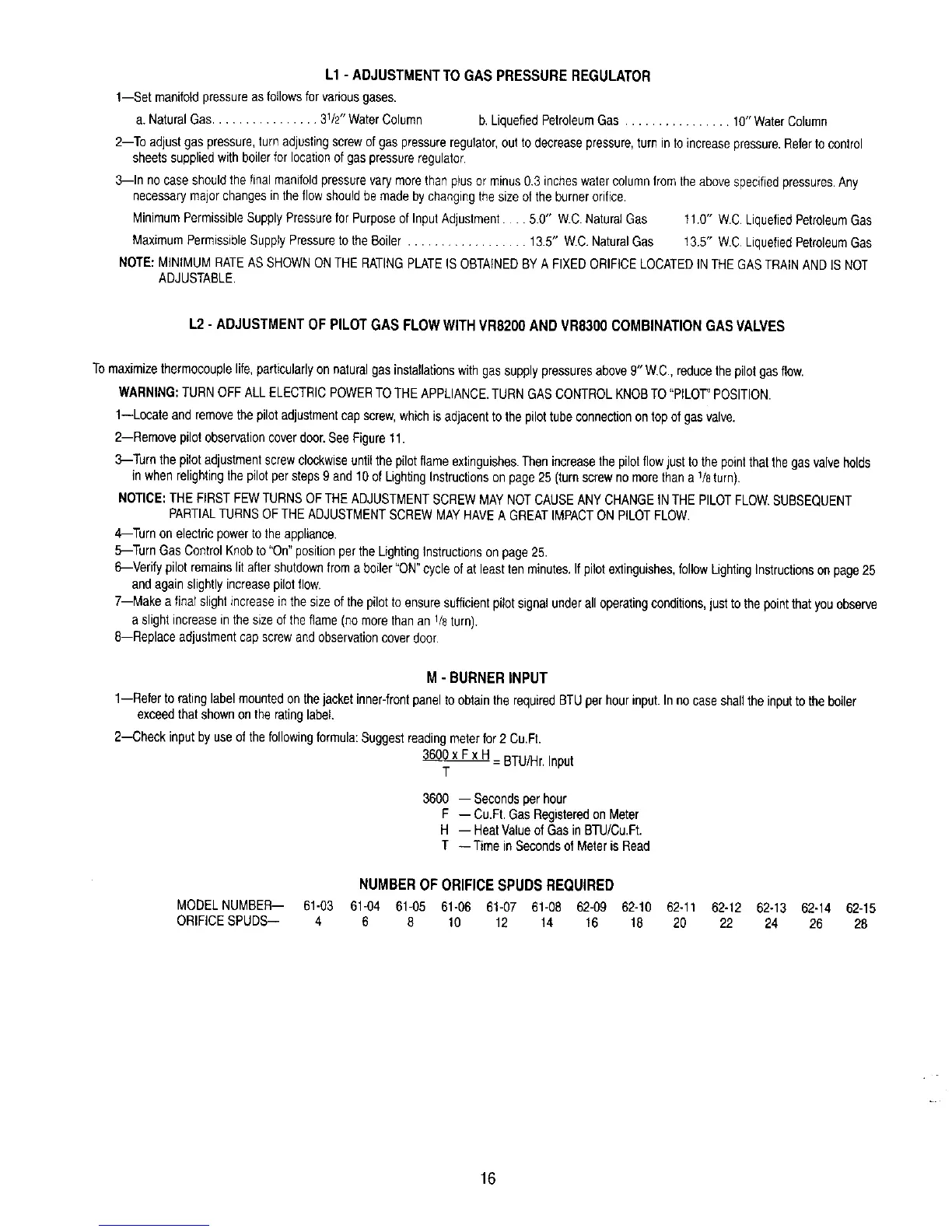

L1 - ADJUSTMENT TO GAS PRESSURE REGULATOR

1--Set manifoldpressureasfo_lowsfor variousgases.

a.NaturalGas................ 31/2"WaterColumn b,LiquefiedPetroleumGas ................ 10" WaterColumn

2--To adjustgaspressure,turn adjustingscrewof gaspressureregulator,outto decreasepressure,turnin toincreasepressure,Referto control

sheetssuppliedwith boilerfor locationofgas pressureregulator•

3--In no caseshouldthe finalmanifoldpressurevarymorethan plusor minus03 incheswatercolumnfromtheabovespecifiedpressures•Any

necessarymajorchangesinthe flowshouldbemadeby changingthe sizeofthe burnerorifice.

