SEBU8121 45

Maintenance Section

Refill Capacities

The preferred f

uels provide maximum engine service

life and performance. The preferred fuels are distillate

fuels. These fuels are commonly called diesel fuel

or gas oil.

The permissible fuels are crude oils or blended fuels.

Use of these f

uels can result in higher maintenance

costs and in reduced engine service life.

Diesel fuels

that meet the specifications in Table

8willhelptoprovidemaximumengineservicelife

and performance. In North America, diesel fuel that

is identifie

d as No. 2-D in “ASTM D975” generally

meets the specifications. Table 8 is for diesel fuels

that are distilled from crude oil. Diesel fuels from

other sourc

es could exhibit detrimental properties

that are not defined or controlled by this specification.

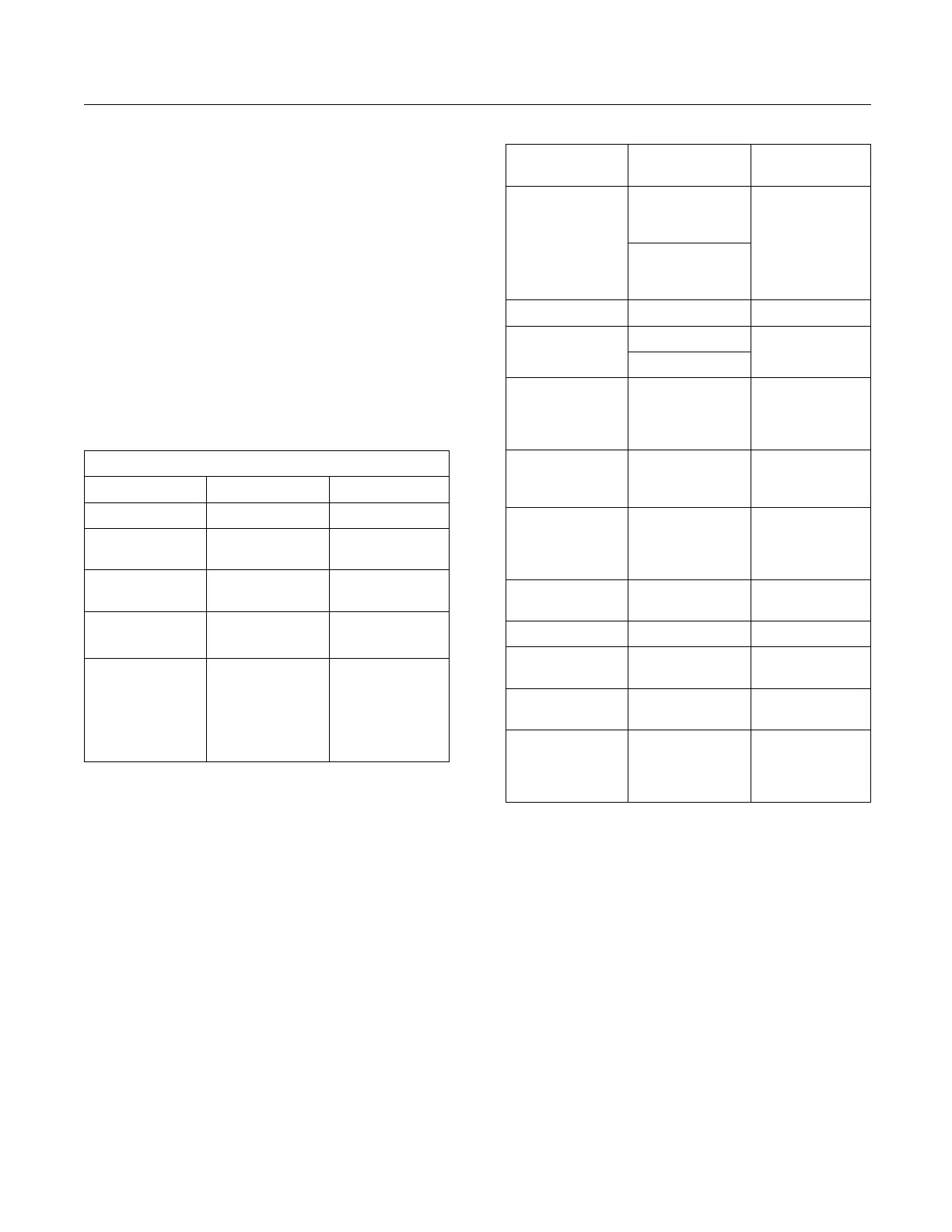

Table 8

Perkins Specifications for Distillate Diesel Fuel

Specifica

tions

Requirements

ASTM Test

Aromatics 35% maximum “D1319”

Ash

0.02% maximum

(weight)

“D482”

Carbon Residue

on 10% Bottoms

0.35% maximum

(weight)

“D524”

Cetane Number

40 minimum (DI

engines)

“D613”

Cloud Point

The cloud

point must not

exceed the

lowest expected

ambient

temperature.

