PAL-AT Installation Manual

31

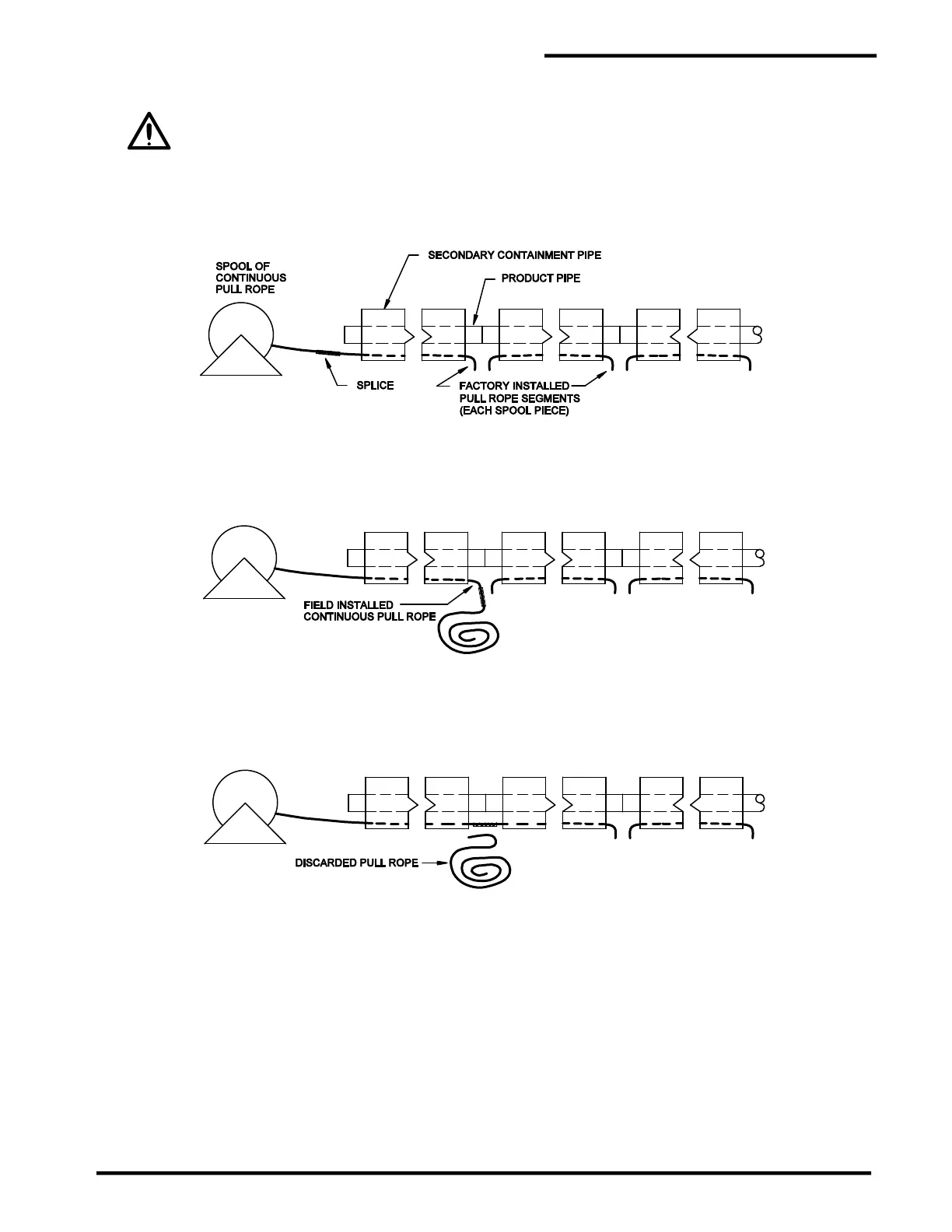

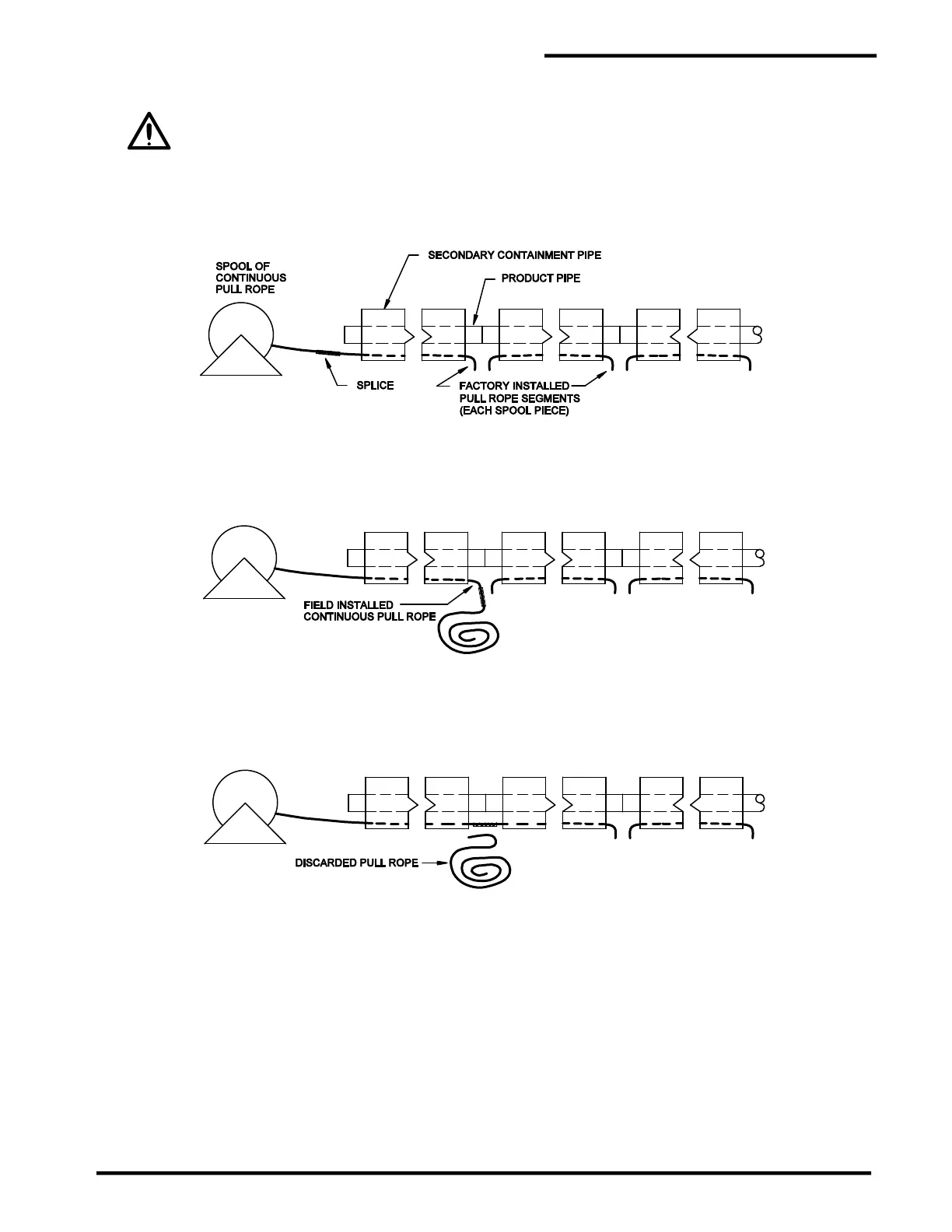

5. Caution all workers involved in the pipe installation that the factory installed pull rope should

never be “temporarily” removed with the expectation it can be replaced later. Losing the end of

the pull rope and allowing it to fall back inside the secondary containment must be avoided. Special

care must be taken at risers where the weight of the rope, in the vertical section of the pipe, tends to

pull the rope into the secondary containment.

Step A Splice the continuous pull rope to the factory installed pull rope. Follow splicing procedures

contained in the “Cable Splices” section.

Step B Go to the first uncompleted secondary containment field joint and pull the continuous pull rope into

the first section of piping until the splice exits the field joint.

Step C Break the splice on the factory installed pull rope and discard the pull rope. Splice the continuous

pull rope to the next section of factory pull rope, and pull the continuous pull rope into the next pipe

Step D Return to the first field joint. If the product pipes are insulated, apply insulation material. To

prevent the continuous pull rope from being damaged during joining of the secondary containment,

it must be held off the bottom of the containment. Attach the pull rope temporarily to the carrier

pipe (insulation) by looping a piece of 22 gauge steel wire around the carrier pipe (insulation) and

twisting the ends together to form a hook around the pull rope.

Loading...

Loading...