36

11.2.3 Connect the Piping

11.2.3.1 Connecting the Piping to Indoor Unit

Please make flare after inserting flare nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

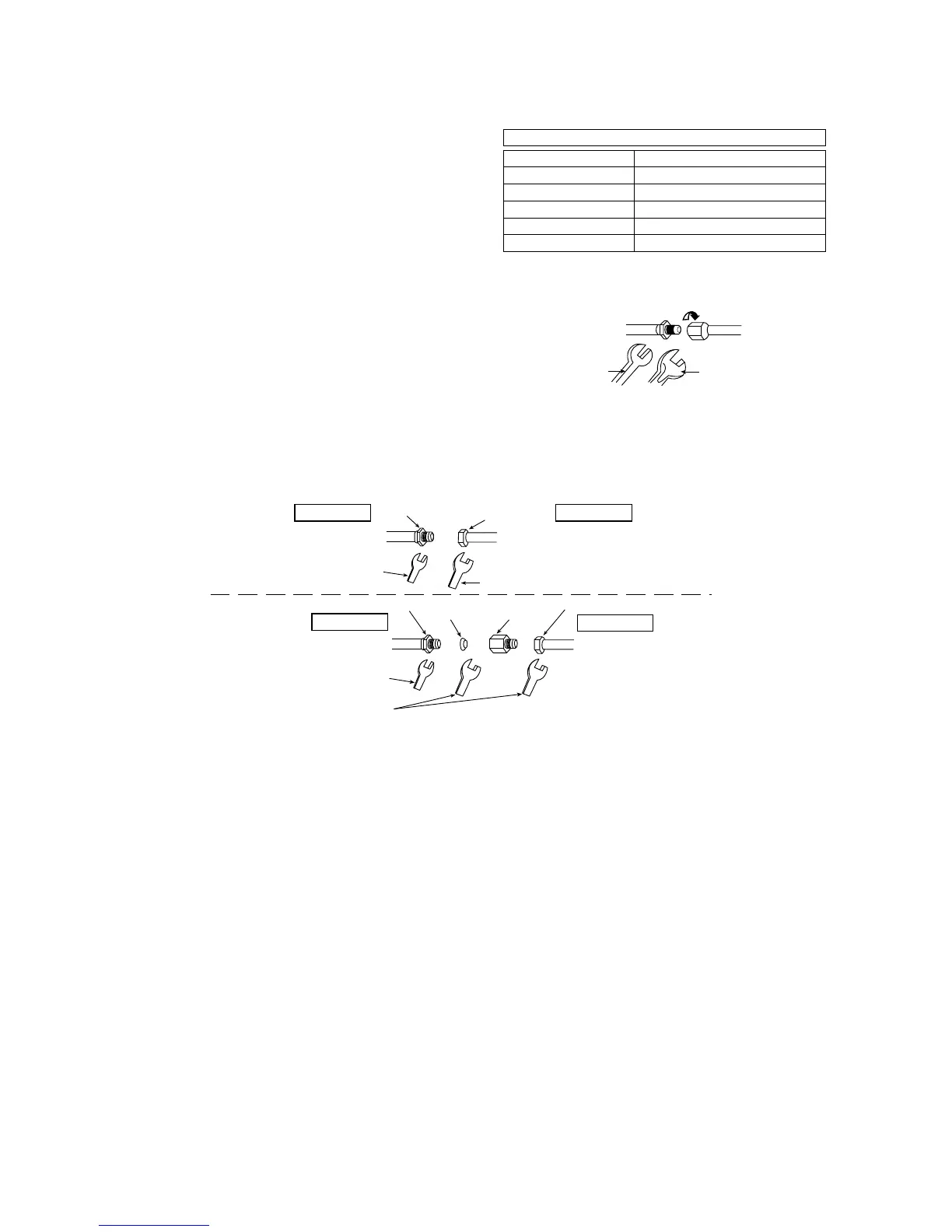

Align the center of piping and sufficiently tighten

the flare nut with fingers.

Further tighten the flare nut with torque wrench in

specified torque as stated in the table.

Do not overtighten, overtightening may cause gas leakage

Piping size Torque

1/4" (6.35 mm) 13.3 Ibf•ft [18 N•m (1.8 kgf•m)]

3/8" (9.52 mm) 31.0 Ibf•ft [42 N•m (4.3 kgf•m)]

1/2" (12.7 mm) 40.6 Ibf•ft [55 N•m (5.6 kgf•m)]

5/8" (15.88 mm) 47.9 Ibf•ft [65 N•m (6.6 kgf•m)]

3/4" (19.05 mm) 73.8 Ibf•ft [100 N•m (10.2 kgf•m)]

11.2.3.2 Connecting the Piping to Outdoor Unit

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge. Make flare after

inserting the flare nut (locate at valve) onto the copper

pipe. Align center of piping to valve and then tighten

with torque wrench to the specified torque as stated in

the table.