-

(continued)

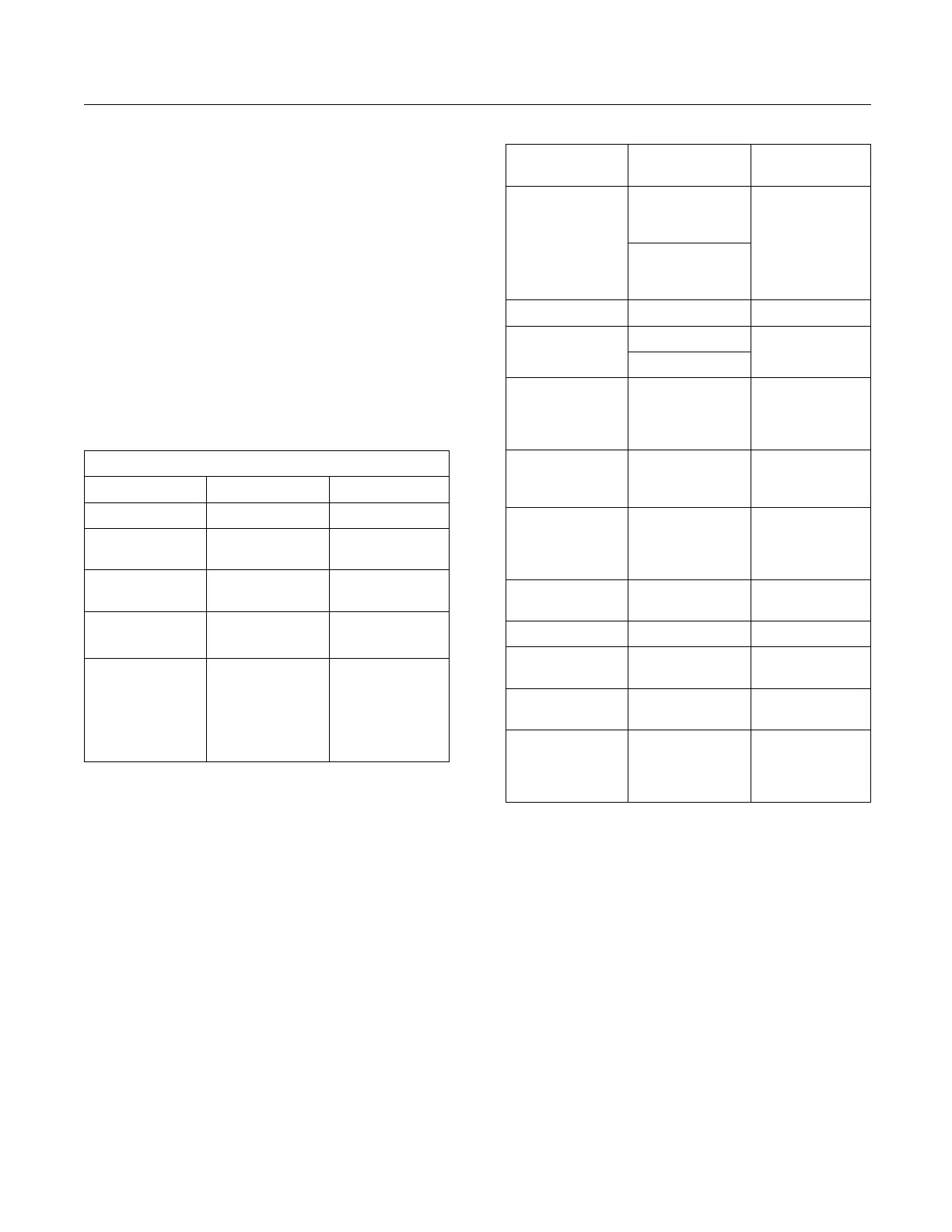

(Tab le 8, contd)

Copper Strip

Corrosion

No. 3 maximum

“D130”

10% at 282 °C

(540 °F)

maximum

Distillation

90% at 360 °C

(680 °F)

maximum

“D86”

Flash Point legal limit “D93”

30 minimum

API Gravity

45 maximum

“D287”

Pour Point

6°C(10°F)

minimum

below ambient

temperature

“D97”

Sulfur

(1)

0.2% maximu

m

“D3605”

or

“D1552”

Kinematic

Viscosity

(2)

2.0 cSt minimum

and 4.5 cSt

maximum at

40 °C (104 °F)

“D445”

Water and

Sediment

0.1% maximum

“D1796”

Water

0.1% maxi

mum

“D1744”

Sediment

0.05% maximum

(weight)

“D473”

Gum and Resins

(3)

10 mg per 100

mL maximum

“D381”

Lubricity

(4)

0.38 mm

(0.015 i

nch)

maximum at

25 °C (77 °F)

“D6079”

(1)

Perkins fuel s ystem s and engine components can operate

on high sulfur fuels. Fuel sulfur levels affect exhaust

emissions. H igh sulfur fuels also increase the potential

for corrosion of internal components. Fuel sulfur levels

above 0.5 percent may significantly shorten the oil change

interval. For additional information, see this publication, “Fluid

Recommendations/Engine Oil” topic (Maintenance Section).

(2)

The values of the fuel v iscosity are the values as the fuel

is delivered to the fuel injection pumps. If a fuel with a low

viscosity is used, cooling of the fuel may be required to

maintain a 1.4 cSt viscosity at the f uel injection pum p. Fuels

with a high viscosity might require fuel heaters in order to bring

down the visc o sity to a 20 cS t viscosit y.

(3)

Follow the test conditions and procedures for gasoline (motor).

(4)

The lubricity of a fuel is a concern with low sulfur fuel. To

determine the lubricity of the fuel, use either the “AS TM D6078

Scuffing Load Wear Test (SBOCLE )” or the “ASTM D6079 High

Frequency Reciprocating Rig (HFRR)” test. If the lubricity of a

fuel does not meet the minimum requirements, consult your

fuel supplier. Do not treat the fuel without consulting the fuel

supplier. Som e additives are not c ompatible. These additives

can cause problems in the fuel system.

Loading...

Loading...