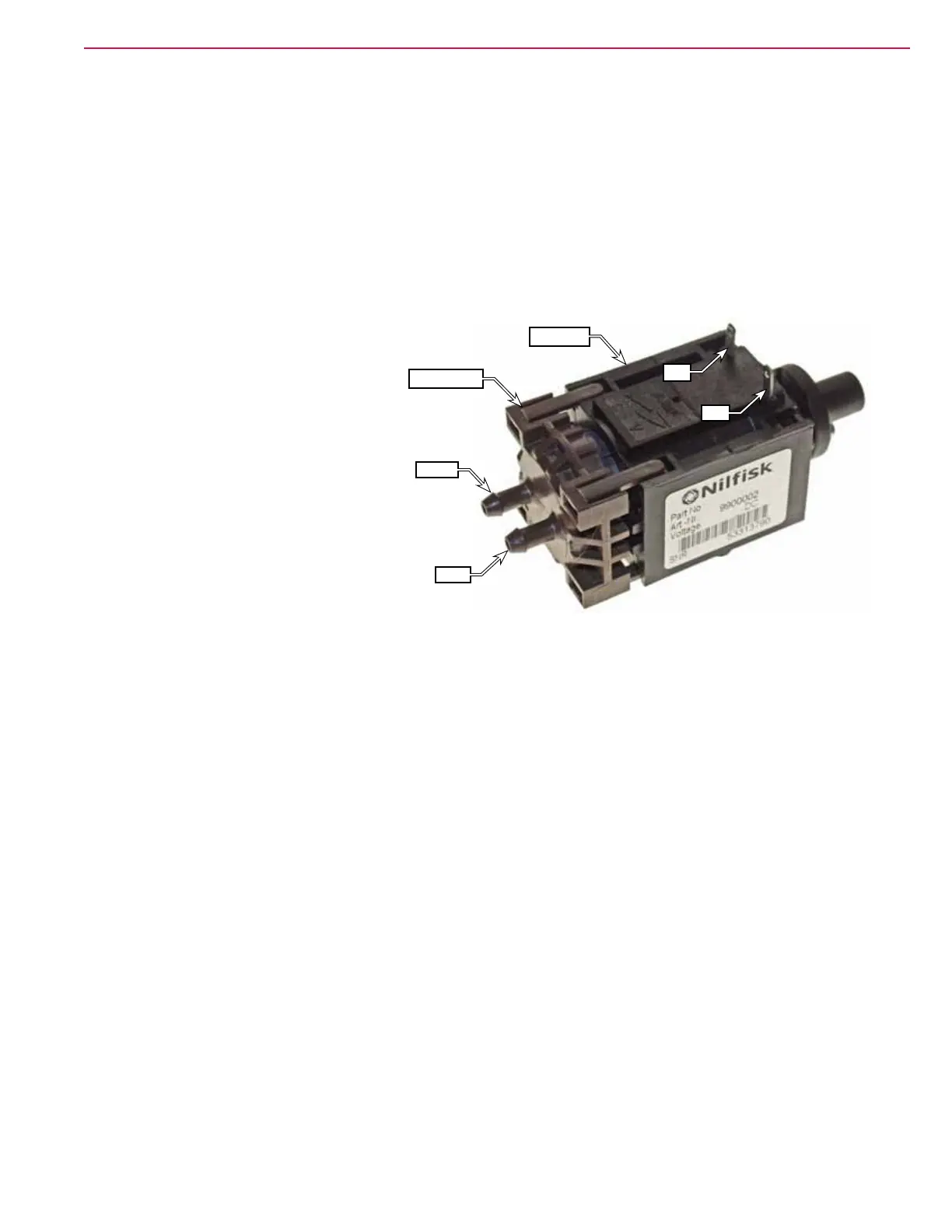

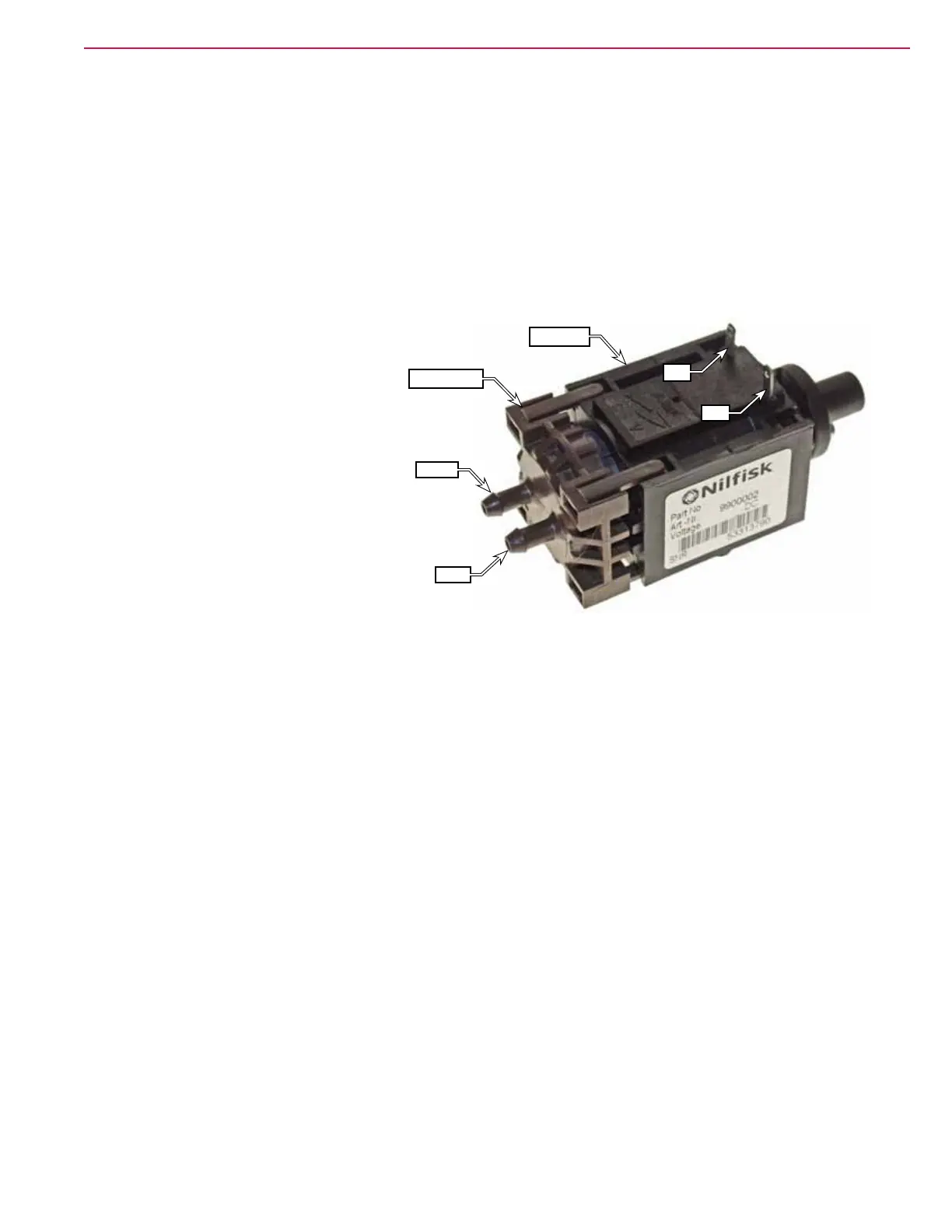

There are two detergent pumps that operate

in parallel to deliver detergent to the scrub

deck. Each pump uses a solenoid-driven

diaphragm with one-way check valves. As

the solenoid oscillates in and out, it drives

a exible diaphragm that draws uid in

during the retraction stroke, and drives

uid out during the compression stroke. The

check valves allow uid to enter only though

the inlet port, and exit only through the

outlet port.

Unlike an AC solenoid that moves its

plunger the same direction regardless

of the electrical polarity, a DC solenoid

changes its direction of travel depending

on the electrical polarity of the coil. Even though the EcoFlex pumps use DC solenoids, they still contain a

mechanical return spring to return the plunger to its relaxed state when no power is present.

In many other machines, the solenoid is actively driven in only one direction (usually intake), but passively

returned via the return spring (usually exhaust). For higher ow rates, the SC6000 machine uses AC-

Driven, Active-Return solenoid pumps. So even though the return spring already wants to “Passively” drive

the plunger outward, the Main Machine Controller “Actively” pushes the plunger back out. So in effect, the

pumps are DC solenoids driven by an AC square-wave signal.

In the forward-bias direction, with positive-to-positive and negative-to-negative, as shown above; the

solenoid plunger retracts away from the diaphragm. This results in a suction at the inlet port, and uid is

drawn into the cavity caused by the diaphragm.

If voltage is simply removed at this point, the return spring will passively push the plunger forward, and

the spring pressure will push the uid out of the outlet port. However, if the solenoid is reverse-biased with

positive-to-negative and negative-to-positive, the plunger is actively pushed forward with a greater force

than what the spring alone can impart. Because this is the compression stroke of the diaphragm, the pump

can pump faster/harder against any resistance of the outlet tubing. This active-return also permits the pump

to operate at a higher PWM frequency for higher ow rates.

One thing to note about troubleshooting any solenoid driven pump, is that if the solenoid is already in its

relaxed (compression) stroke, energizing the coil in the reverse-bias direction will not give any outward

appearance that the solenoid was activated, because it is already driven in that same direction. So if

manually powering the coil, make sure to check both polarities before concluding whether the solenoid has

failed or not.

Outlet

Inlet

Pos

Neg

Diaphragm

Solenoid

Loading...

Loading...