FOREST CRANE PALMS 840

V 1.03 EN 2012 Palmse Mehaanikakoda LLC 8

4. ASSEMBLY AND MOUNTING

Read these instructions before starting any assembly or mounting of crane. Improper

mounting, carried out in a manner other than specified in this manual, may cause

dangerous situations to user and surrounding objects. Improper mounting, useage and

installations will void the manufacturer warranty.

4.1 Mounting forest crane to Palms trailer

Mounting of forest crane should be performed at the dealer service center or by person

authorized by the manufacturer or dealer. Mounting/detaching the crane can also be

made by end user, if professional equipment is used, all safety regulations are followed

and at least one qualified mechanic is present during all the mounting/detaching process.

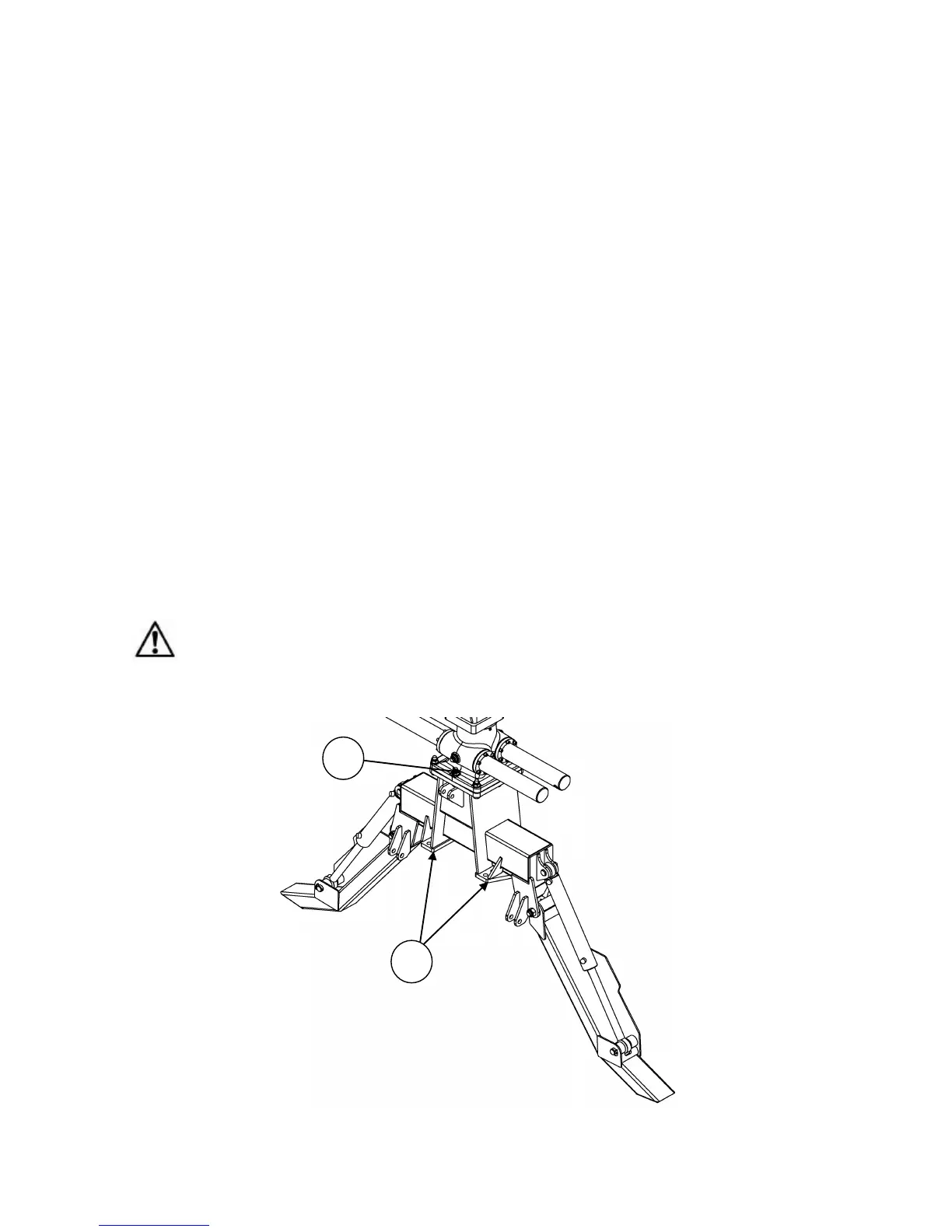

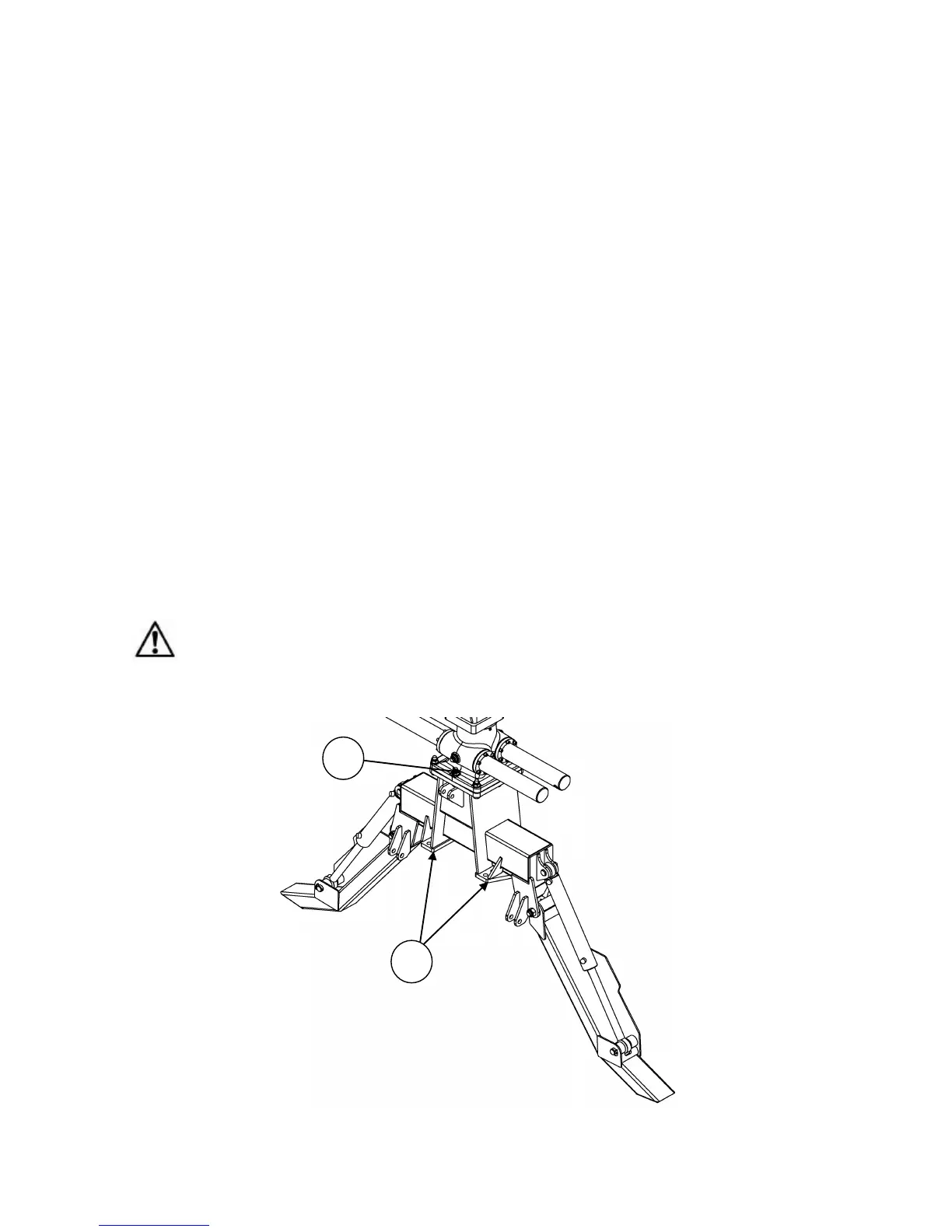

Strength class for mounting bolts of slewing device-support legs (pos. 1, fig.5) and

support legs-trailer (pos. 2, fig. 5) has to be 12.9 (DIN912). Use self-locking nuts M24.

The tightening torque for the mounting bolts of the crane (pos. 1, fig. 5) and supporting

legs (pos. 2, fig. 5) is 1220 Nm.

Retighten bolts after the test run and after first 8 hours of use! Check after

40 working hours, tighten if needed. Visual check is required prior every

working session.

Figure 5. Connection junctions on Palms 840 support legs

Loading...

Loading...