33

ROTARY JOINT MAINTENANCE

REPLACEMENT OF THE SEALS IN THE ROTARY JOINT

Step 3

Inspection:

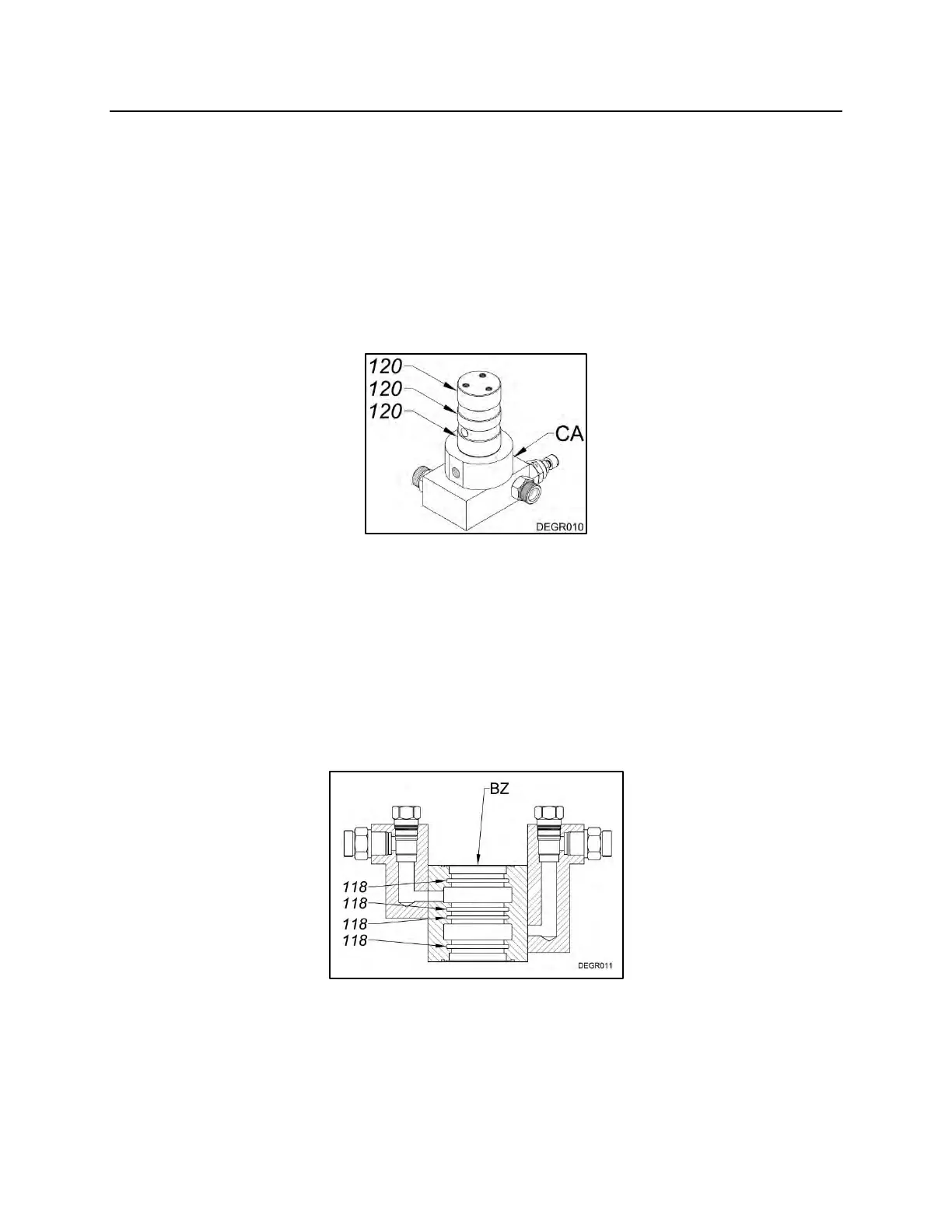

Visually inspect the sealing surfaces of the spindle (CA) for damage, which may hamper

the ability of the main seals to seal. Polishing the surfaces (120) may clean up light

scratching. Heavy scratching or galling may indicate rotator bearing play.

