OPTIMUM

MASCHINEN - GERMANY

Assembly

30 / 11 / 2007 Page 15Assembly Add-on kit D240/D280 ; Version 1.3.3

© 2007

GB

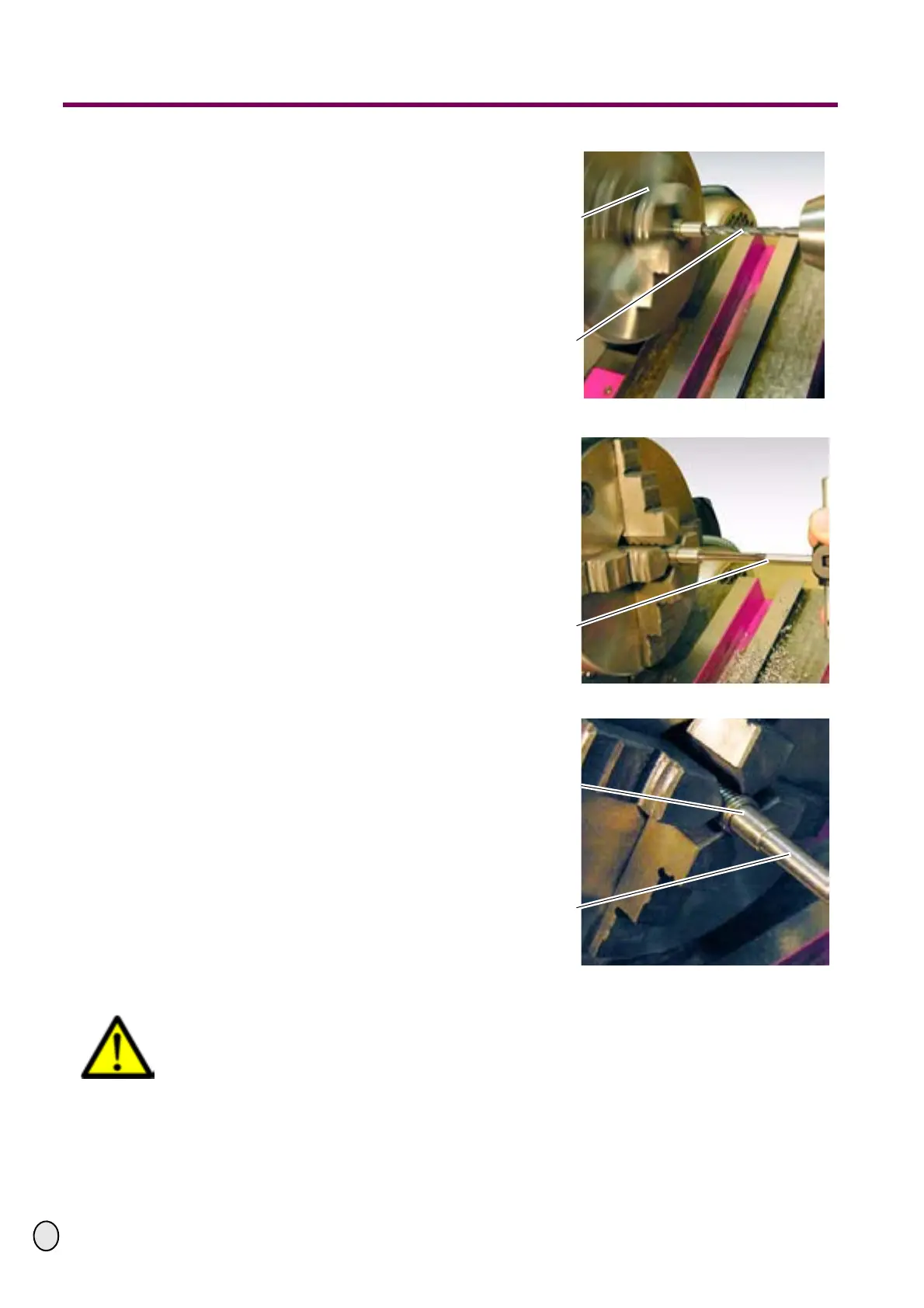

£ Drill about 15 mm deep into the

spindle with a 5.8 mm drill.

£ Deburr the hole with countersink.

£ Remove the dirt from the hole with

compressed air.

Illustr.: 4-18: Hole in the spindle

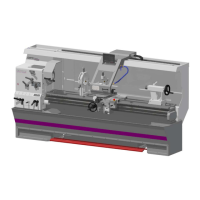

£ Ream the hole in the spindle with a

reamer 6 H7. Use oil as lubricant.

