4 -The pump should be installed near the source, from which it sucks.

5 -Reduce at min. bends and necks along the whole line.

6 -Use large radius bends, avoiding Tees and needless runs.

7 -Check the perfect inlet connection seal not to reduce the pump suction power.

8 - The piping weight must not load on pump body and the

connection must be carried out without forcing in order to

avoid overloads and distortion of the rotor case.

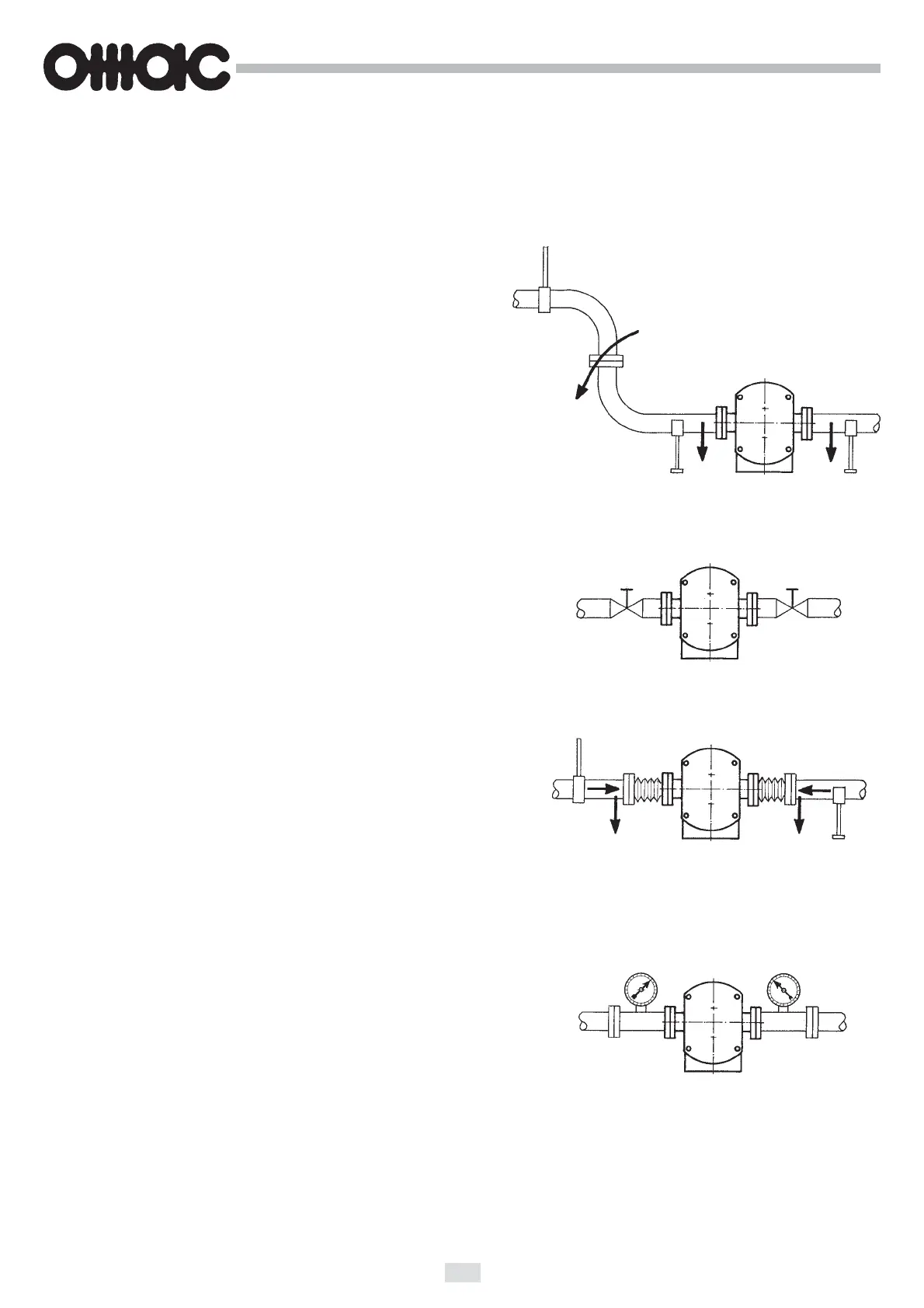

9 - Especially in case of very long piping system isolation

valves on both inlet and outlet side to permit pump

maintenance and removal without total draining of the piping

system.

10 - Where possible arrange a flexible expansion joint to

reduce vibration and to avoid forcing, due to thermal

expansion of piping.

