EN

47

EN

REV. 01 - Cod.: 1500288 Operation and maintenance manual / Ed. 11 - 2008

CUISSON SV-31 • SV-41

•

A

•

•

E

•

D

•

C

•

B

VACUUM PACKING GOODS IN A RIGID CONTAINER (VACUUM BOX)

USING THE APPLIANCE

1 Switch on the appliance and zero the sealing time.

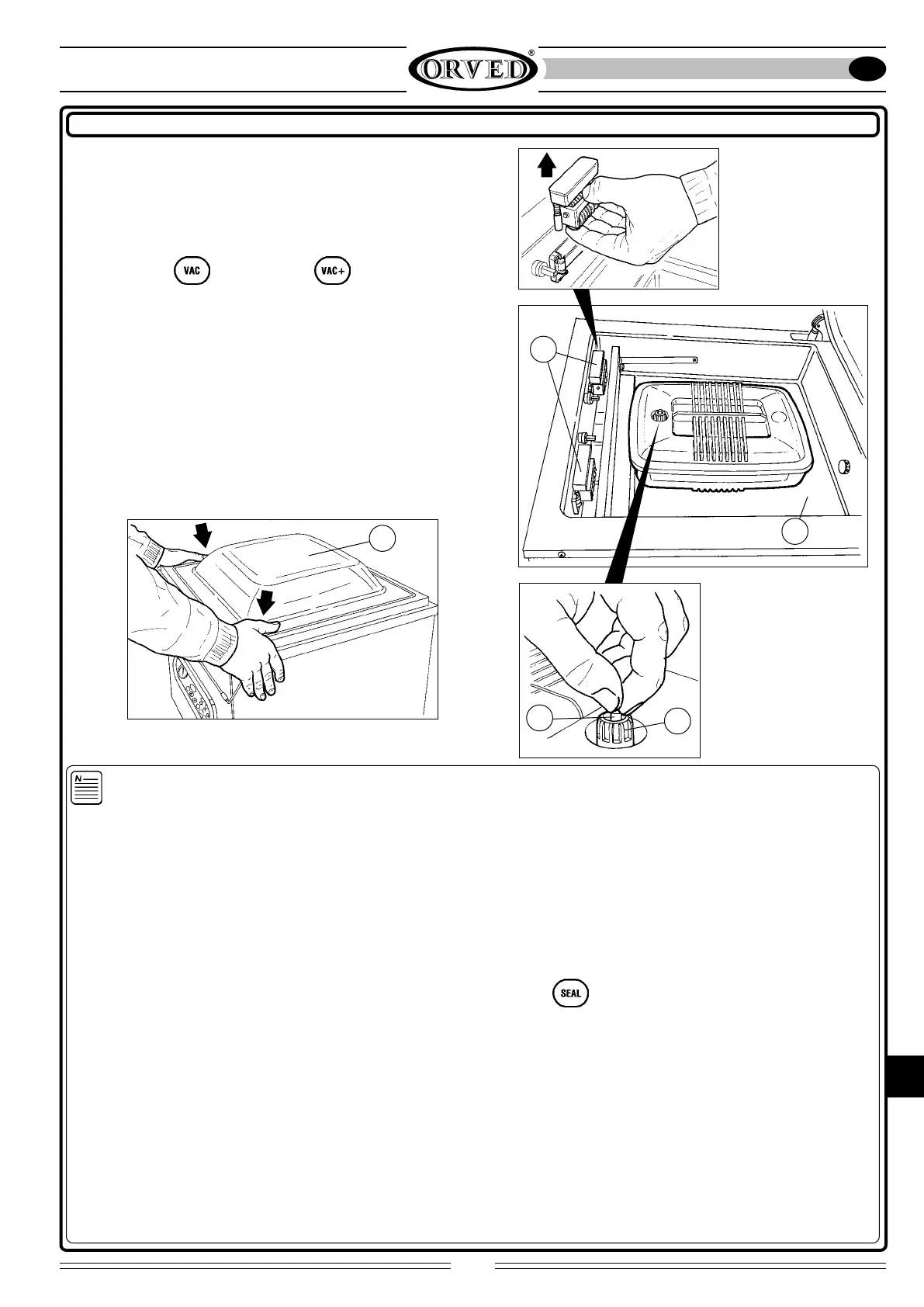

2 Deactivate the GAS function and remove both the dater stamp holders (A).

3 Prepare the lid of the container equipped with a valve by slightly unscrewing

the valve sealing ring (B) so that the plug it contains (C) is mobile.

