SEBU8121 15

Product Information Section

Model Views

i02247483

Engine Description

The Perkins110

4 Electronic Engine is designed for

the following applications: machine and industrial

mobile equipment. The engines are available in the

following typ

es of aspiration:

•

Turbocharged aftercooled

•

Turbocharged

•

Naturally asp

irated

Engine Specif

ications

Note: The front end of the engine is opposite the

flywheel end

of the engine. The left and the right

sides of the engine are determined from the flywheel

end. The number 1 cylinder is the front cylinder.

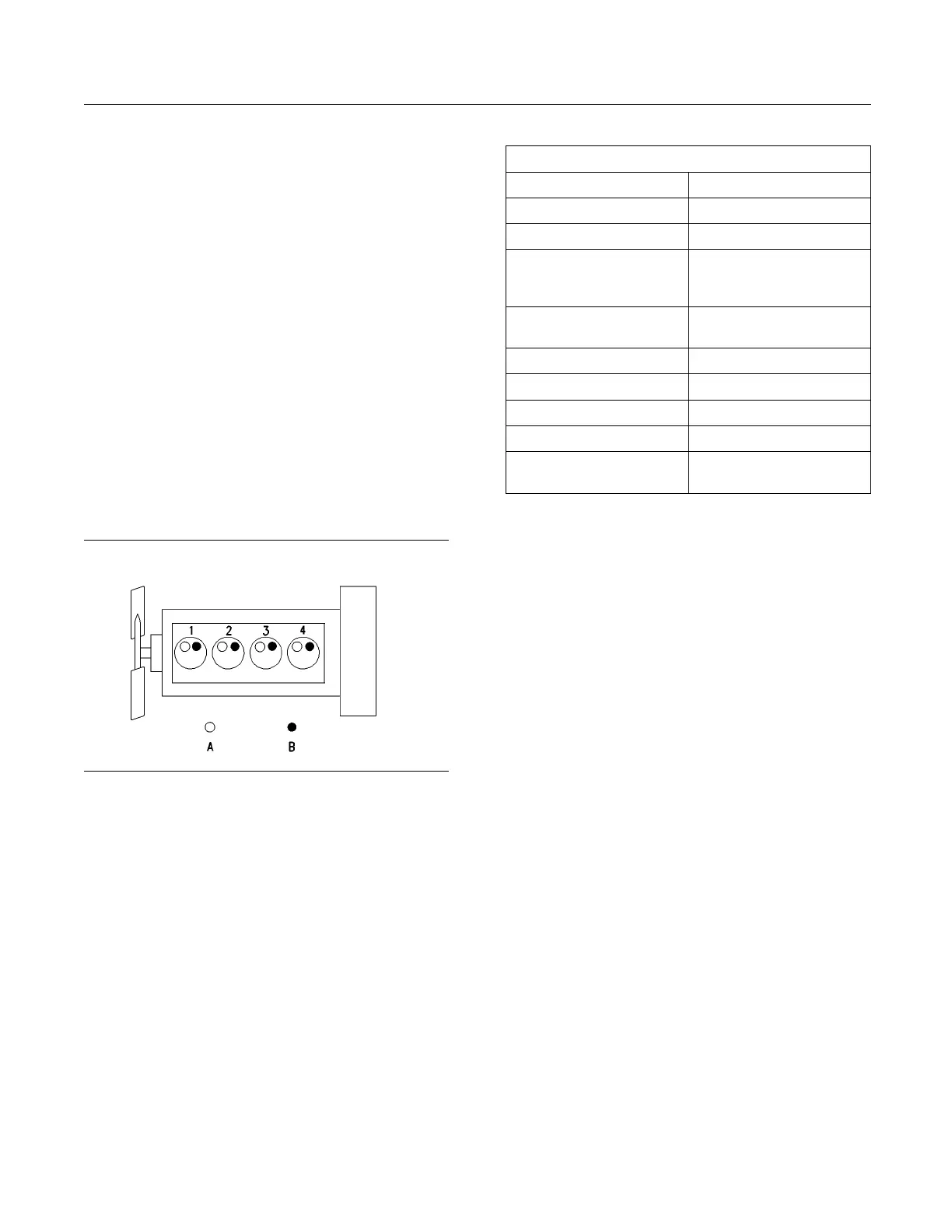

g00984281

Illustration 10

Typical example

1104 Electronic engine

(A) Inlet valves

(B) Exhaust v alves

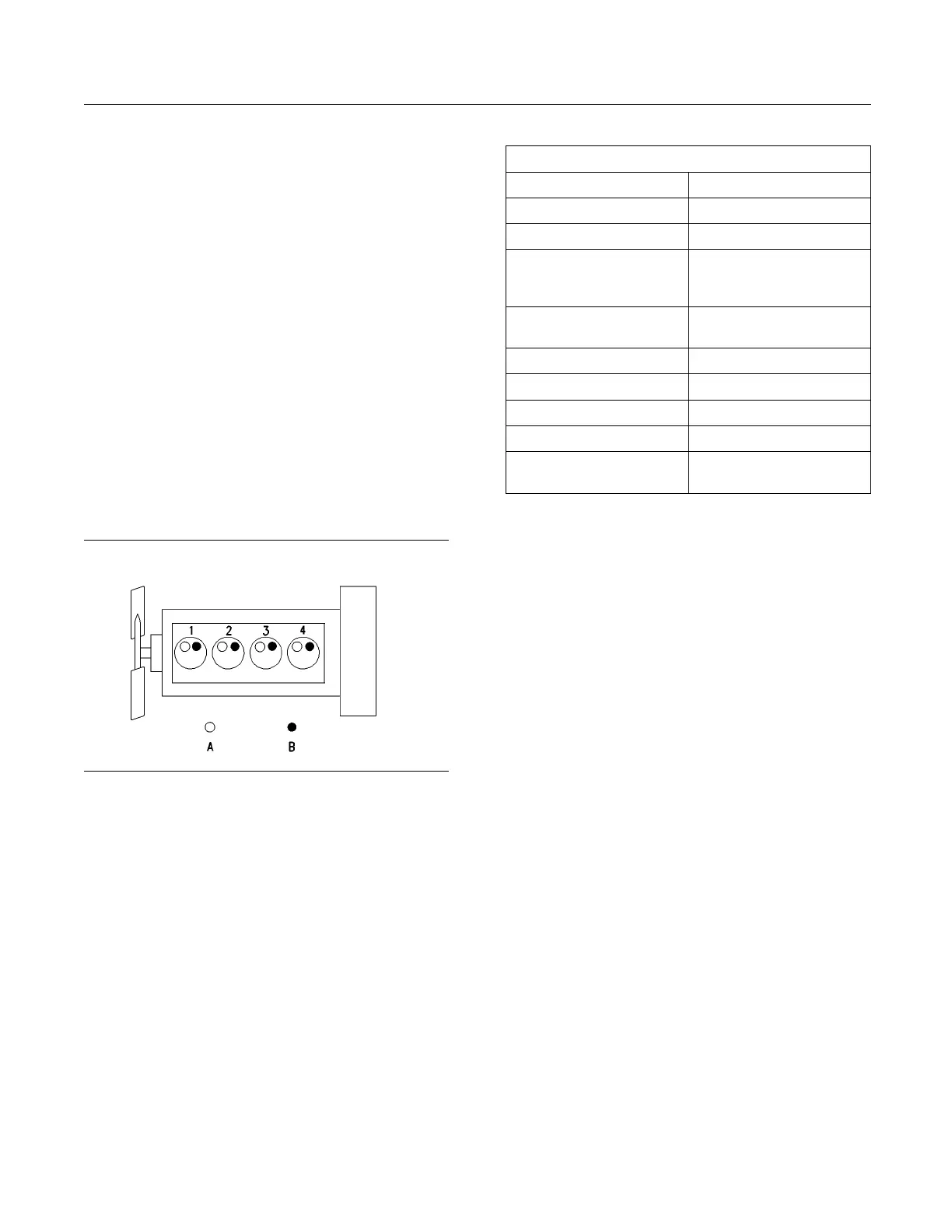

Table 1

1104 Electronic Engine Specifications

Number of Cylinders 4 In-Line

Bore

105 mm (4.134 inch)

Stroke 127 mm (5.0 inch)

Aspiration

Turbocharged, aftercooled

Turbocharged

Naturall y aspirated

Compression

Ratio

NA 19.25:1 NA

T 18.23:1 T, TA

Displacement

4.4L(268in

3

)

Firing Order 1-3-4-2

Rotation (flywheel end) Counterclockwise

Valve Lash Setting (Inlet) 0.20 mm (0.008 inch)

Valve Lash Setting

(Exhaust)

0.45 mm (0.018 inch)

E

lectronic Engine Features

The Perkins 1104 Electronic Engine is designed with

e

lectronic controls. The integral on board computer

controls the operation of the engine. Current

operating conditions are monitored. The Electronic

Control Module (ECM) controls the response of the

engine to these conditions and to the demands of the

operator. These conditions and operator demands

determine the precise control of fuel injection by the

ECM. The electronic engine control system provides

the following features:

•

Engine monitoring

•

Engine speed governing

•

Cold start strategy

•

Automatic air/fuel ratio control

•

Torque rise shaping

•

Automatic altitude compensation

•

Fuel temperature compensation

•

Injection timing control

•

System diagnostics

For more information on electronic engine features,

refer to the Operation and Maintenance Manual,

“Features and Controls” topic (Operation Section).

Loading...

Loading...