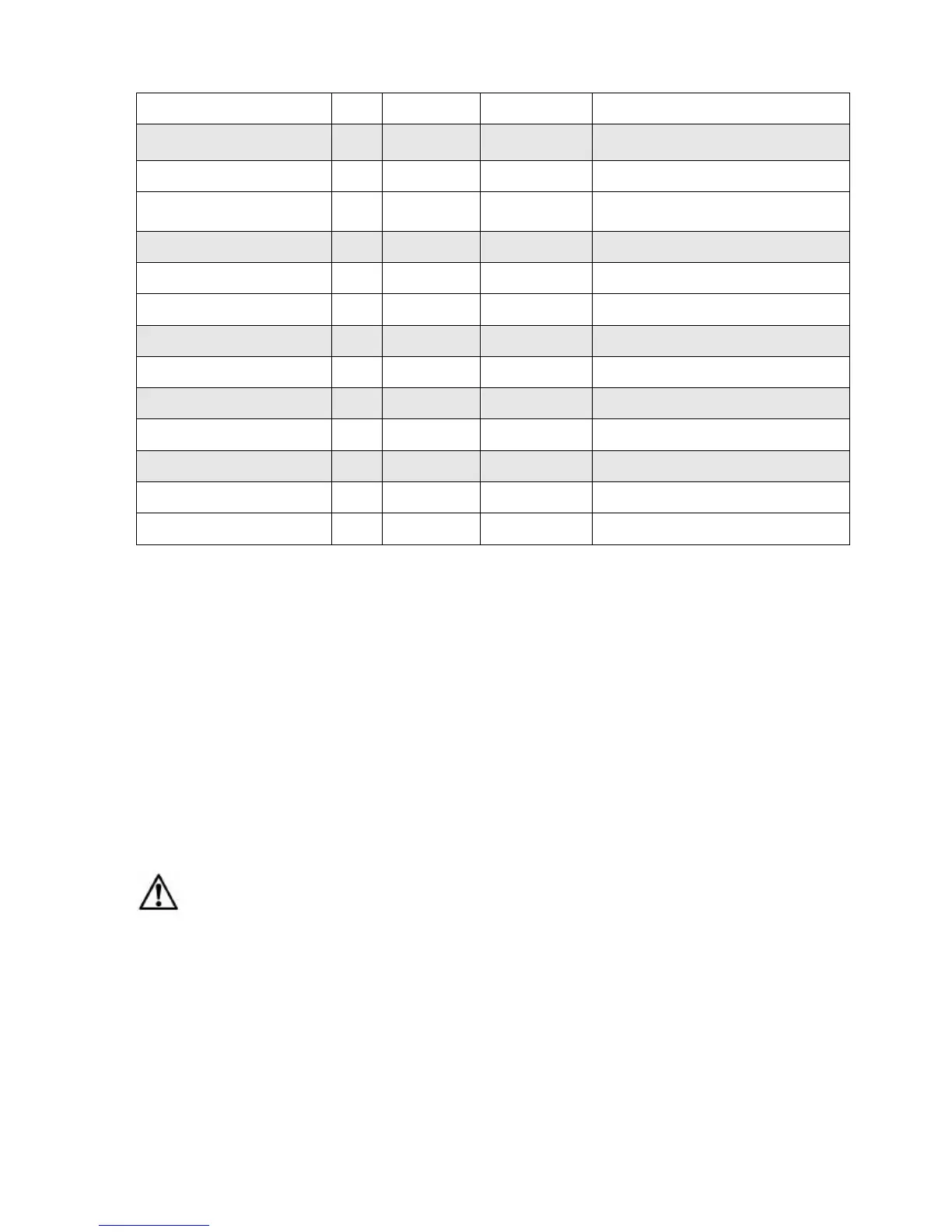

Table 5. Oil and lubricant grade table of Palms 840

9.5 Changing the hydraulic oil

Change hydraulic oil at least once in two years. Forest crane hydraulic system has been

filled with Addinol HVLP ISO VG. 32 (DIN 51524/3) hydraulic oil at the factory. Oil

temperature should not exceed 75°C in summer, winter oil can be used all year round.

We recommend to use high pressure oil filter with indicator (which shows, when filter

element is dirty and needs to be changed).

9.6 Hydraulic oil requirements

Freezing point must be below -50C.

Viscosity must not be lower than 1.5 E, +50C for piston pumps and 2.5 E°,

+ 50°C for gear pumps.

Hydraulic oil must contain the necessary additives for lubrication, rust

protection and defoaming.

Loading...

Loading...