4 Position the shelves (D) to suit the dimensions of the container (vacuum box).

5 Programme the functions and the functions if required.

6 WORK CYCLE START-UP:

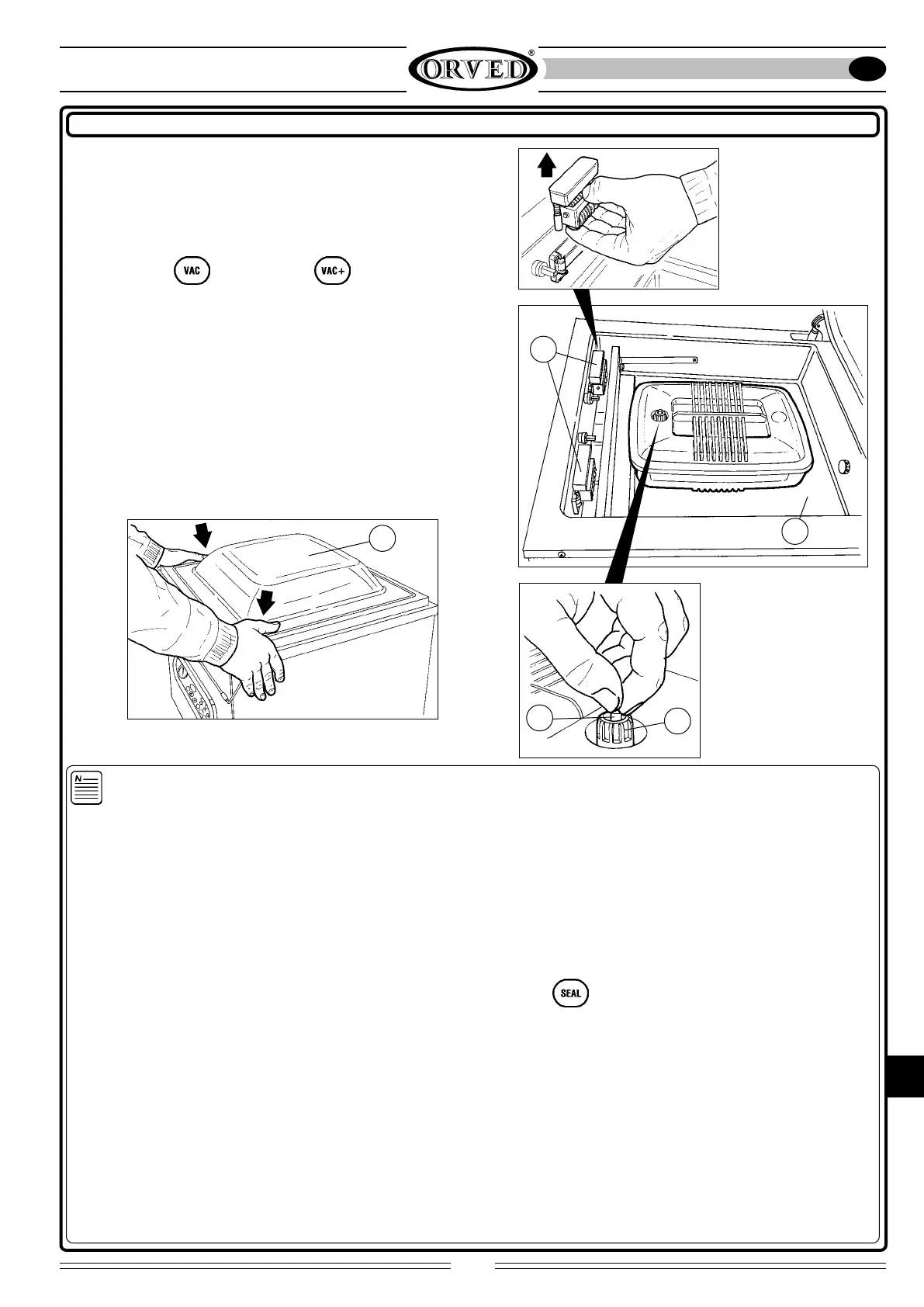

Lower the lid (E) using both hands, pressing it down lightly at the corners.

The appliance will start the work cycle according to the set parameters.

7 WORK CYCLE END:

The lid opens automatically when the cycle ends. Remove the container and

quickly tighten the valve sealing ring (B) to stop air from entering the container.

WARNINGS!

• SELECT BAGS OF A FORMAT AND THICKNESS WHICH BEST SUIT THE SIZE, RIGIDITY AND ANGULARITY OF THE PRODUCT.

WHEN USING THE VERTICAL COMPARTMENT, THE BAG MUST BE BIG ENOUGH TO ENSURE THAT THE OPENING CAN BE

INSERTED IN THE DATER.

• WHEN THE GAS FUNCTION IS ACTIVATED, THE LENGTH OF THE BAG MUST BE SUFFICIENT TO ENSURE THAT THE OPENING

CAN BE INSERTED IN THE DATER; THIS PREVENTS THE BAG FROM MOVING AWAY FROM THE SEALING BAR WHEN THE GAS

IS INJECTED.

• CARRY OUT PRELIMINARY SETTINGS BEFORE STARTING THE APPLIANCE.

• WHEN VACUUM PACKING A RIGID CONTAINER PLACED IN THE VACUUM CHAMBER, ZERO THE SEALING TIME, DEACTIVATE

