PAL-AT Installation Manual

79

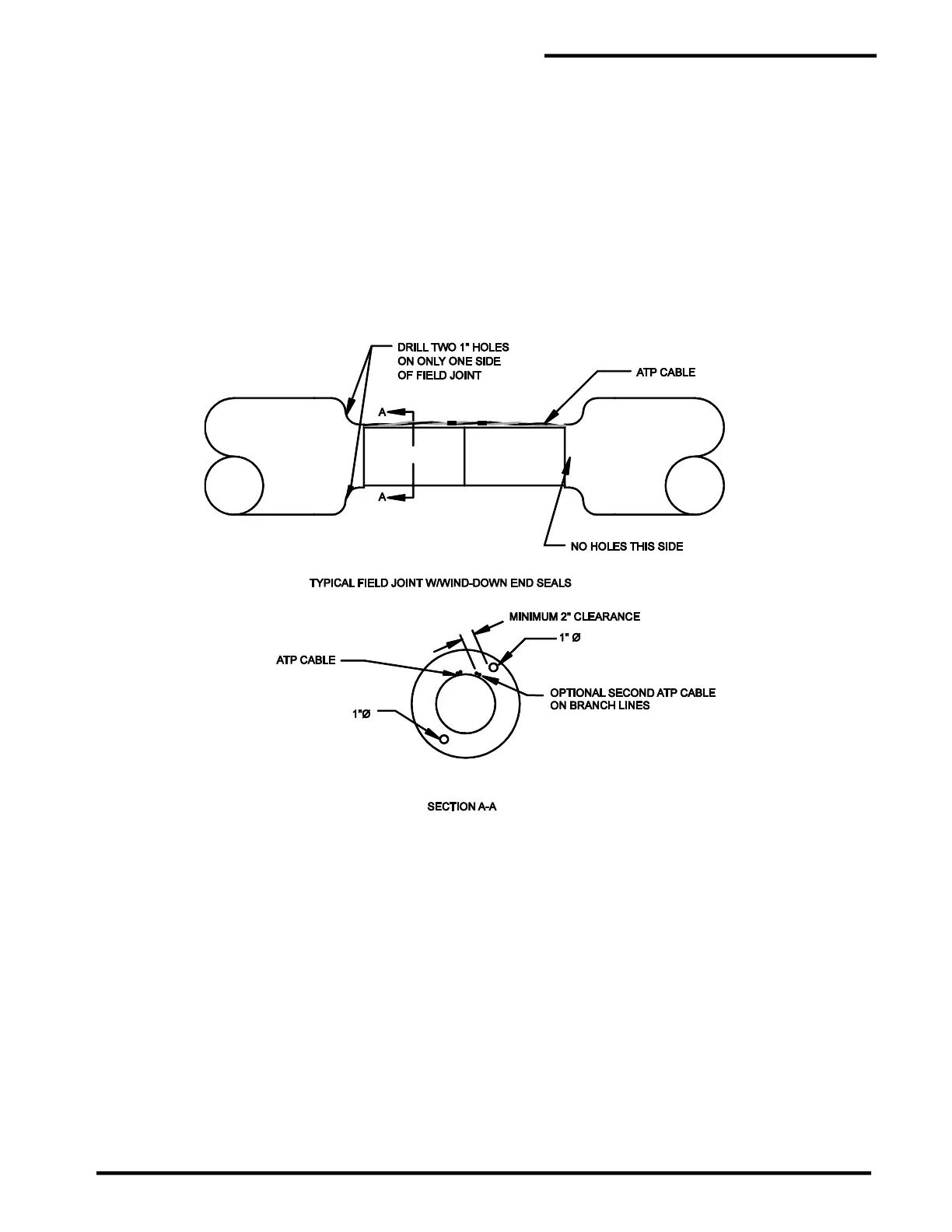

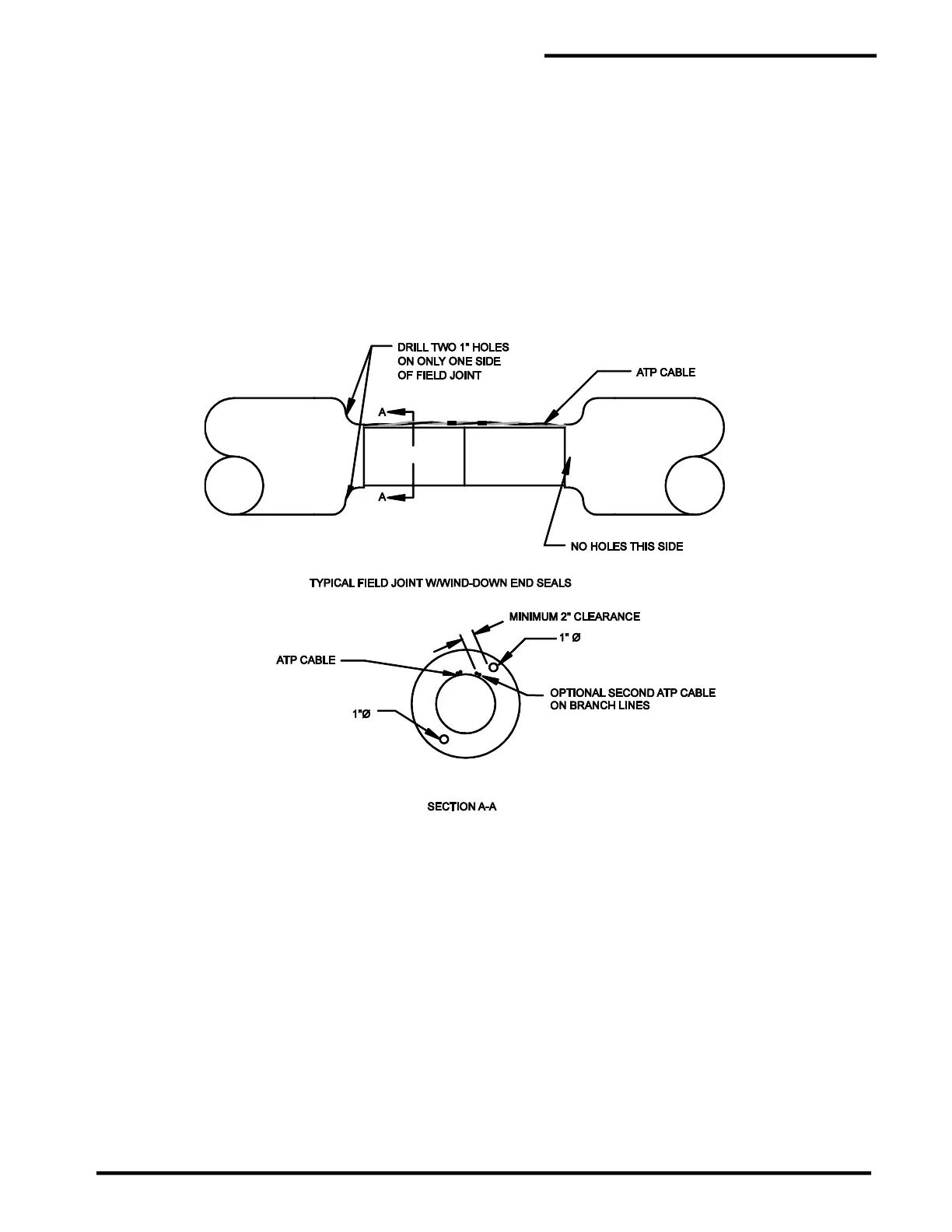

10.10 Requirements for Field Joints with Wind-Down End Seals

This procedure only applies to field joints where two pipes with wind-down end seals are joined together.

It should not be performed until immediately before the insulation and shrink sleeve are applied to

seal the field joint.

1. Drill two 1” diameter holes through the jacket in the wind-down portion of only one of the end

seals. It does not matter which of the two end seals is drilled (see Figure 10-5).

2. The holes should be spaced at least 2” away from the ATP cable to prevent accidental

damage to the cable during drilling.

3. One hole should be located in the top half on the end seal and the other approximately opposite it

in the bottom half.

4. Be careful not to damage the ATP cable or pipe when drilling the holes.

5. Test the ATP wires for continuity and insulation as described above after drilling the holes.

6. Proceed with the normal field joint closing procedure.

Figure 10-5

Wind-Down End Seal Modification

Loading...

Loading...