Operation

Version 1.0.2 - 2020-07-0726 Translation of original instructions

DP26

EN

DP26_GB.fm

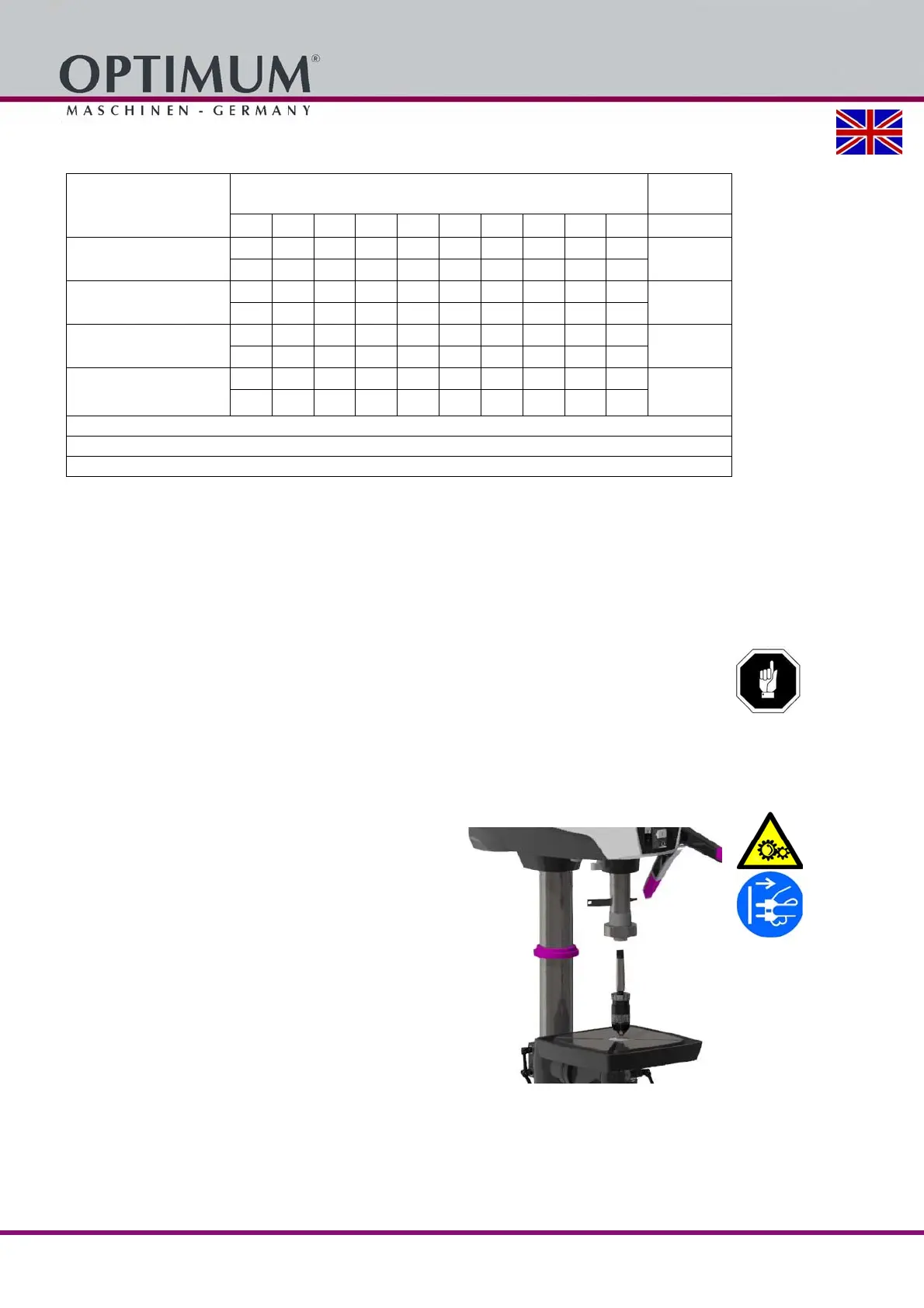

4.10 Standard values for speeds with HSS – Eco – twist drills

The above data are standard values. In some cases it may be advantageous to increase or

decrease these values.

A cooling or lubricating agent should be used when drilling.

For stainless materials (e.g. VA – or NIRO steel sheets) do not centre, as this will result in

the material compacting and the drill bit rapidly becoming blunt.

The workpieces need to be tensed inflexibly and stably (vice, screw clamp).

4.11 Drill chuck

ATTENTION!

Make sure that the clamped tool is firmly and correctly fitted.

