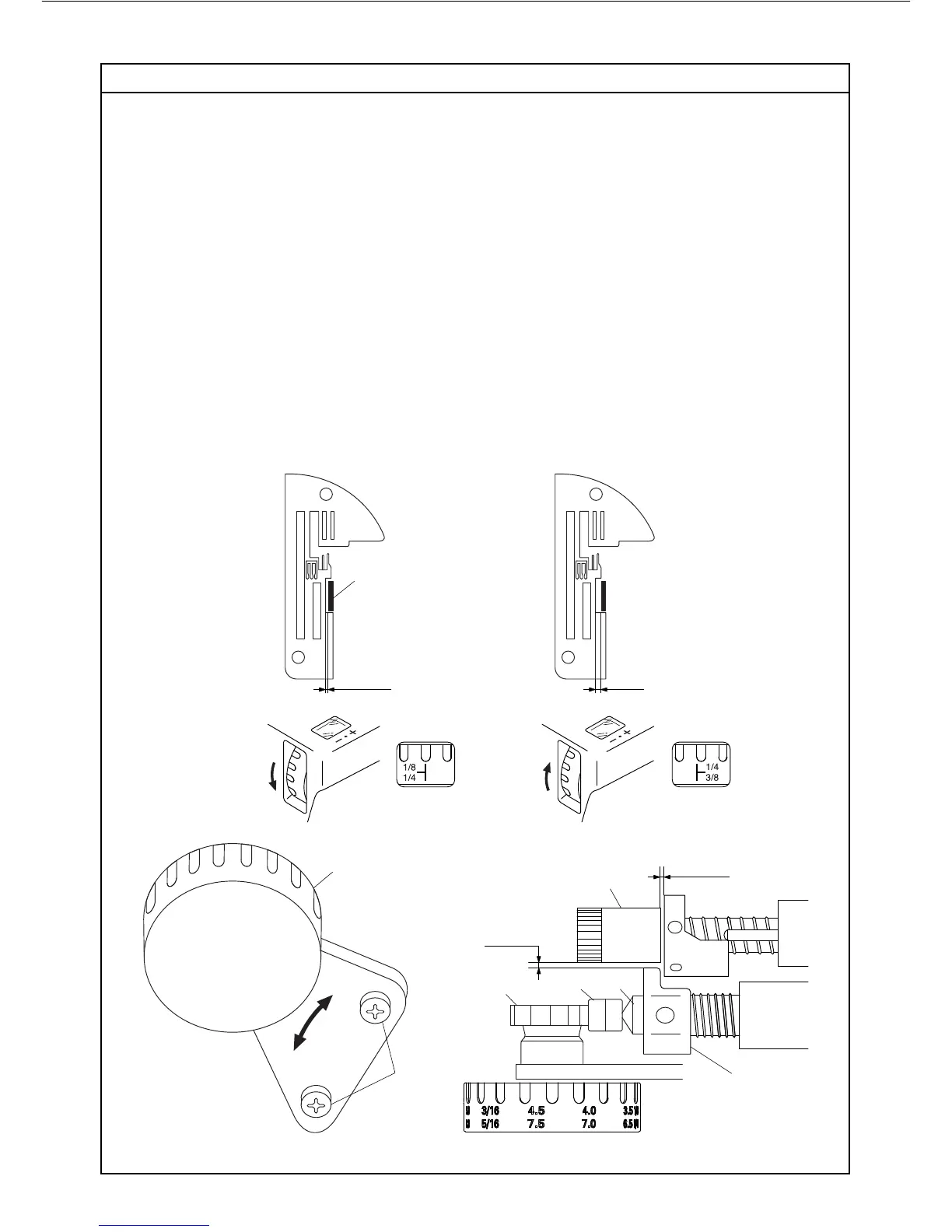

POSITION OF FIXED CUTTER AND CUTTING WIDTH DIAL SETTING 18

c

a

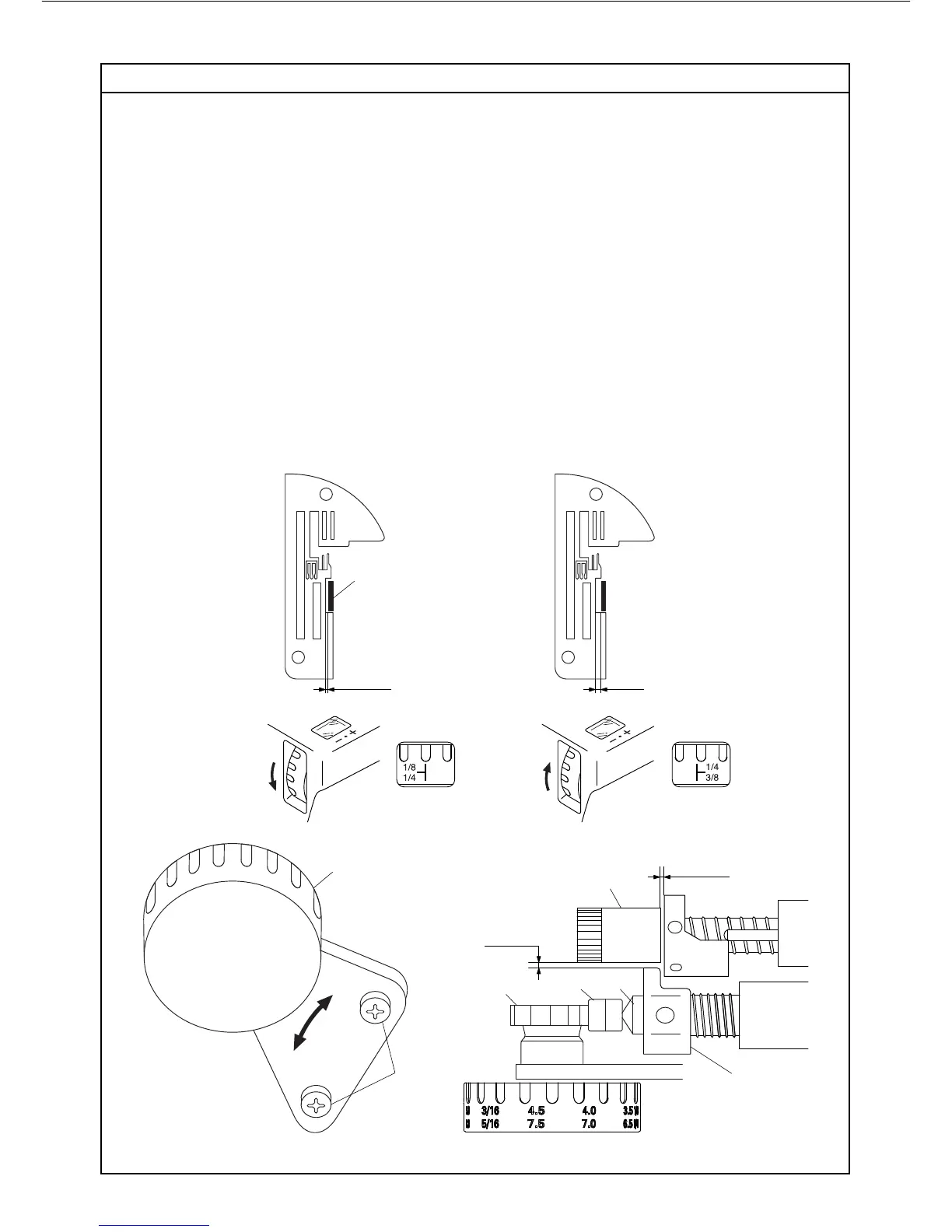

0.2~0.3mm

b

MAX

0.1~0.2mm

g

0.1~0.2mm

h

f

e

d

1. Remove: Mains lead - Sewing foot - Needles.

2. Disengage moving cutter.

3. Basic position: Turn dial "a" to bring indicator to position mark "1/4~1/8" and check if

clearance of 0.2~0.3mm is obtained between fixed blade "b" and needle plate edge.

4. Make sure that there is no play between cutting width cam unit "d", lever "e" and shaft

"f".

5. If necessary, loosen screws "c".

6. Push unit dial to the right to obtain a clearance of 0.2~0.3mm.

7. Tighten screws "c" and check the clearance between fixed blade and needle plate edge.

Note: Re-engage moving cutter and make sure that the moving blade release knob "g" is not

touching the shaft support "h" (the gap between "g" and "h" is 0.1~0.2mm).

Loading...

Loading...