30

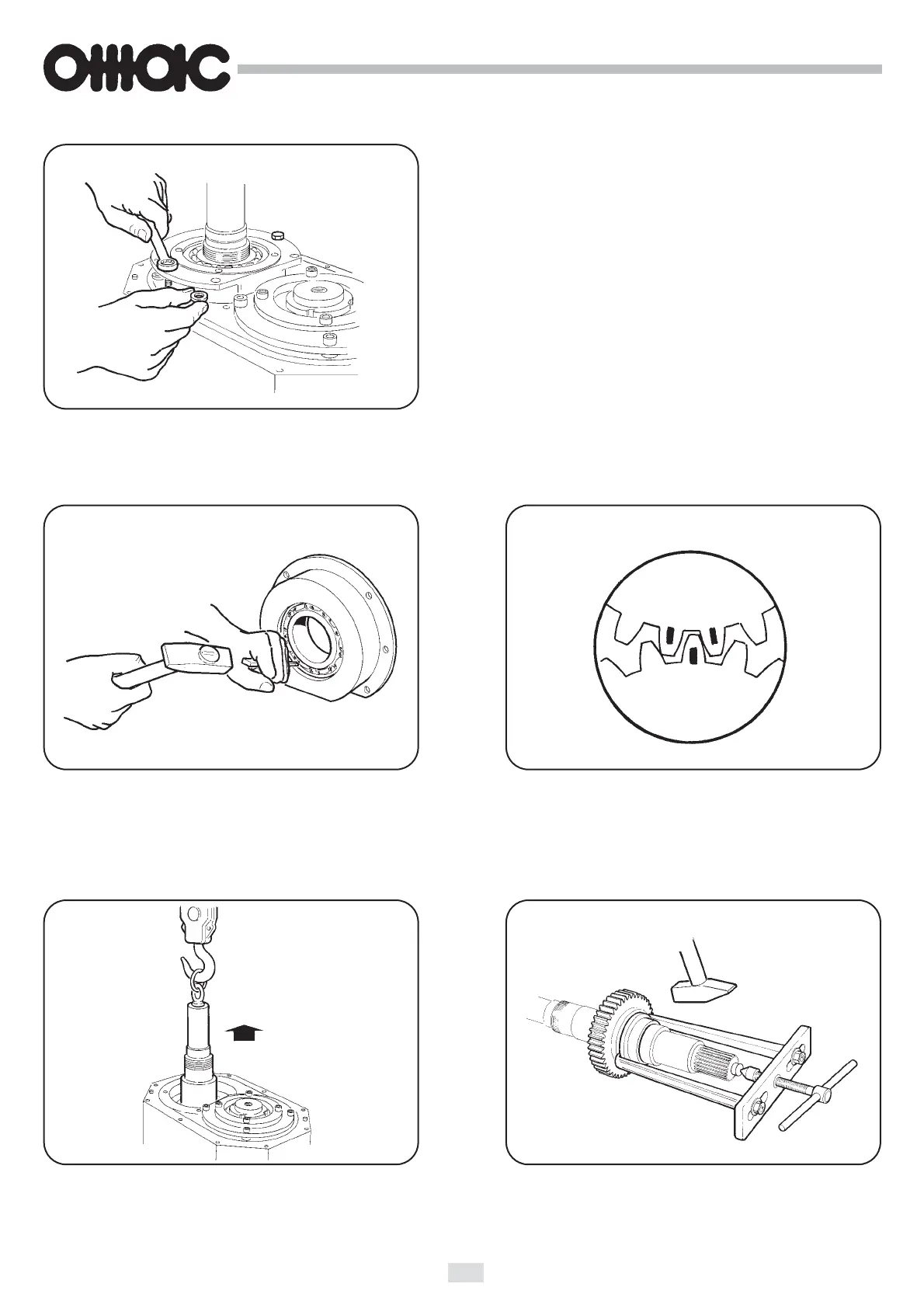

19. Stand the pump upright and extract the two bearing

supports, making use of the threaded holes for

removal. ▲ Doing so you will remove the spacers

for axial adjustement too, which should be marked

and separated for a right re-setting while assembling.