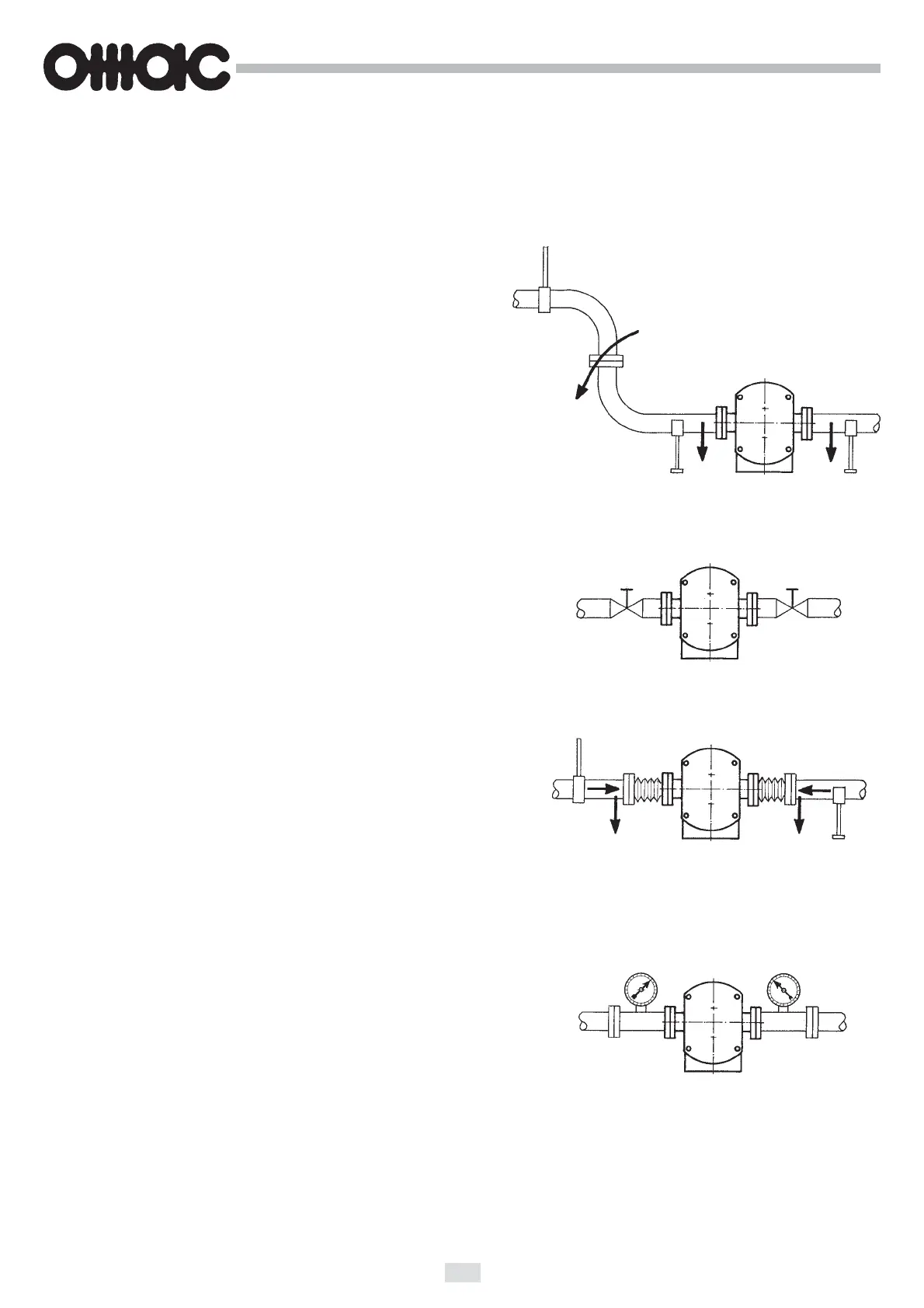

11 - We advise to arrange gauges and vacuum gauges near

the pump. They are usefull to check the pump working

conditions and diagnose possible trouble such as:

– pressure overload

– flow absence

– instability in duty conditions

– cavitation

12 - Where necessary arrange on inlet a filter, whose suction area must not be smaller than 4-5 time the suction pipe

to minimize the friction losses.

13 - During the pump unit installation it's necessary to leave a usefull room for maintenance and possible removal.

14 - If the pump is not flooded, arrange on inlet side a "foot" valve or a check valve to keep the priming.

6

Fig. 5

Fig. 4

Fig. 3

Fig. 2

Loading...

Loading...