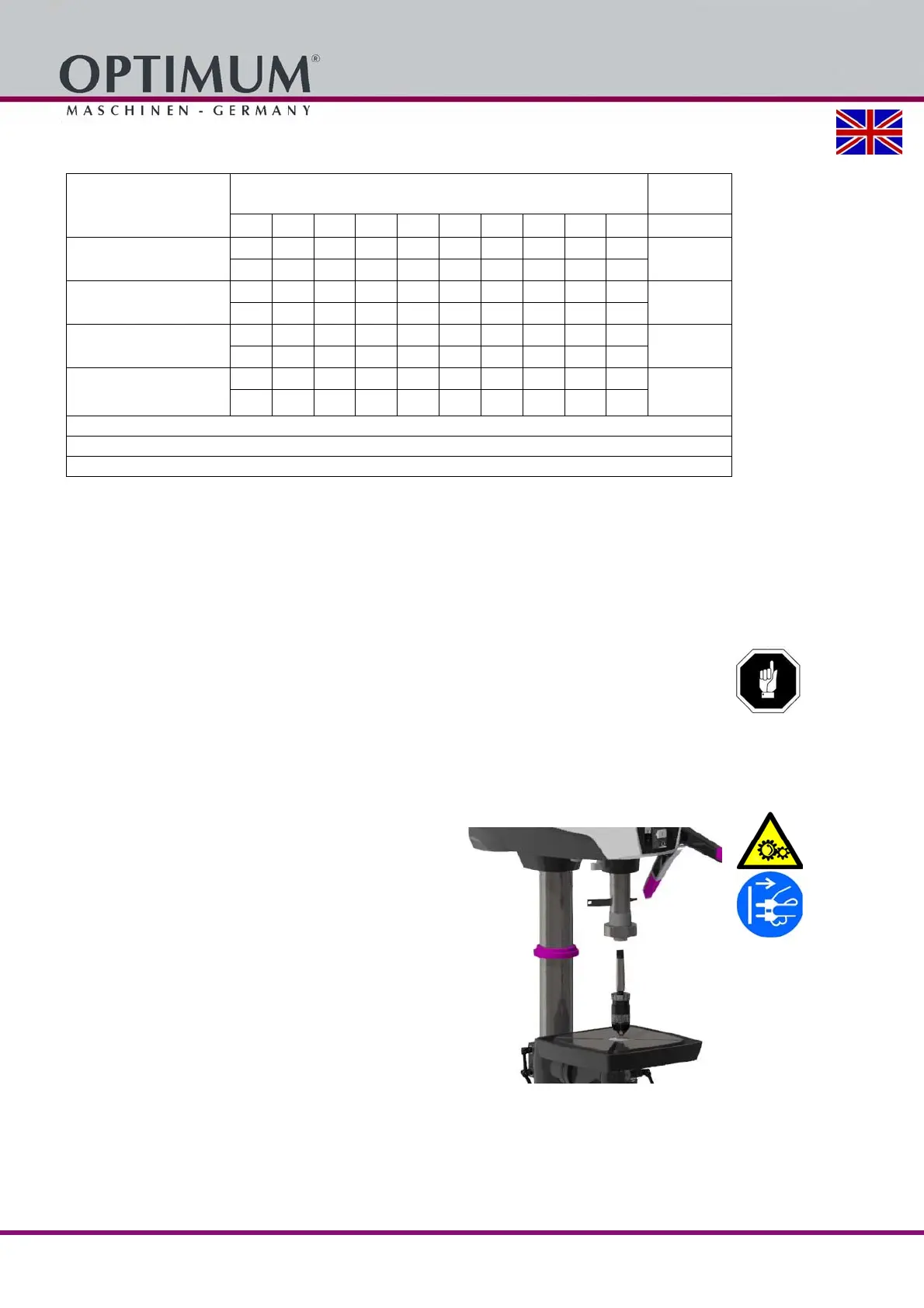

4.11.1 Unfitting the drill chuck

The drill chuck and the taper mandrel are loosened from the drill spindle by means of a drill

drift.

PRECAUTIONARY MEASURE

Only disassemble the drill chuck if the drilling

machine is disconnected from the electrical supply.

Disconnect the machine from the electrical supply.

Move the drill sleeve down.

Turn the drilling spindle until the openings of the

sleeve and of the drilling spindle are superimposed.

Loosen the taper mandrel of the drill chuck with the

help of a drill drift.

Material

Drill diameter

Cooling

3)

2345678910

Steel, unalloyed,

up to 600 N/mm

2

n

1)

5600 3550 2800 2240 2000 1600 1400 1250 1120

E

f

2)

0.04 0.063 0.08 0.10 0.125 0.125 0.16 0.16 0.20

Mild steel, alloyed, tempered,

up to 900N/mm

2

n 3150 2000 1600 1250 1000 900 800 710 630

E/oil

f 0.032 0.05 0.063 0.08 0.10 0.10 0.125 0.125 0.16

Mild steel, alloyed, tempered,

up to 1200 N/mm

2

n 2500 1600 1250 1000 800 710 630 560 500

Oil

f" 0.032 0.04 0.05 0.063 0.08 0.10 0.10 0.125 0.125

Stainless steels up to 900 N/

mm

2

e.g. X5CrNi18 10

n 2000 1250 1000 800 630 500 500 400 400

Oil

f 0.032 0.05 0.063 0.08 0.10 0.10 0.125 0.125 0.16

1): Speed [n] in rpm

2): Feed [f] in mm/rev

3): Cooling: E = Emulsion; oil = cutting oil

Loading...

Loading...