HEIGHT-CLEARANCE-ANGULAR POSITION OF LOWER LOOPER 7

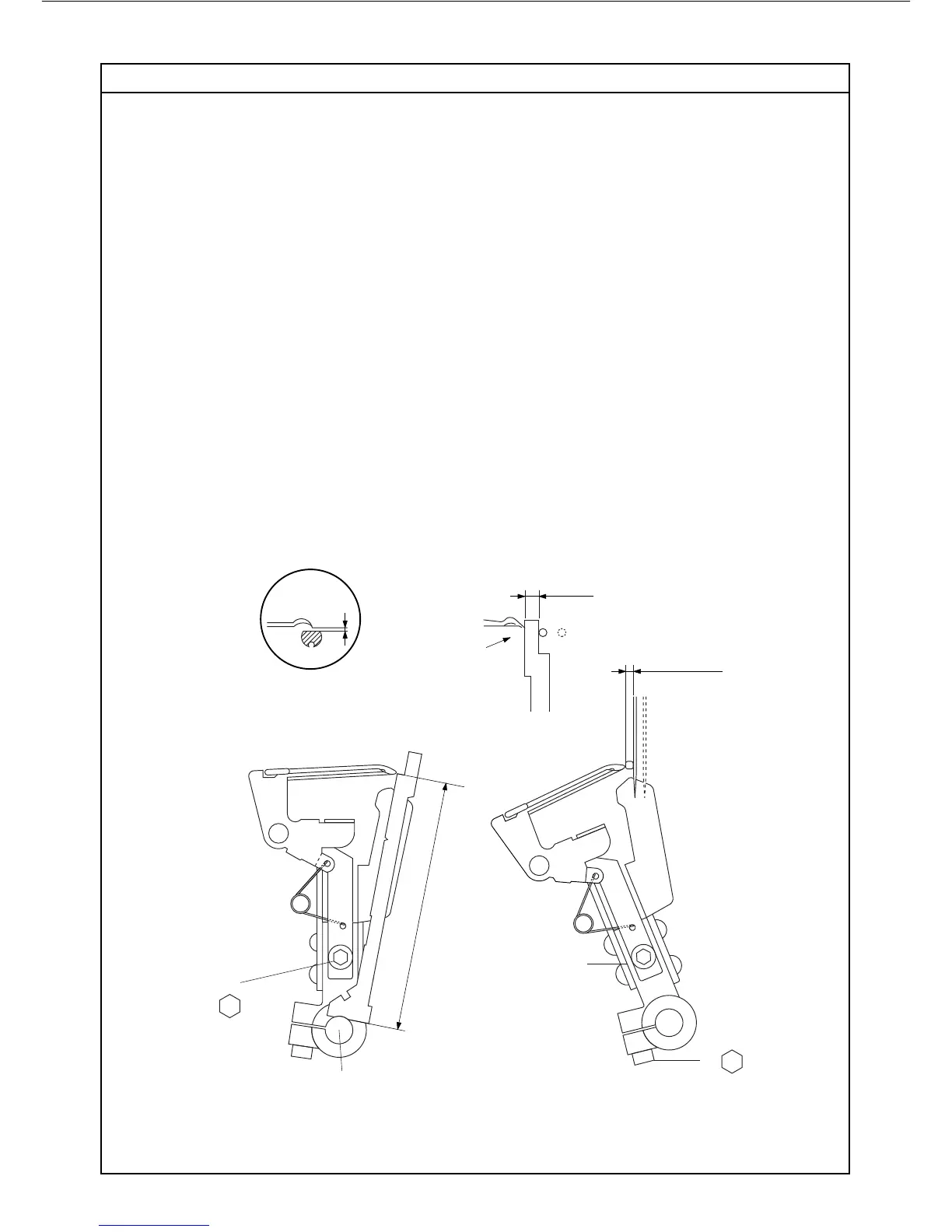

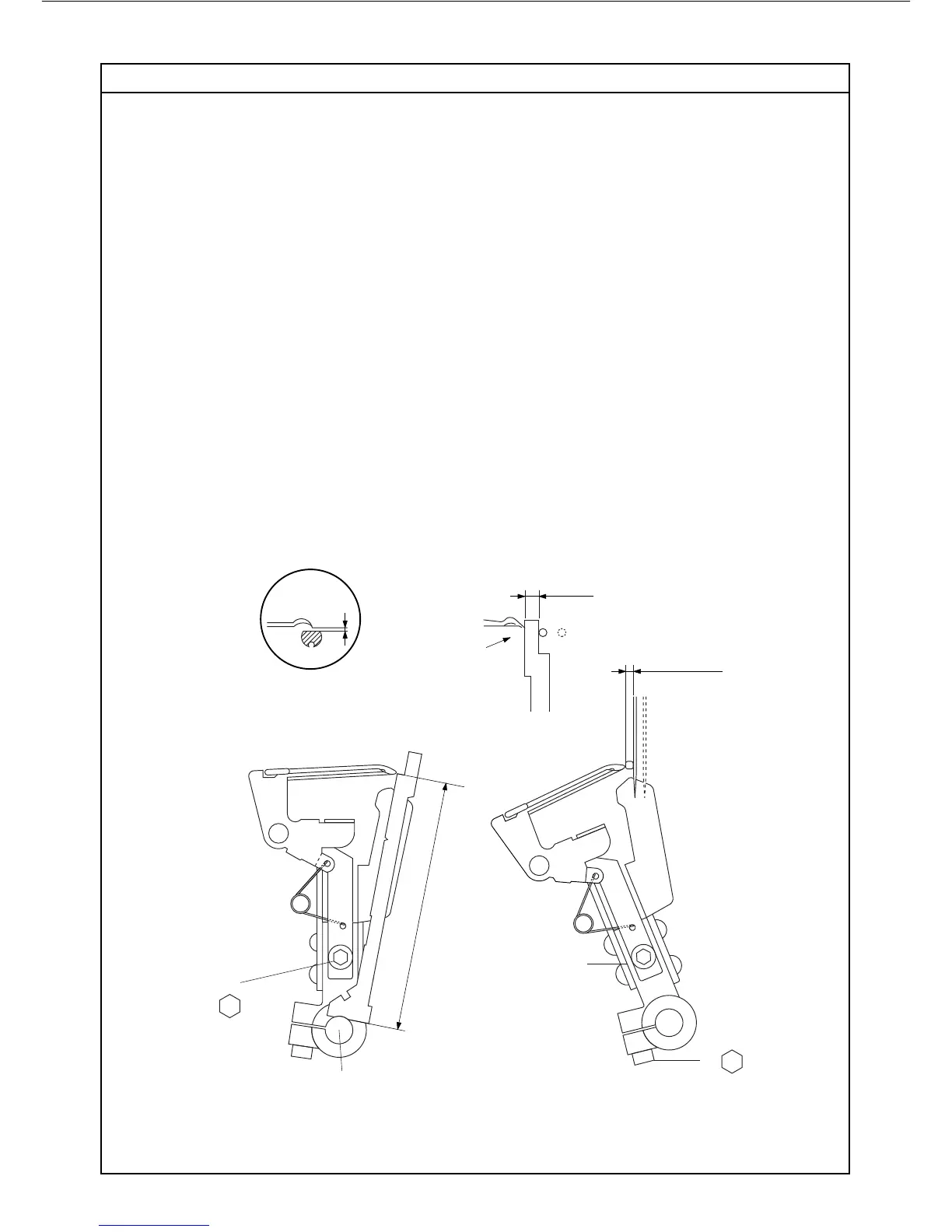

0.05 mm

65mm

2.8~3.1mm

3mm

2mm

b

c

a

x

2.8mm

R1

1. Remove: Mains lead. - Sewing foot

2. Make sure that there is no axial play on looper shaft "x".

3. Loosen screw "a", adjust height of lower looper as shown and tighten screw "a".

4. Adjust clearance of overlock needle guard.

5. Insert a new needle (Nm 90) in R1 and check height and orientation of needle bar.

6. Remove needle plate and machine base.

7. Loosen screw "b" just enough to be able to shift lever "c".

8. Adjust lever "c" axially to obtain a clearance of less than 0.05mm between point of looper

and needle; see below.

9. Turn the handwheel and bring lower looper to its extreme left swing position and adjust

lever "c" angularly to obtain 2.8 to 3.1mm between point of looper and the left side of the

ovelock needle.

10. Recheck clearance and carefully tighten screw "b".

Loading...

Loading...