THE GAS FUNCTION AND REMOVE THE DATER STAMP HOLDERS FROM THEIR SUPPORTS.

• THE WORK CYCLE CAN BE STOPPED AT ANY MOMENT BY PUSHING THE

KEY.

• IF THE LID OPENS DURING THE GAS FLUSHING CYCLE, REDUCE THE GAS FLUSHING TIME.

• WHEN CARRYING OUT NUMEROUS SUCCESSIVE WORK CYCLES, REDUCE THE SEALING TIME TO AVOID THE APPEARANCE OF

MELTING POINTS ALONG THE BAG’S SEALING LINE.

• FOR A CORRECT CHOICE OF THE GAS MIXTURE TO BE USED DEPENDING ON THE FOODS TO BE PRESERVED, REFER TO THE

LEAFLETS DISTRIBUTED BY THE GAS PRODUCERS.

• USE OF GAS MIXTURES CONTAINING OXYGEN OR OTHER EXPLOSIVE GASES IS SEVERELY PROHIBITED.

• AVOID LIQUIDS FROM LEAKING OUT OF BAGS BY SELECTING A BAG FORMAT WHICH IS SUITABLE FOR THE VOLUME OF

PRODUCT TO BE PACKAGED. THE HIGHER THE DENSITY OF THE PRODUCT (SAUCES, DRESSINGS ETC.), THE LOWER THE

VOLUME WHICH CAN BE PACKAGED . (MAX. 5 LT FOR PRODUCTS WITH A DENSITY SIMILAR TO THAT OF WATER, MAX. 4 LT

FOR SAUCES AND DRESSINGS).

• IF THE APPLIANCE OVERHEATS IT MAY ASSUME ALARM STATUS AS SHOWN BY THE FLASHING MESSAGE “ALL”. FOLLOW

THE STEPS ILLUSTRATED ON PARAGRAPH 5.3.

Loading...

Loading...