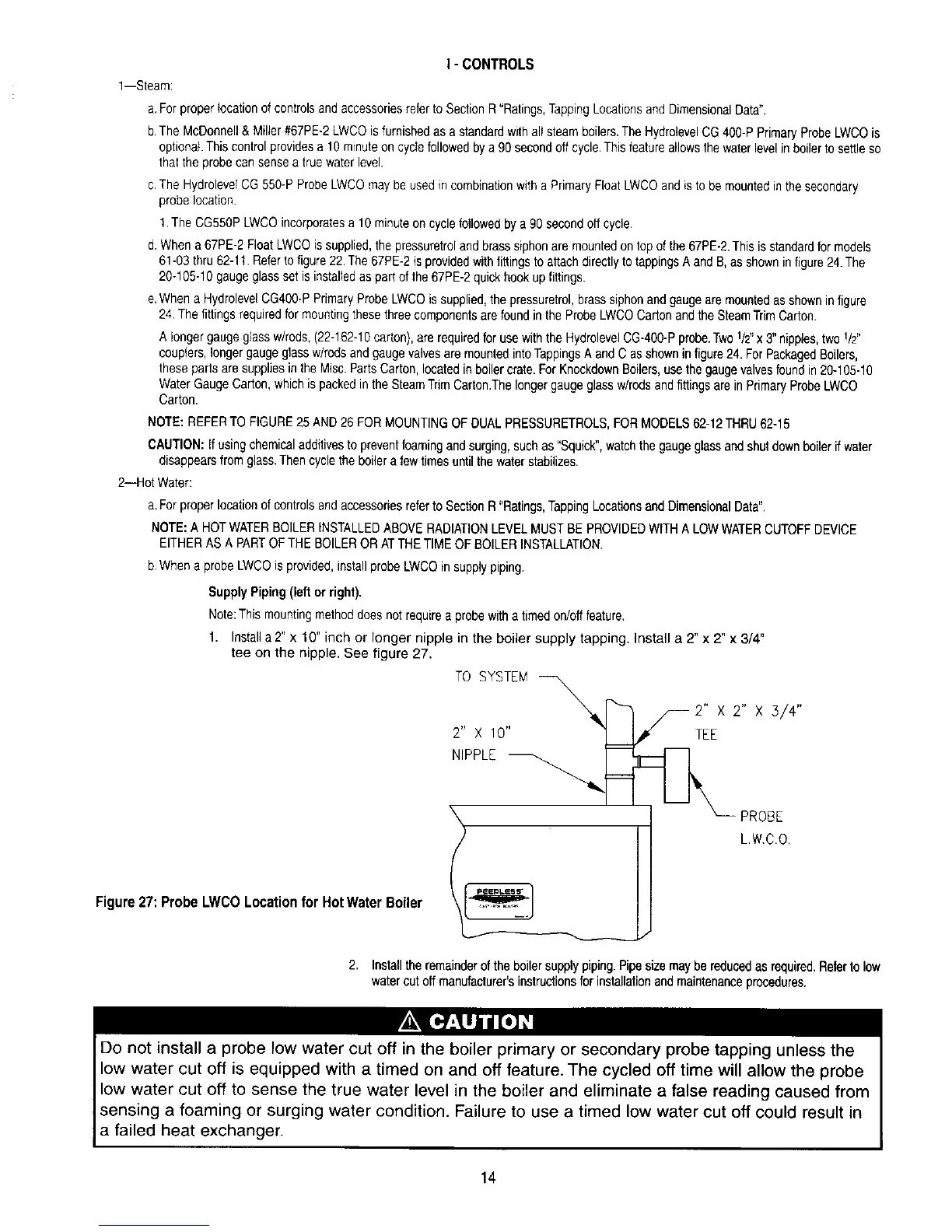

Figure27:ProbeLWCOLocationfor HotWaterBoiler

I - CONTROLS

l--Steam:

a.Forproper}ocationof controlsand accessoriesreferto SectionR "Ratings,TappingLocationsandDimensionalData".