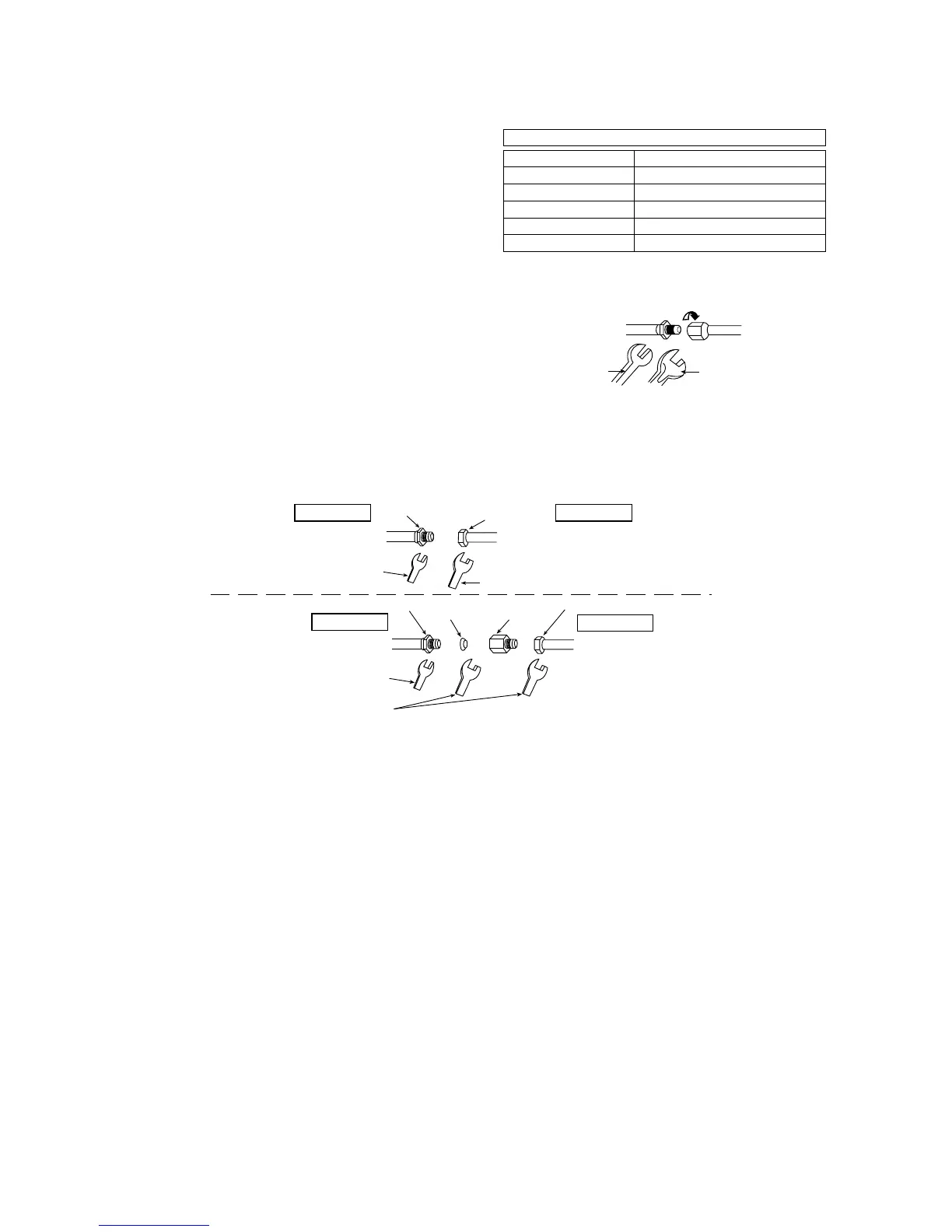

11.2.3.3 Connecting the Piping to Outdoor Multi

Decide piping length and then cut by using pipe cutter. Remove burrs from cut edge. Make flare after inserting the

flare nut (locate at valve) onto the copper pipe. Align center of piping to valve and then tighten with torque wrench to

the specified torque as stated in the table.

11.2.3.4 Gas Leak Checking

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system.

If the pressure holds, release the nitrogen and proceed to section 11.2.4.

Torque wrench

Spanner

or Wrench

Female side

Male side

Female sideMale side

(Connection pipe)

(Auxiliary pipe)

(Auxiliary pipe)

Wrench (Adjustable Wrench)

Wrench (Adjustable Wrench)

Torque Wrench f or Flare Nut

Applicable to

Liquid side of

CS-E12***

CS-E18***

Applicable to

Gas side of

CS-E12***

CS-E18***

Torque Wrench for Flare Nut

Loading...

Loading...