PAL-AT Installation Manual

36

6 Installation of Direct Buried Sensor Cable

6.1 General

The following instructions and precautions are very important for the successful installation and operation

of the PAL-AT system with direct buried sensor cable. These instructions do not cover every possible

situation, but are intended as guidelines for the majority of applications. Remember, the sensor cable is a

sensitive electrical cable and should not be crushed, stretched, kinked, cut or damaged. If you have any

questions regarding the installation of the direct buried cables, contact PermAlert. Failure to follow these

instructions may result in damage to the cables or its jacket and prevent or limit operation of the PAL-AT

system.

1. TFH and TFH-Gold cables are constructed of materials that detect hydrocarbon liquids, but ignore the

presence of water. TFH cable has an outer jacket to protect the nickel-plated, copper braid wire. TFH-

Gold cable does not have an outer jacket, but uses polymer-coated braid wire that is corrosion

resistant.

2. These unique sensor cables can be installed in wet soil environments while monitoring for the leakage

of hydrocarbon liquids. This feature permits direct burial of TFH/TFH-Gold, in 1½” or 2” “screened” or

slotted PVC pipe, for the monitoring of underground single wall piping and tanks. The maximum burial

depth of TFH/TFH-Gold cables is 20' [6 m]. This limitation is due to the fact the cable materials repel

water to a maximum pressure of 8.7 psi [0.6 bar]. If the cable jacket (TFH) or cable core (TFH-Gold)

is damaged, water may enter the cable and prevent or limit the operation of the PAL-AT system.