b.TheMcDonnell& Miller#67PE-2LWCOisfurnishedas a standardwith all steamboilers.The HydrolevelCG400-PPrimaryProbeLWCOis

optional.This controlprovidesa lg minuteon cyciefollowedby a 90secondoffcycle.Thisfeatureallowsthe waterlevelinboilerto settleso

that theprobe cansensea truewaterlevel.

c.TheHydrolevelCG550-P ProbeLWCOmaybeusedin combinationwith a PrimaryFloatLWCOand is to bemountedinthe secondary

probe location.

1.TheCG550PLWCOincorporatesa 10minuteon cyclefollowedbya 90secondoff cycle.

d.Whena 67PE-2FloatLWCOis supplied,the pressuretroland brasssiphonare mountedontop ofthe 67PE-2.Thisisstandardformodels

61-03thru 62-1t. Referto figure22.The67PE-2is providedwith fittingsto attachdirectlyto tappingsA and B,as shownin figure24.The

20q 05-10gaugeglassset isinstalledas partof the67PE-2quickhook upfittings.

e.Whena HydrolevelCG400-PPrimaryProbeLWCOis supplied,the pressuretrol,brasssiphonand gaugeare mountedasshowninfigure

24.The fittingsrequiredfor mountingthesethreecomponentsare foundinthe ProbeLWCOCartonand theSteamTrimCarton.

A longergaugeglassw/rods,(22-162-10carton),are requiredfor usewith the HydrolevelCG-400-Pprobe.Two1/2"x 3" nipples,two 1/2"

couplers,longergaugeglassw/rodsand gaugevalvesare mountedintoTappingsA andCas showninfigure24.ForPackagedBoilers,

theseparts are suppliesin the Misc.PartsCarton,locatedin boilercrate.ForKnockdownBoilers,usethegaugevalvesfoundin20-105-10

WaterGaugeCarton,whichis packedin the SteamTrimCarton.Thelongergaugeglassw/rodsandfittingsare in PrimaryProbeLWCO

Carton.

NOTE:REFERTO FIGURE25 AND26 FORMOUNTINGOFDUALPRESSURETROLS,FORMODELS62-12THRU62-15

CAUTION:Ifusingchemicaladditivesto preventfoamingand surging,suchas "Squick",watchthe gaugeglassandshutdownboilerif water

disappearsfrom glass.Thencyclethe boilera fewtimesuntilthe waterstabilizes.

2--Hot Water:

a.Forproperlocationof controlsand accessoriesreferto SectionR "Ratings,TappingLocationsand DimensionalData".

NOTE:A HOTWATERBOILERINSTALLEDABOVERADIATIONLEVELMUSTBEPROVIDEDWITHA LOWWATERCUTOFFDEVICE

EITHERAS A PARTOF THEBOILERORATTHETIMEOFBOILERINSTALLATION.

b.Whena probe LWCOis provided,installprobeLWCOin supplypiping.

Supply Piping (left or right).

Note:This mountingmethoddoesnot requirea probewitha timed on/offfeature.

1. Instal_a 2" x 10" inch or longer nipple in the boiler supply tapping. Install a 2" x 2" x 3/4"

tee on the nipple. See figure 27.

TO SYSTEM

__ 2,,x

2 X 10 ] I,P" TEE

NIPPLE _

RO Eo'

2. Installtheremainderof the boilersupplypiping.Pipesizemaybe reducedasrequired.Referto low

watercut off manufacturer'sinstructionsfor installationandmaintenanceprocedures.

Do not install a probe low water cut off in the boiler primary or secondary probe tapping unless the

low water cut off is equipped with a timed on and off feature. The cycled off time will allow the probe

low water cut off to sense the true water level in the boiler and eliminate a false reading caused from

sensing a foaming or surging water condition. Failure to use a timed low water cut off could result in

a failed heat exchanger.

14

Loading...

Loading...