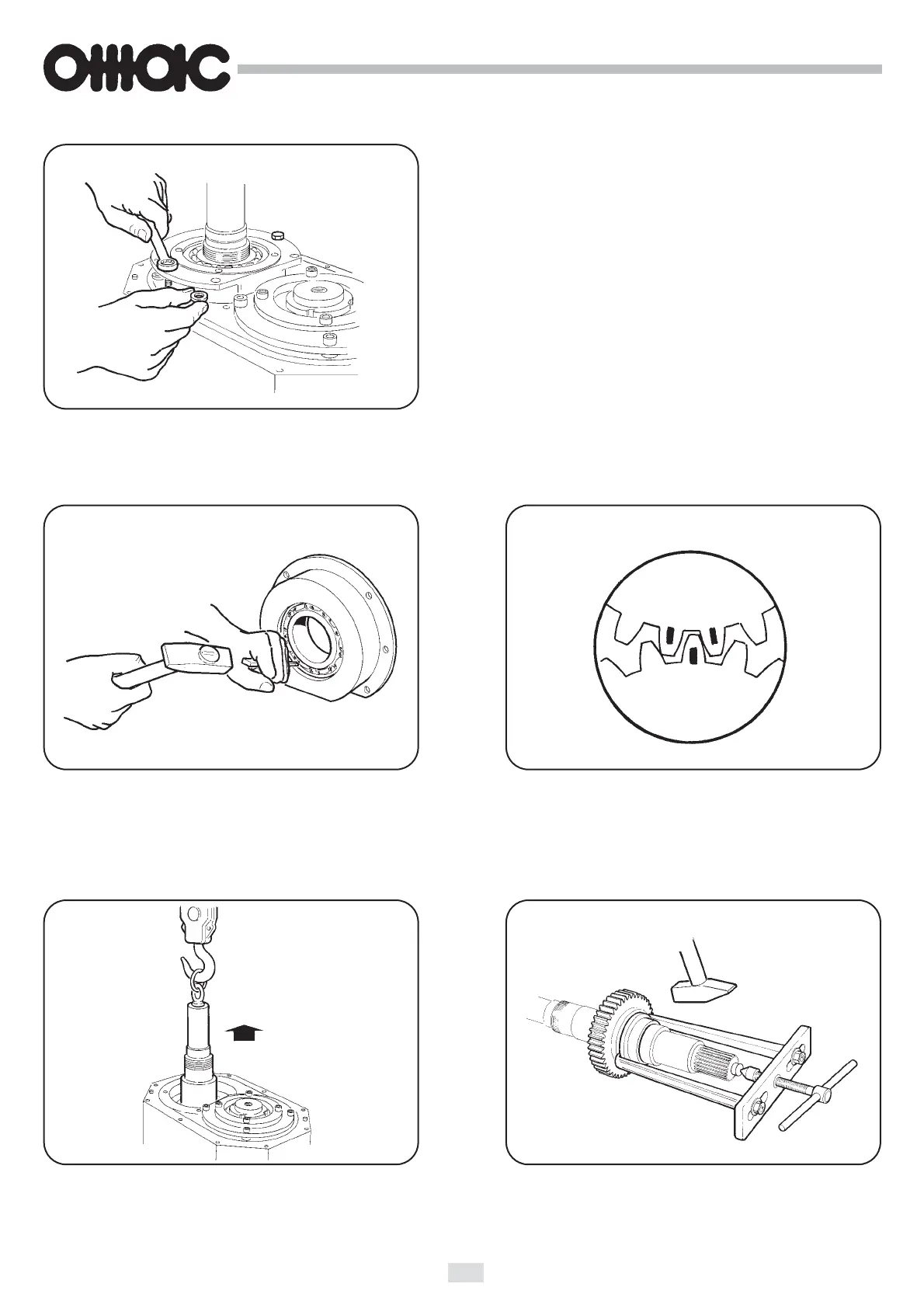

20. Remove the ball bearing from its support, taking

away the bull ring.

21. Mark the gears in order to set them rightly while re-

assembling.

22. Withdraw the shafts, with the gears, still inserted.

For this operation we suggest a mechanical lifting

equipment, which can use the threaded holes

arranged on shaft ends.

23. Remove the inside ring of the roller bearing by means

of an extractor. Remove the gear taking care not to

damage the toothing outline.

Loading...

Loading...