ENG

Operating Manual | Attachment and Installation Cooling Units | Multi Controller (MC) – 400 / 460 V, 3~ | 086100124 58/76

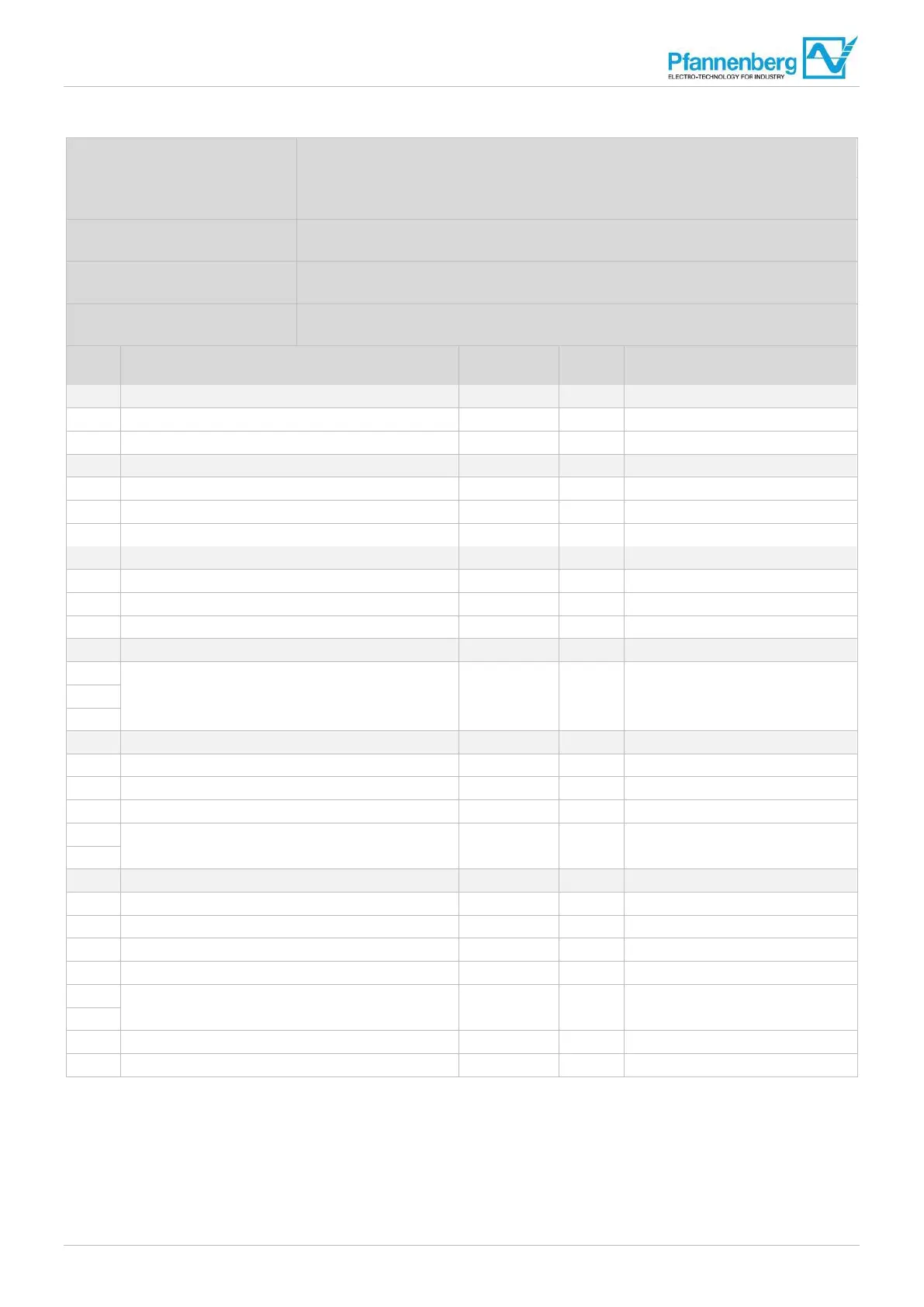

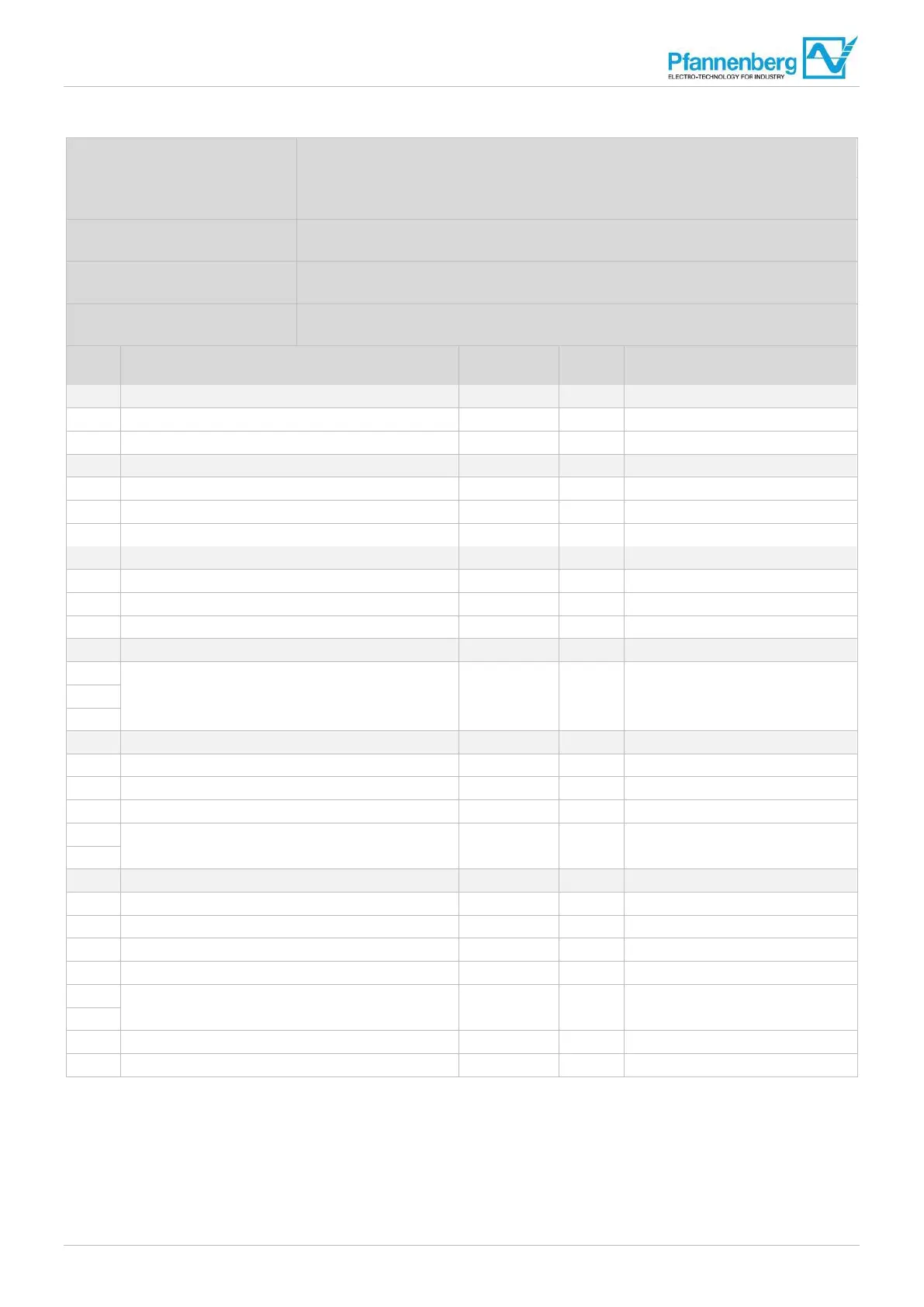

6.3 Maintenance schedule

Maintenance interval:

Perform every twelve months. Every two to six months, in ambient air containing oil and

dust.

Type:

______________________________________________________________________

Serial number:

______________________________________________________________________

Date of maintenance:

______________________________________________________________________

Executing specialist (name):

______________________________________________________________________

Unit area designation /

necessary maintenance work

Visual

To do Result

Aggregate prior to maintenance

1.1 General visual inspection of the aggregate

1.2 Inspection for corrosion damage

2.1 Check refrigerant carrying parts for oil traces

2.2 Check refrigerant carrying parts for leaks

2.3 Check electrical connections for damage

3.1 Check pipe assembly for deposits

3.2 Inspection for general corrosion damage

3.3 Check, clean and align blades*

4 Evaporator/heat exchanger

Check pipe assembly for deposits

4.2 Inspection for general corrosion damage

4.3 Check, clean and align blades*

5 Condenser fan (external)

5.1 Check holder for loose parts

5.2 Check electrical connections for damages

5.3 Check motor bearing for noise

5.4 Check drive for signs of overheating

5.5 Clean fan*

Evaporator fan (internal)

6.1 Check holder for loose parts

6.2 Check electrical connections for damages

6.3 Check motor bearing for noise

6.4 Check drive for signs of overheating

6.5 Clean fan*

7.1 Change filter mat*

7.2 Clean filter mat*

Tab. 17: Cooling unit maintenance schedule

* Maintenance intervals more frequent, depending on the level of contamination.

Loading...

Loading...