MinimumPermissibleSupplyPressurefor Purposeof InputAdjustment.... 5.0" W.C.NaturalGas 11.0" W.C LiquefiedPetroleumGas

MaximumPermissibleSupplyPressureto the Boiler .................. 13.5" W.C.NaturalGas 13.5" W.C LiquefiedPetroleumGas

NOTE: MINIMUMRATEASSHOWNONTHE RATINGPLATE!S OBTAINEDBY A FIXEDORIFICELOCATEDINTHEGASTRAINANDIS NOT

ADJUSTABLE•

L2- ADJUSTMENTOFPILOTGASFLOWWITHMR8200AND MR8300COMBINATIONGASVALVES

To maximizethermocouplelife,particularlyonnaturalgasinstallationswith gassupplypressuresabove9" W,C.,reducethepilot gasflow.

WARNING:TURNOFFALL ELECTRICPOWERTOTHEAPPLIANCE.TURNGASCONTROLKNOBTO "PILOT'POSITION•

1--Locate and removethe pilotadjustmentcapscrew,whichisadjacenttothepilottube connectionontopof gasvalve.

2--Remove pilot observationcoverdoor.SeeFigure11.

3--Turn the pilotadjustmentscrewclockwiseuntilthe pilot flameextinguishes•Then increasethe pilotflow just to thepointthatthegasvalveholds

in whenrelightingthe pilotpersteps9 and 10of LightingInstructionsonpage25 (turnscrewno morethana 1/8turn).

NOTICE:THE FIRSTFEWTURNSOFTHEADJUSTMENTSCREWMAYNOTCAUSEANYCHANGEINTHEPILOTFLOW.SUBSEQUENT

PARTIALTURNSOFTHE ADJUSTMENTSCREWMAYHAVEA GREATIMPACTON PILOTFLOW.

4--Turn on electricpowerto the appliance.

5--Turn Gas ControlKnobto"On"positionper the LightingInstructionsonpage 25.

6--Verify pilot remainslitaftershutdownfroma boiler"ON"cycleofat leasttenminutes,If pilot extinguishes,followLightingInstructionsonpage25

and again slightlyincreasepilotflow.

7--Make a fina_slightincreaseinthe sizeofthe pilotto ensuresufficientpilot signalunderalloperatingconditions,justtothepointthat youobserve

a slight increasein thesizeof theflame (nomore thanan 1/8turn).

8--Replace adjustmentcapscrewandobservationcover door•

M-BURNERINPUT

1--Refer to ratinglabelmountedon thejacketinner-frontpanelto obtainthe requiredBTUper hourinput•Innocaseshallthe inputtotheboiler

exceedthat shownonthe ratinglabel.

2--Check input by useofthefollowingformula:Suggestreadingmeterfor2 Cu.Ft.

_Q0 x Fx H_ BTU/Hr.Input

T

3600 -- Secondsperhour

F -- Cu.Ft.GasRegisteredonMeter

H -- HeatValueof Gas inBTU/Cu.Fb

T -- TimeinSecondsof MeterisRead

NUMBER OF ORIFICE SPUDS REQUIRED

MODELNUMBER-- 61-03 61-04 61-05 61-06 61-07 61-08 62-09 62-10 62-11 62-12 62-13 62-14 62-15

ORIFICESPUDS-- 4 6 8 10 12 14 16 18 20 22 24 26 28

• k

16

Loading...

Loading...