Check mounting bolts, tighten if needed.

Check gear racks, adjust if needed

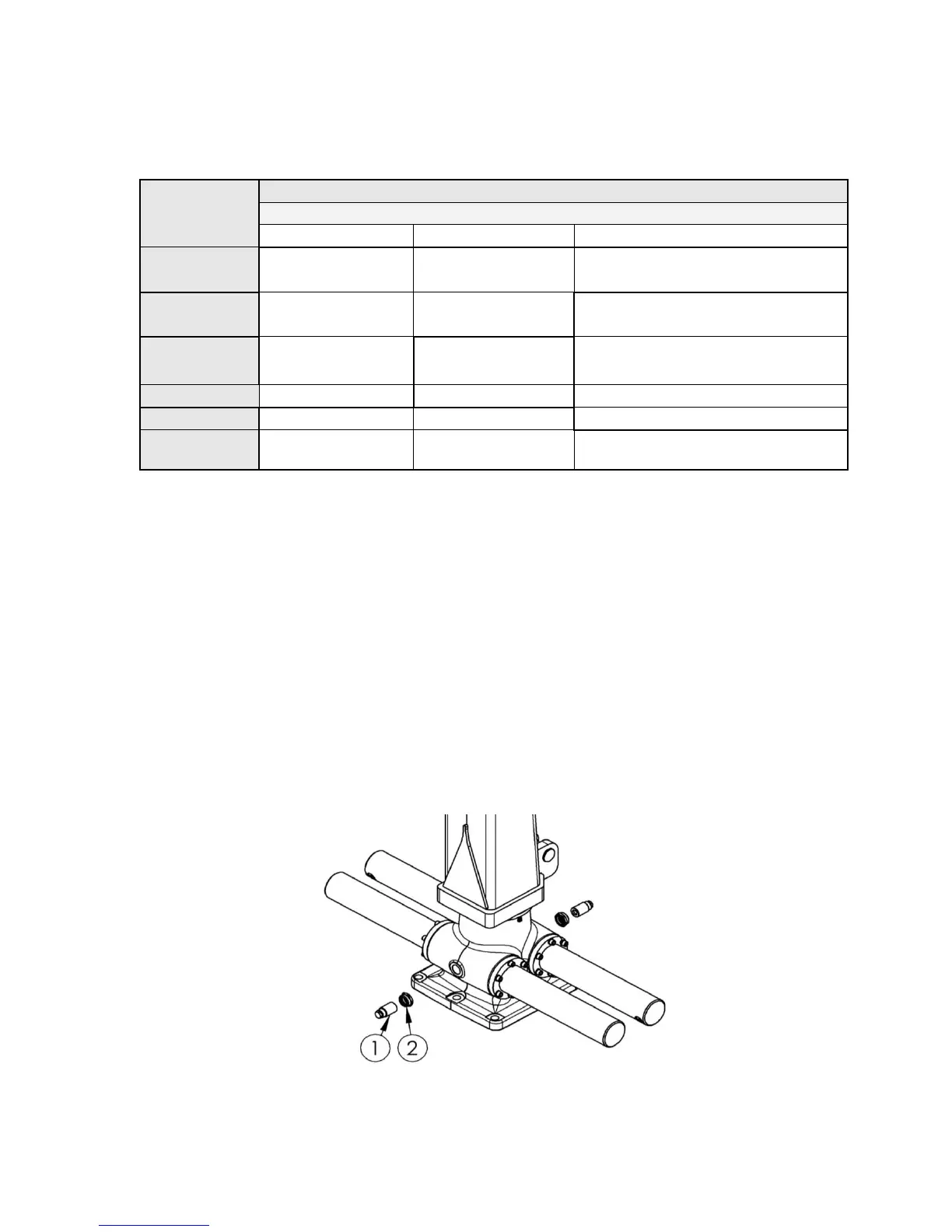

Table 4. Maintenance table

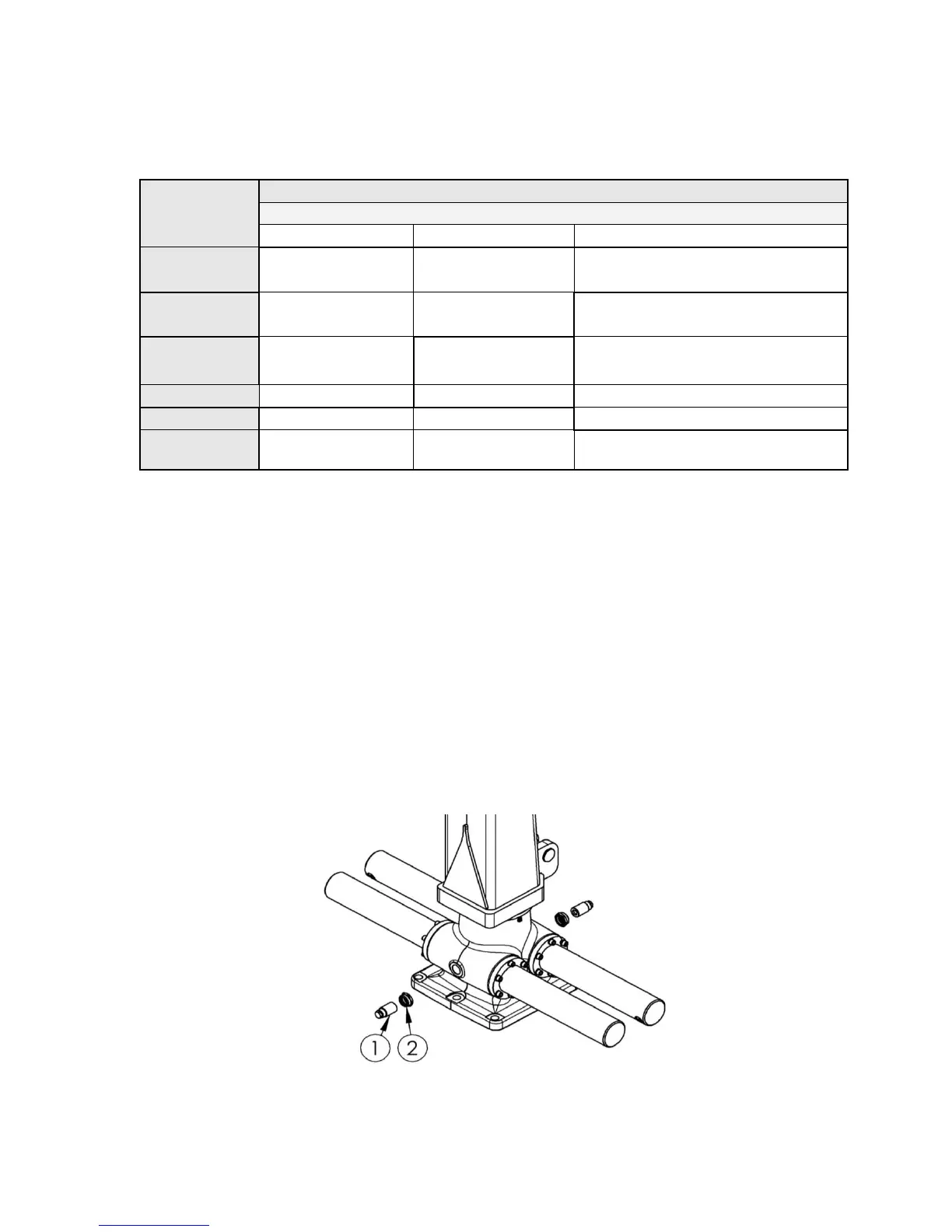

9.2 Adjusting the gear racks

Turn column into center position.

Release the locking nut widely enough, so it will not obstruct tightening (pos. 2 fig. 17).

Tighten the bolt (pos. 1, fig. 17) against the gear rack with 20-25 Nm (2-2,5 kg*m).

Tighten the locking nut (pos. 2 fig. 17).

Repeat same procedure with both bolts.

Make sure you adjust bolts after every 200 working hours.

With professional everyday usage, tighten bolt at least once a month.

Figure 17. Adjusting racks of slewing device

Loading...

Loading...