EN – 38

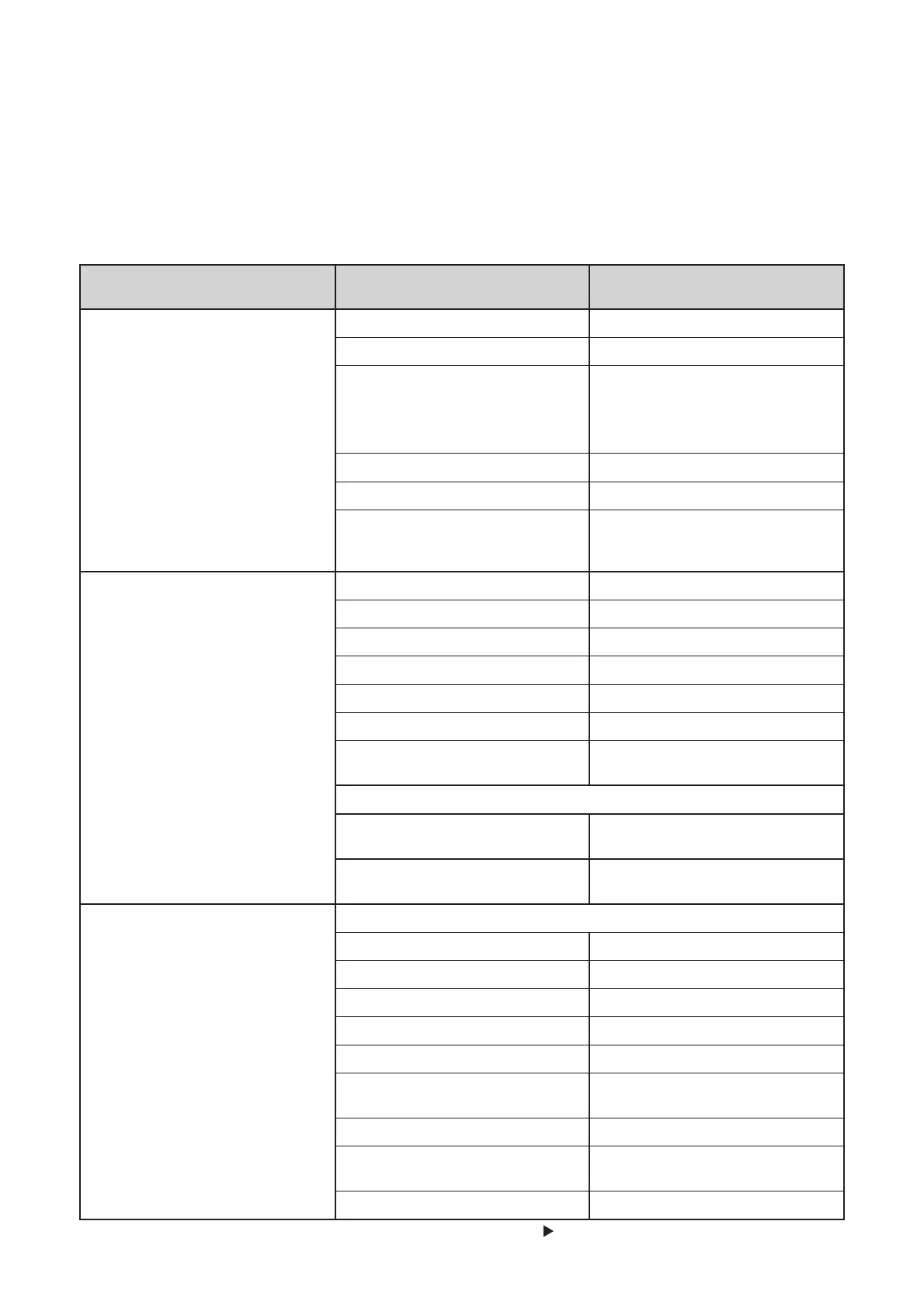

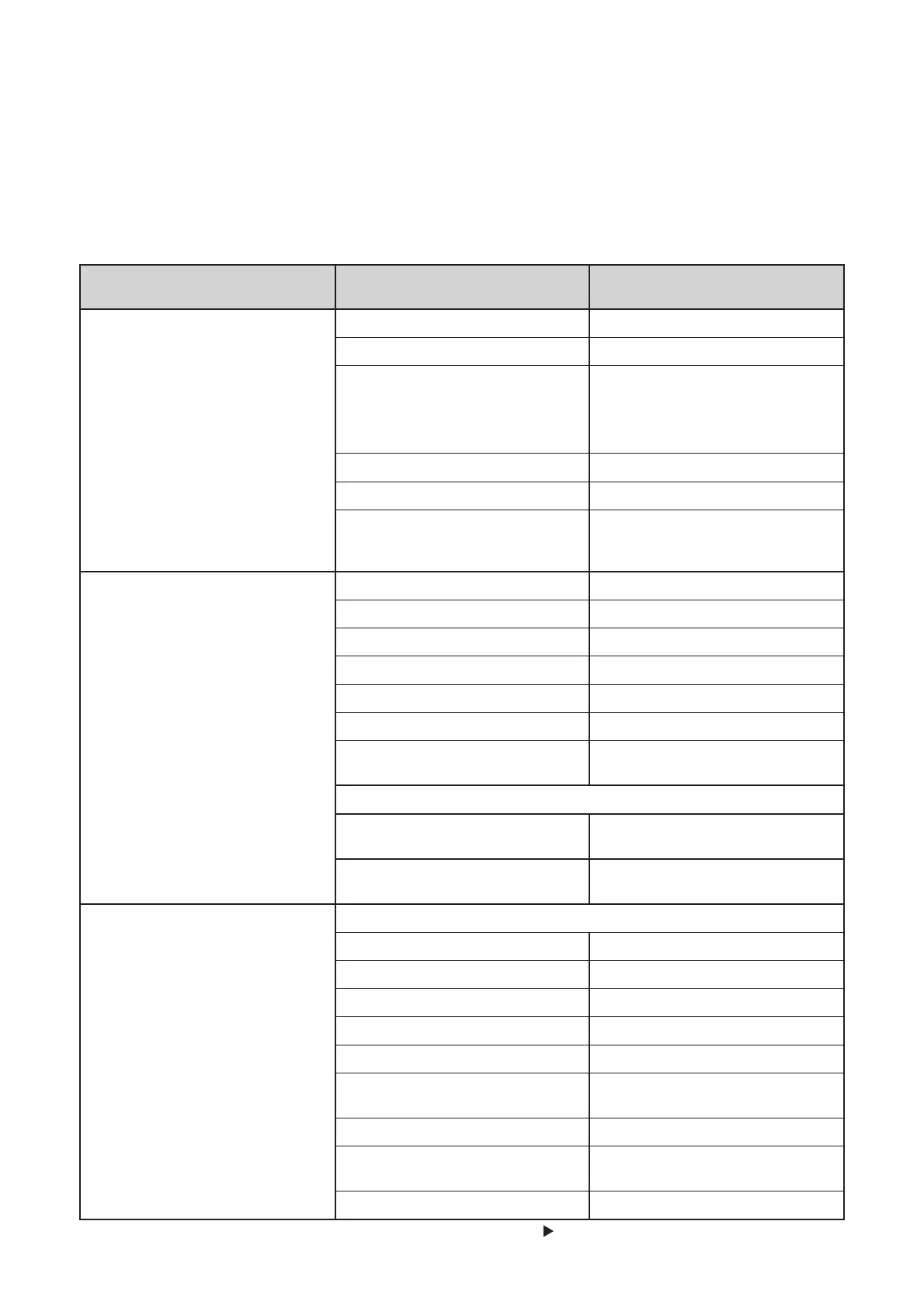

Incidents Causes Corrective actions

The pump is not running Incorrect motor power supply.• Check the power supply.

Temperature too low.• Reheat the pump and its oil.

Gumming of seals after prolonged

storage.

• Disassemble the motor and try to turn

the fan manually.

Disassemble, clean the pump, replace

seals, reassemble.

Oil contaminated after pumping.• Drain, flush and refill with clean oil.

Motor coupling damaged.• Replace by disassembling the motor.

Pump seized, due to a stopping after

pumping in difficult conditions (no

draining or flushing).

• Disassemble, clean, hone the scratched

metal parts (replace them if necessary)

and reassemble.

The pump does not start Oil cold.• Warm pump.

Insufficient oil in the oil case.• Fill up to the level.

Oil contaminated.• Drain, flush and refill with clean oil.

Oil pump inlet partially blocked.• Drain, and clean the oil pump inlet duct.

Lubrication holes blocked.• Disassemble and clean.

Vane of oil pump damaged.• Replace it.

Incorrect anti-suckback system

assembly.

• Repeat the assembly and the setting.

Oil pressure sensor

It indicates a too low or too high

pressure.

Clear the line or check the manometer/

plug tightness.

It continues to indicate a too low or

too high pressure.

Disassemble, clean and reassemble using

maintenance kit.

The vacuum pump does not produce

a vacuum

Ultimate pressure obtained: a few mbar/Torr

Direction of motor rotation incorrect.• Rewire.

Insufficient motor power.• Check the power supply.

Inlet filter blocked.• Clean the inlet filter.

Insufficient oil in the oil case.• Add oil.

Oil cold, oil pump inlet blocked.• Warm, disassemble, clean.

Oil contaminated.• Drain, flush and start again with clean

oil.

Oil pump inlet partially blocked.• Drain and clean the oil pump inlet duct.

One of the LP safety valves is

damaged.

• Replace the LP safety valve.

Part forgotten in reassembly.• Repeat the reassembly.

Troubleshooting and corrective actions

All series C1 C2 C1 and C2

Loading...

Loading...