£ When reaming, make sure that the

reamer is being held at right angles.

£ Remove the chips from the reamed

hole with compressed air.

Illustr.: 4-19: Reaming of 6H7

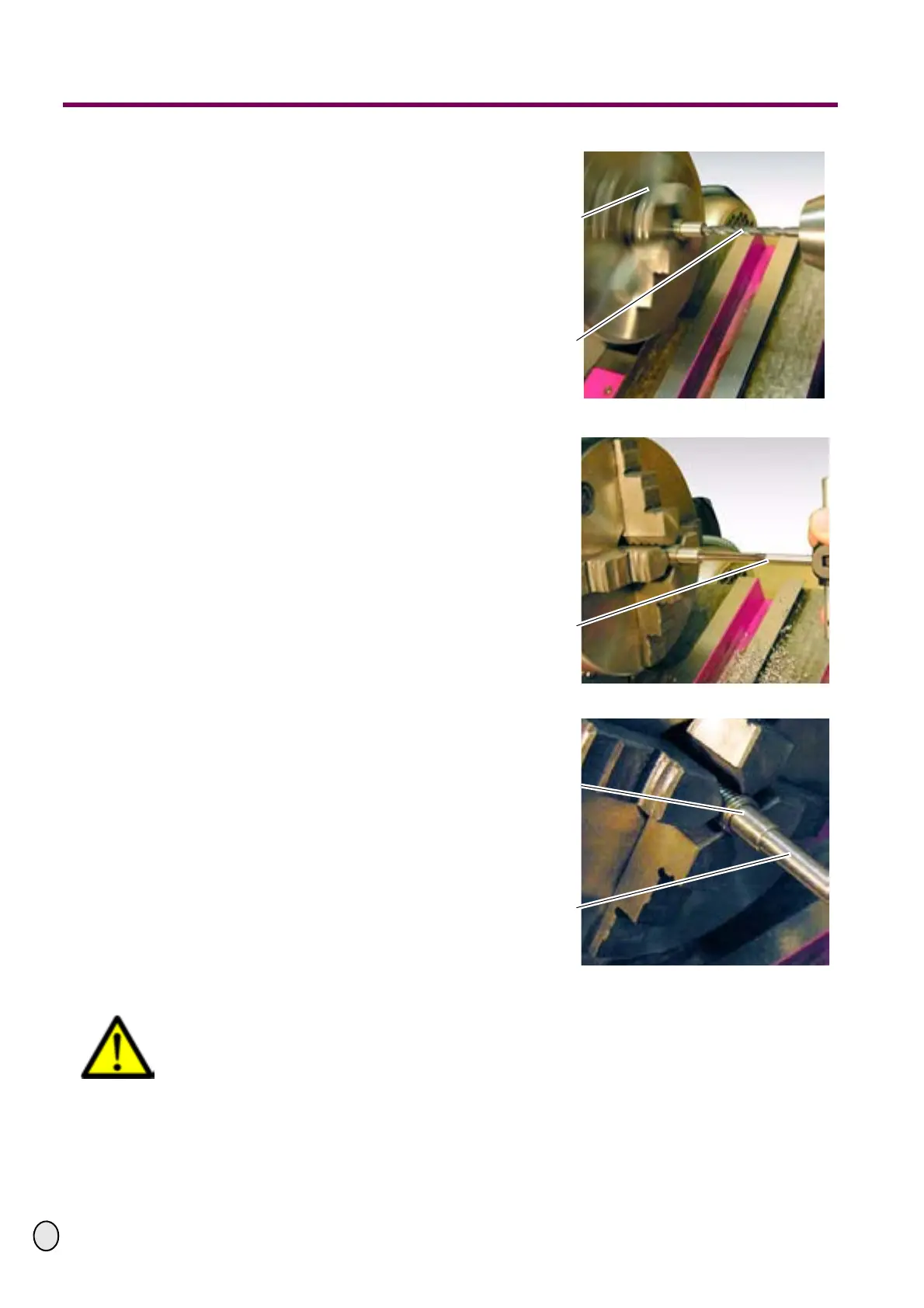

£ Check if the longer relief of the shaft

elongation (part 11) fits into the

reamed hole 6 H7.

Illustr.: 4-20: Check shaft relief

CAUTION!

Disconnect the machine in order that there is zero potential.

Lathe chuck

Drill 5,8 mm

Reamer 6 H7

Spindle X axis

Shaft elongation

Loading...

Loading...