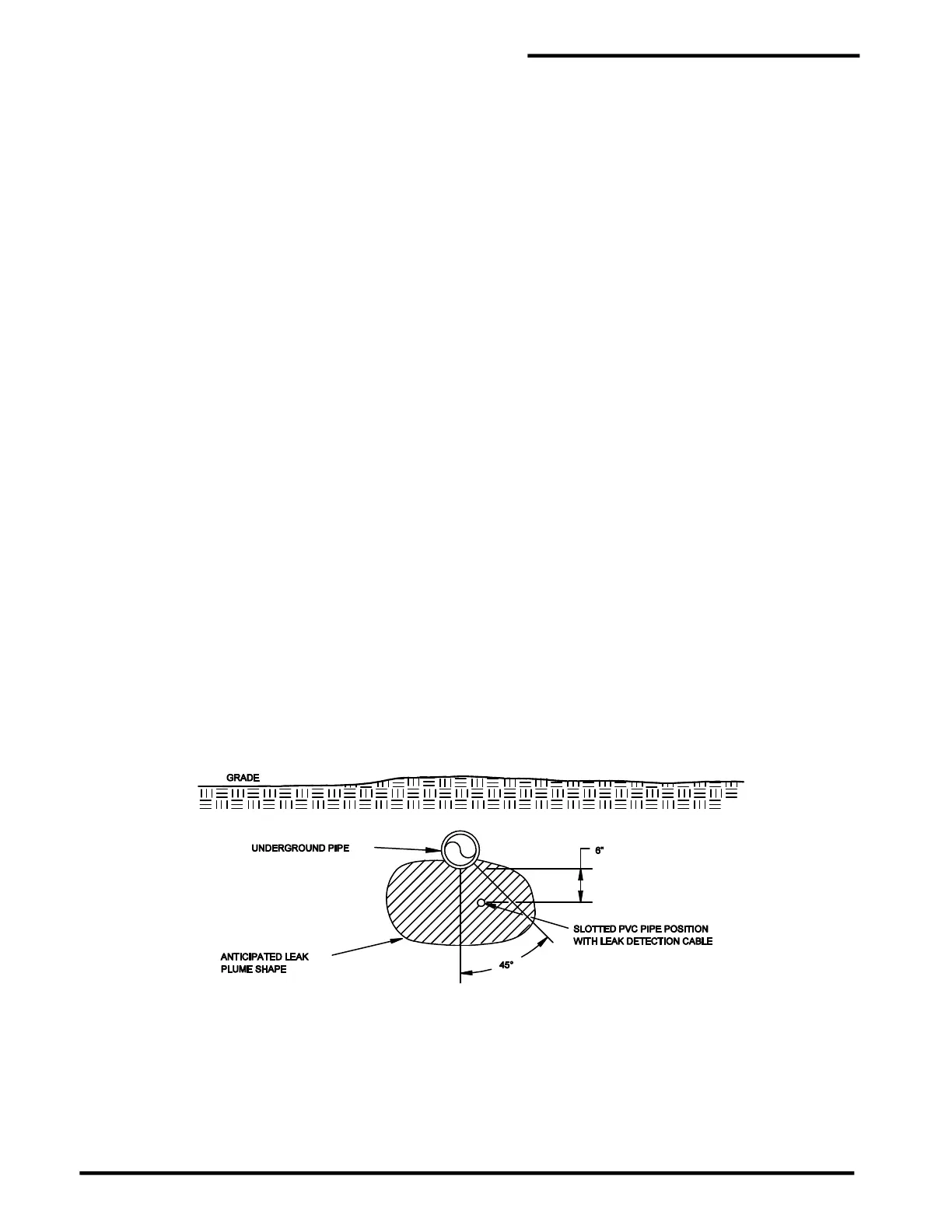

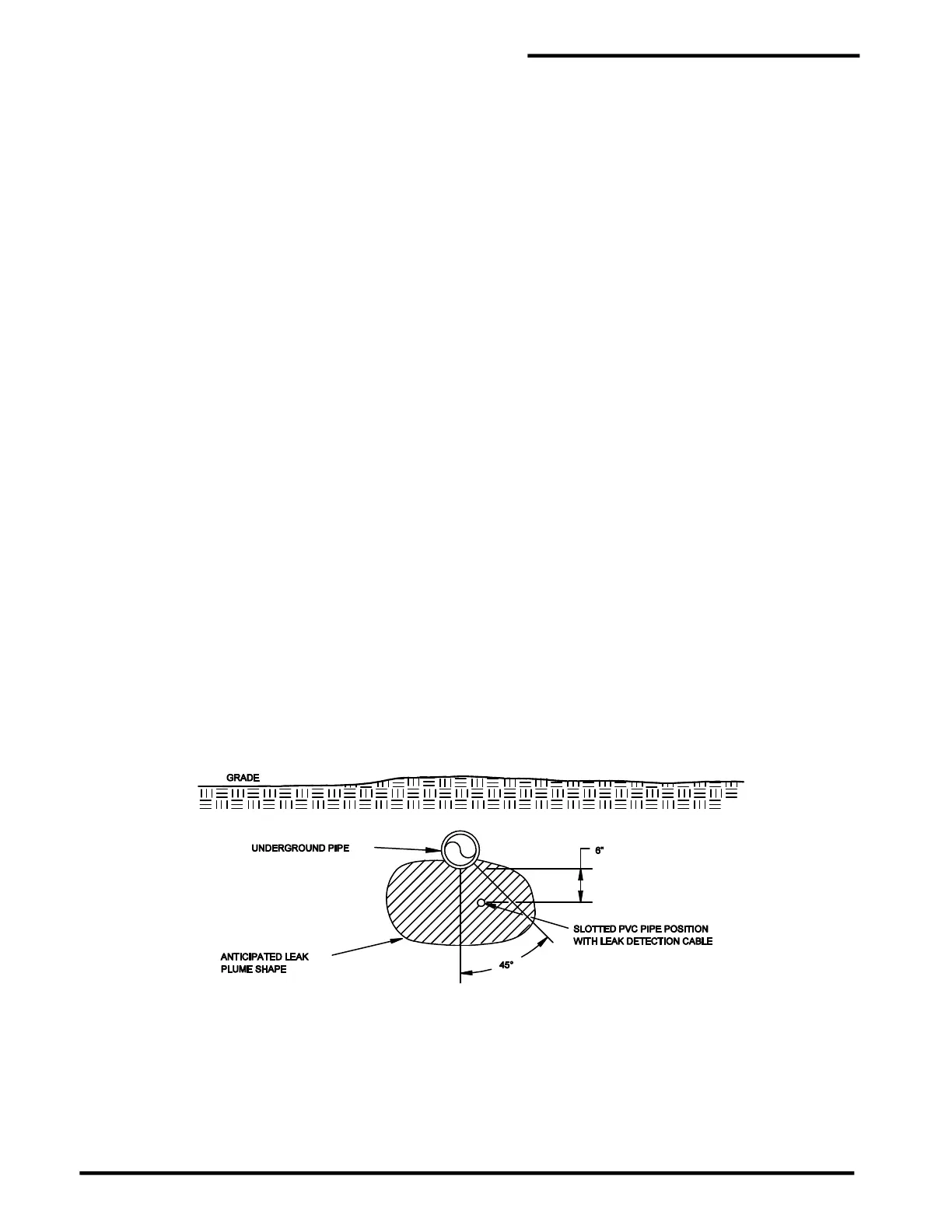

3. The location of the slotted pipe and hydrocarbon detection cable is determined by several variables.

These variables include soil type, backfill material, product in the pipeline, water table, pipeline

pressure and leak rate. Another consideration is if the installation is new or a retrofit of an existing

pipeline.

4. It is recommended to slide a fabric sleeve or sock liner over the slotted PVC pipe to minimize soil

entering and possibly blocking the pipe after an extended time. A 3” sleeve is typically available in

home improvement stores and other sizes are available at industrial sources.

5. The sensor cables must be located where the hydrocarbon liquids will collect and allow detection. For

some applications, the use of a closed synthetic liner, installed in the pipe trench, may be considered

to facilitate the collection of hydrocarbon liquid for detection and reduce soil contamination. Normally

one cable located in a slotted pipe adjacent to an underground pipe will provide satisfactory results.

The slotted pipe may be located under the service pipe for a new installation. If the system is installed

with an existing pipeline, the slotted pipe can be installed a few inches to the side of the pipeline to

minimize the excavation cost.

6. If buried TFH/TFH-Gold is submerged in water and the water freezes, the resulting compression of the

cable may be detected as a leak and cause an alarm. This effect should be considered when

determining the placement of the cable to reduce false alarms. It does not damage the cable.

7. The recommended minimum bend radius for all sensor and jumper cables is 1.5” [38mm].

Loading...

Loading...