EN – 39

ENMaintenance

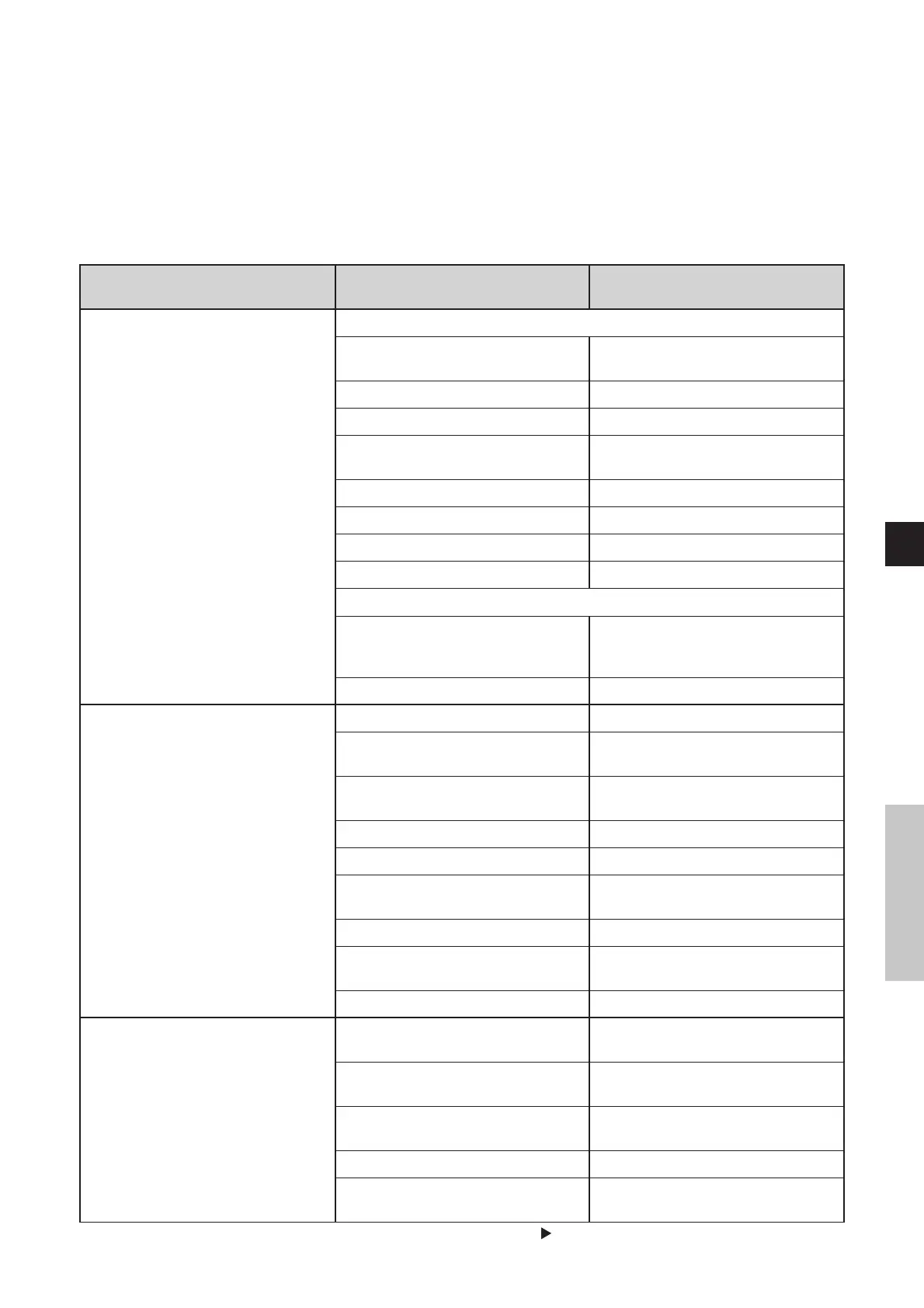

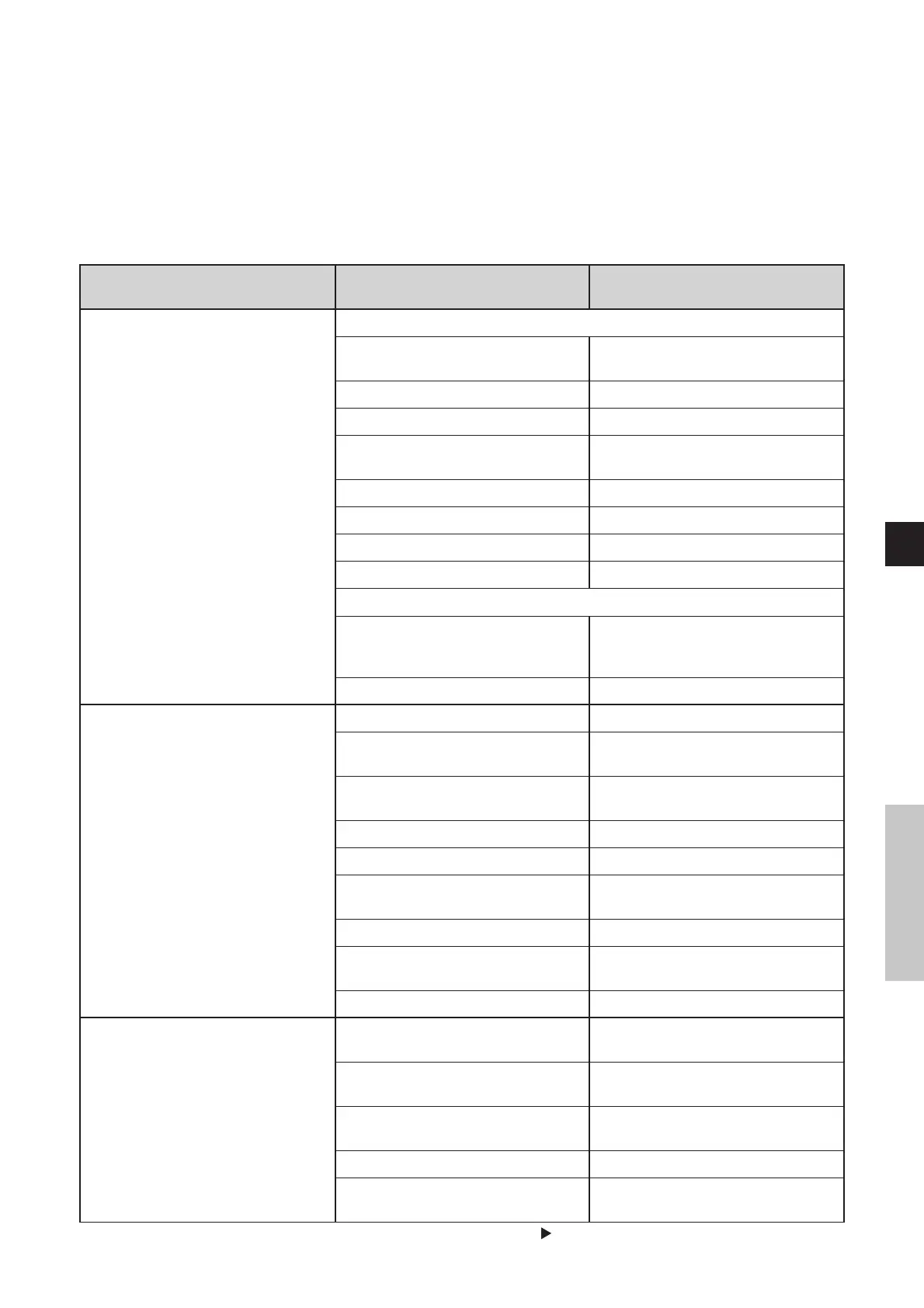

Incidents Causes Corrective actions

The vacuum pump does not produce

a vacuum (continued)

Ultimate pressure obtained: a few 7.5 x10

-3

Torr (10

-2

mbar)

Gas ballast knob open (or supplied

with dry nitrogen C1,C2 Series).

• Close the gas ballast or stop the dry air

supply.

O-ring pinched.• Replace by a new one.

One of the seals is damaged.• Replace by new ones.

One of the HP safety valves is

damaged.

• Replace the HP safety valve.

Lubrication holes blocked.• Disassemble and clean.

Incorrect anti-noise device setting.• Repeat the assembly and setting.

Part forgotten in reassembly.• Repeat the reassembly.

Filter cartridge clogged. Replace by a new cartridge.

Accessories

At the pump exhaust, the installation

produces an exhaust pressure of

1,125 Torr (1.5 bar).

• Check the installation.

Oil mist eliminator cartridge clogged.• Replace.

Noisy pump Oil level too high.• Drain and fill with a new oil.

Oil contaminated (presence of

particles).

• Drain, flush and refill with clean oil.

Pump not prepared for the oil used.• Check the pump configuration or the

type of oil.

Incorrect motor power supply.• Check the power supply.

Motor bearings damaged.• Replace the motor after inspection.

Motor coupling incorrectly set or

damaged.

• Check the setting, replace the motor

coupling.

Incorrect fan assembly.• Check the assembly.

Incorrect anti-suckback device

assembly.

• Repeat the assembly.

Vanes damaged or stuck.• Replace the vanes.

Pump too hot Ambient temperature too high.• Check that the temperature is between

12 and 45 °C.

Pump placed in a poorly ventilated

place or vents blocked.

• Check the installation.

Operation at high pressure

P > 22 Torr (30 mbar).

• Study an outside cooling drvice.

Excess pressure at exhaust.• Check the exhaust line.

Motor in over-voltage or motor in

short-circuit.

• Check the voltage, replace the motor.

All series C1 C2 C1 and C2

Loading...

Loading...