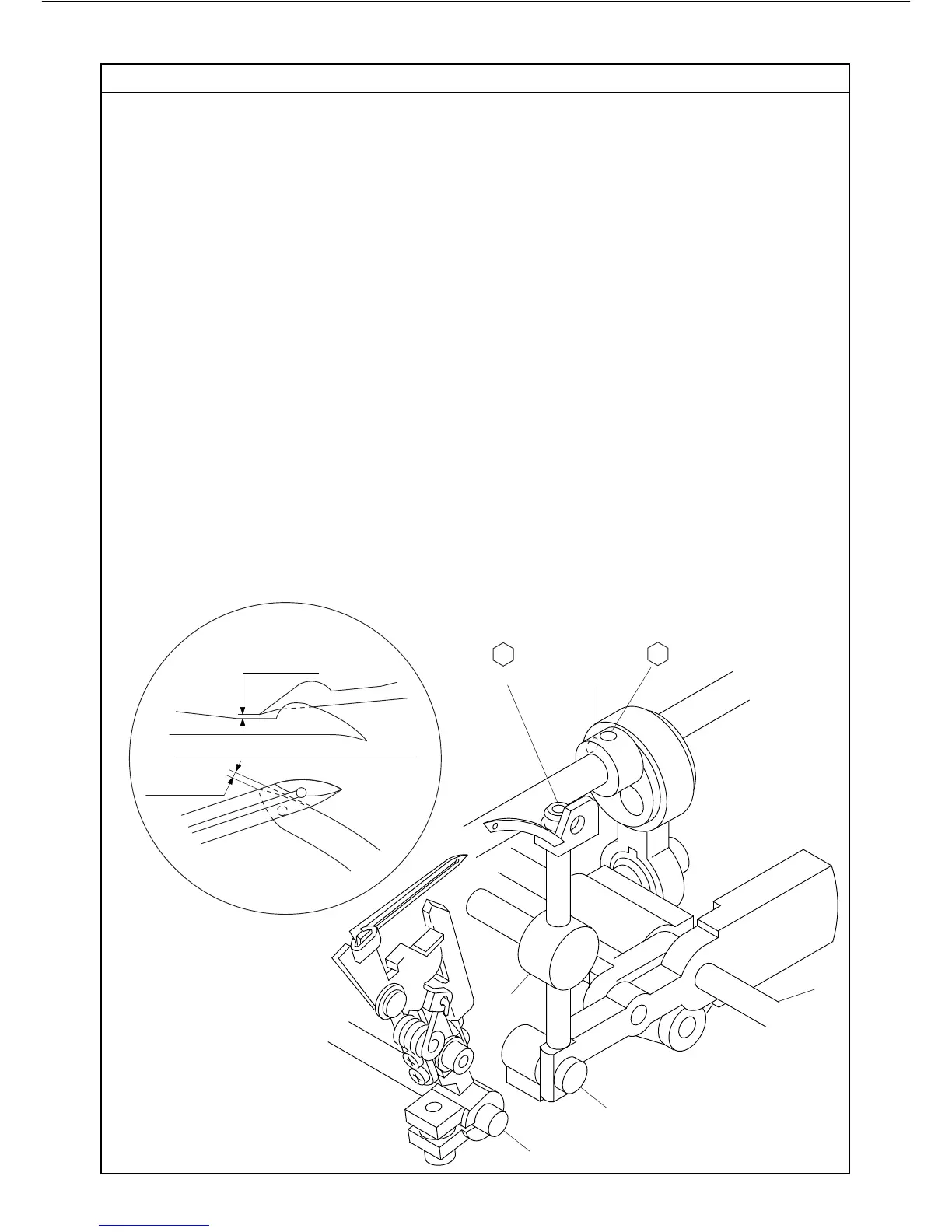

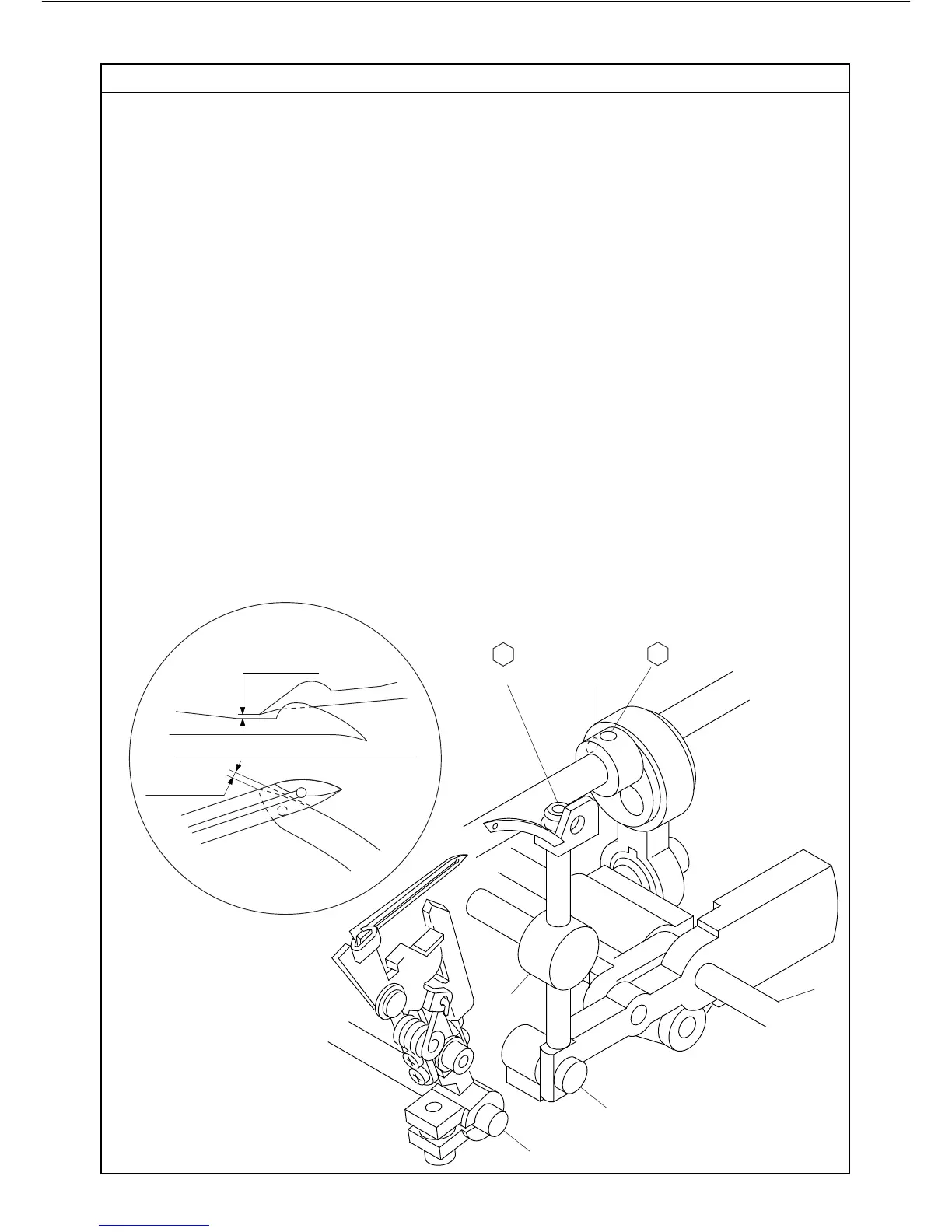

CLEARANCE AND TIMING OF UPPER LOOPER TO LOWER LOOPER 11

0.05~0.2mm

0.5~1.0 mm

A

B

e

2.5mm

2mm

b

c

d

a

f

1. Remove: Mains lead - Sewing foot.

2. Check adjustments:

- Height and orientation of needle bar (see page 6).

- Height - clearnce - angular position of lower looper (see page 7).

- Timing of lower looper (see page 9).

3. Remove machine base.

4. Make sure that there is no axial play, neither on the lower looper shaft "a", the upper

looper shaft "b", nor on the 2 pivoting axles "c" and "d".

5. Clearance: Loosen screw "e" slightly and adjust upper looper to lower looper to obtain a

clearance of 0.1mm between them when they pass each other; see detailed drawing "A".

6. Tighten screw "e" securely and recheck clearance.

7. Timing: Adjust timing of upper looper so that its point passes 0.5 to 1.0mm below the

hump of lower looper; see detailed drawing "B". If necessary, loosen both screws of upper

looper eccentric "f" (No. 4 on page 4, then, by means of one screw, hold eccentric "f" and

turn slightly handwheel, either forward to advance or backward to retard, upper looper in

relation to lower looper.

8. Tighten both screw of eccentric "f".

9. Refit machine base.

Loading...

Loading...