Figure 3

Step 4

Seal removal and replacement:

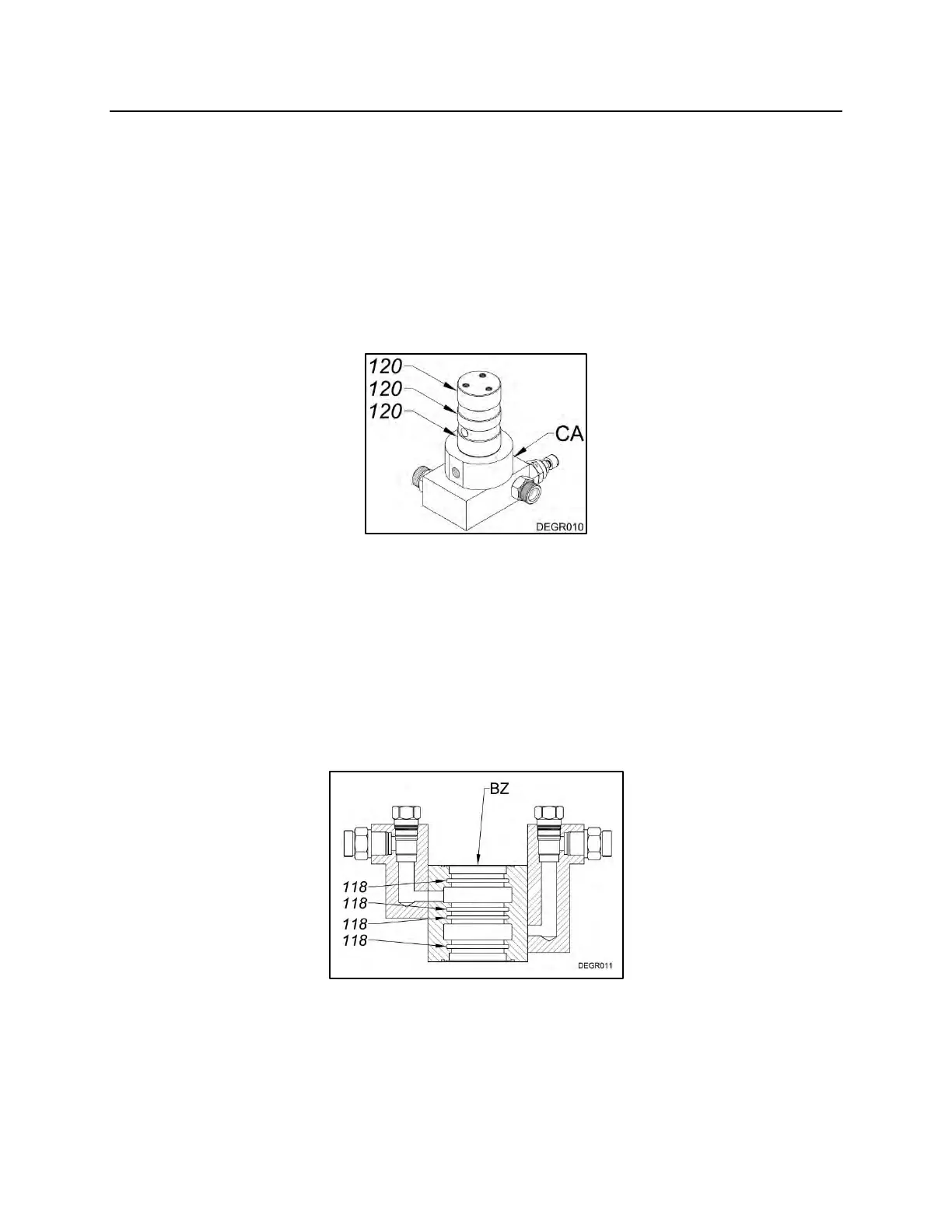

Sealing is accomplished by the use of main seals, which ride against the “Spindle” and

glide bearings. Remove the main seals and glide rings with a seal pick (note the proper

placement of main seals and glide bearings). Check the grooves (118) in the “Spindle

Case” (BZ) for burrs or scoring damage. Light grinding or polishing may be required.

Figure 4

Loading...

Loading...