PAL-AT Installation Manual

9

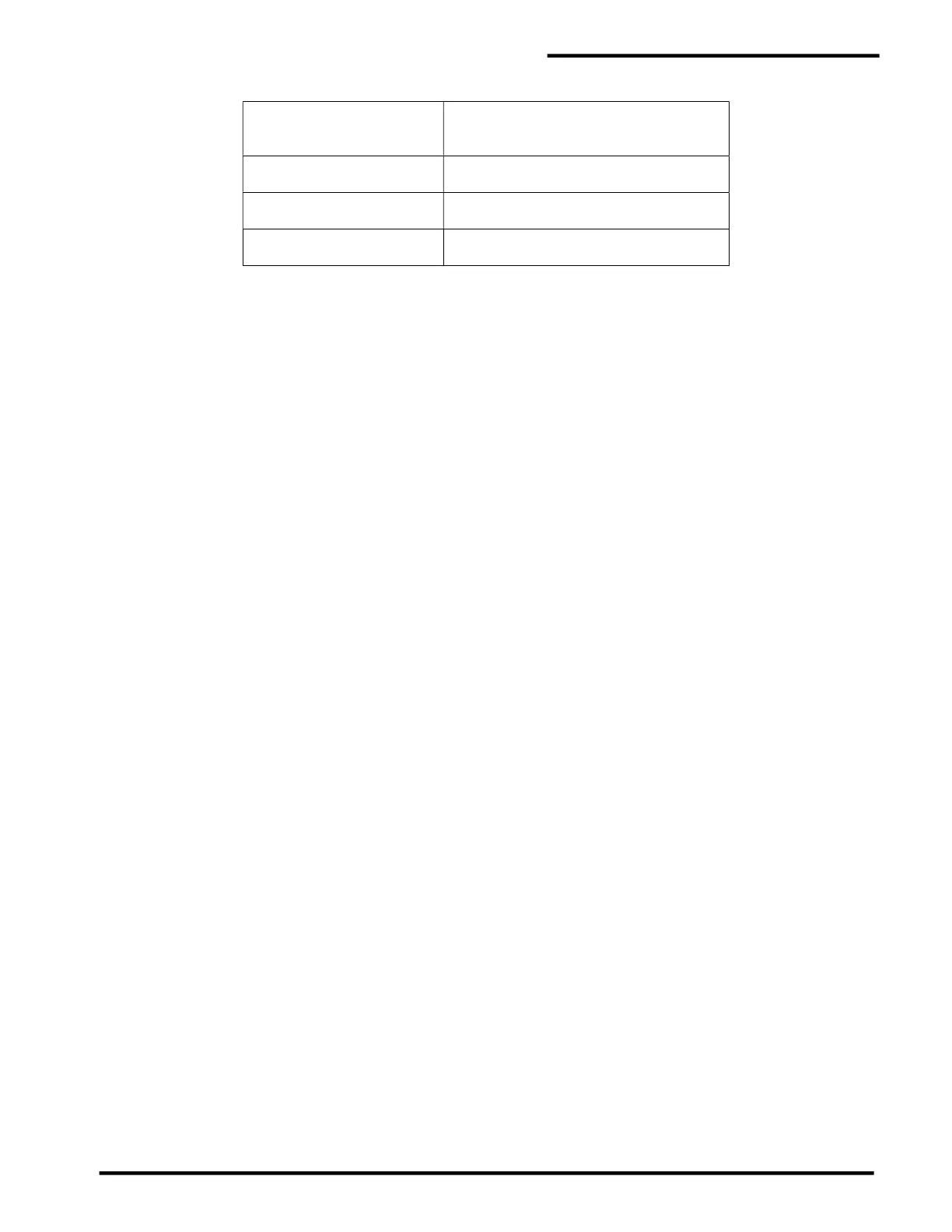

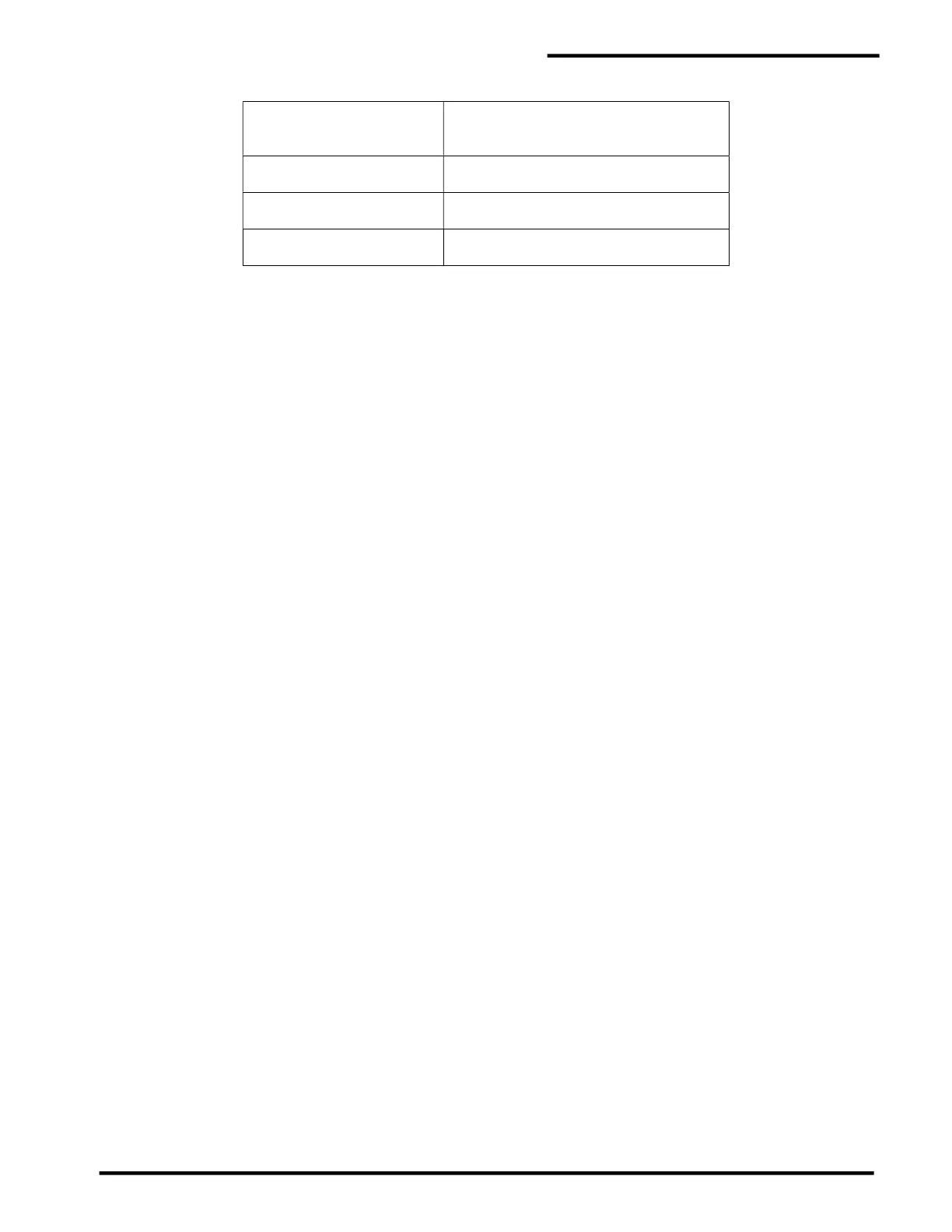

Maximum No. of

Cable Connectors

in Enclosure

Enclosure Dimensions

1

6" x 6" x 4"

[150 mm x 150 mm x 100 mm]

2

8" x 6" x 4"

[200 mm x 150 mm x 100 mm]

4

10" x 8" x 4"

[250 mm x 200 mm x 100 mm]

8. Watertight cord grips

9. Shrink tubing for cable connectors

10. Non-corrosive RTV adhesive/sealant for cable connectors

1.5 Materials and Equipment Normally Supplied by Installing Contractor

Each system may require the installing contractor to supply the following items:

1. Pull rope, 1/8" [3 mm] diameter, 7 strands, steel wire rope aircraft cable. For installation of cable in

fiberglass or other plastic piping systems, use plastic coated (non-vinyl) wire rope. Provide pull rope

in quantities equal to 120% of system length. (Included with Perma-Pipe piping systems)

2. Cable spool rack or stand

3. PVC electrical tape

4. Miscellaneous pipe nipples, unions, and fittings, as required to provide watertight jumper cable

connections to sensor cable.

5. 1" rigid or liquid-tight flexible electrical conduit, as required, for installation of jumper cable within

manholes, pits, and buildings. Use 1" conduit hub, OZ Gedney CH-100, or equal, connection to

junction boxes.

6. Electrical conduit, junction boxes, and wiring, as required.

7. Ohmmeter for testing jumper cables and sensor cables.

8. 1000-volt megger for testing ATP sensor cable.

9. Hole saw or knockout punch.

10. Construction adhesive mastic for attachment of cable mounts to unsealed concrete surfaces

11. Hot air gun for shrink tube application on cable connector assemblies

Loading...

Loading...