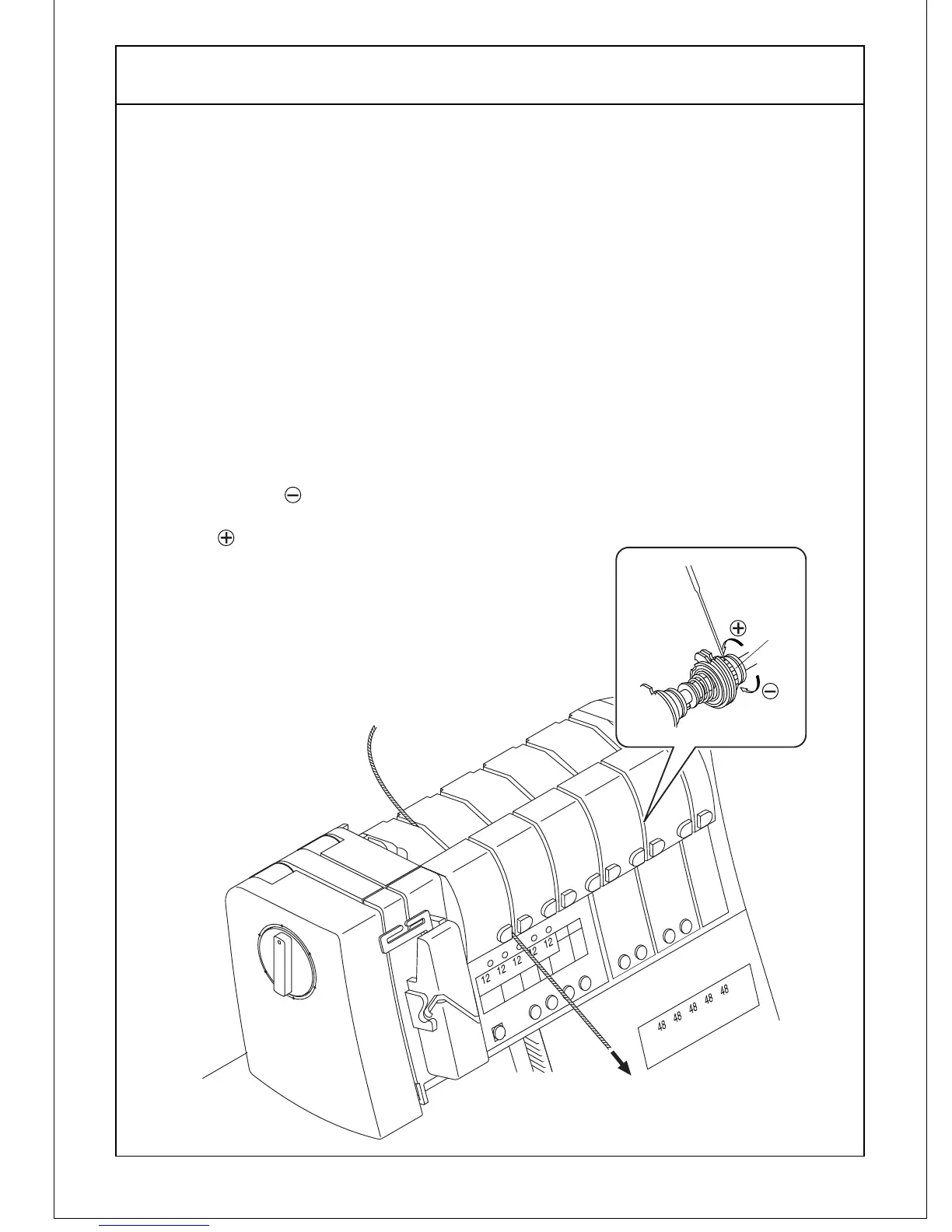

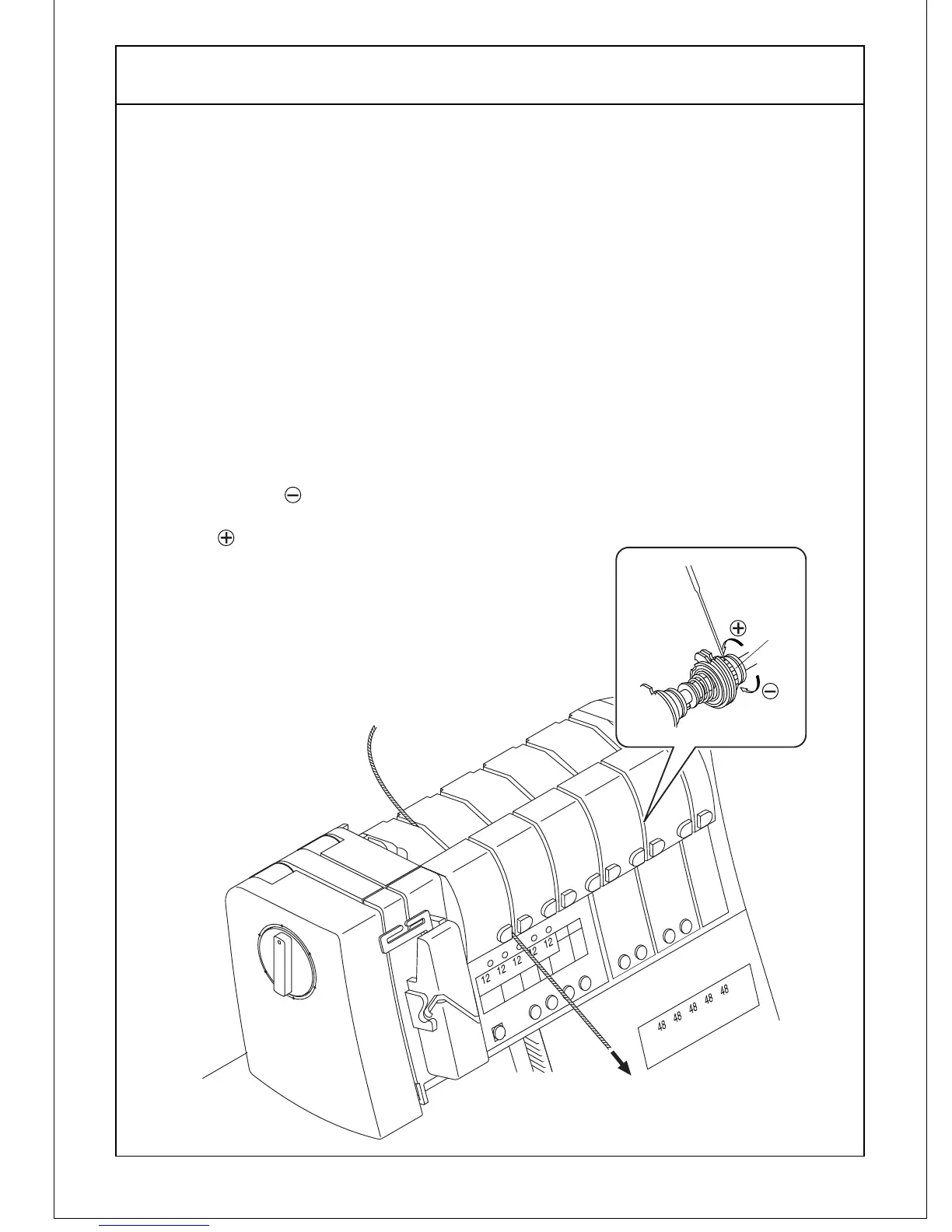

TEST PROGRAM-THREAD TENSION SETTING-DIAL TENSION

FINE TUNING

E1

e

d

Test program for minimum dial tension (step 4 in page D1) and maximum

dial tension (step 5 in page D2 ).

The following manners are used for the setting of step motors (dial tensions).

a) Step 4

The step motors will rotate to its minimum position. Check the tension value by pulling

a polyeter thread #60/3 in the direction of "e" as drawing below. Make sure that each

tension is set at 5 to 15 gr.

b) Step 5

The step motors will rotate to its maximum position. Check the tension value in the same

manner as mentioned in the step 4. Make sure that each tension is set at 40 to 50 gr.

c) If not, adjust the tension(s) with the fine tuning dial "d".

Note: The fine tuning can be executed without removing the covers by using a point of

needle, as shown in the drawing below.

d) Fine tuning with dial "d"may be executed as follows:

i) If thread tension appeared as strong (stitch becomes tight),dial "d" should turn to the

direction of with the point of needle.

ii) To the contrary, if it appeared as not eough strong,dial "d" should turn to the direction

of with thepoint of needle.

Loading...

Loading...