EN – 41

ENMaintenance

Maintenance

Maintenance

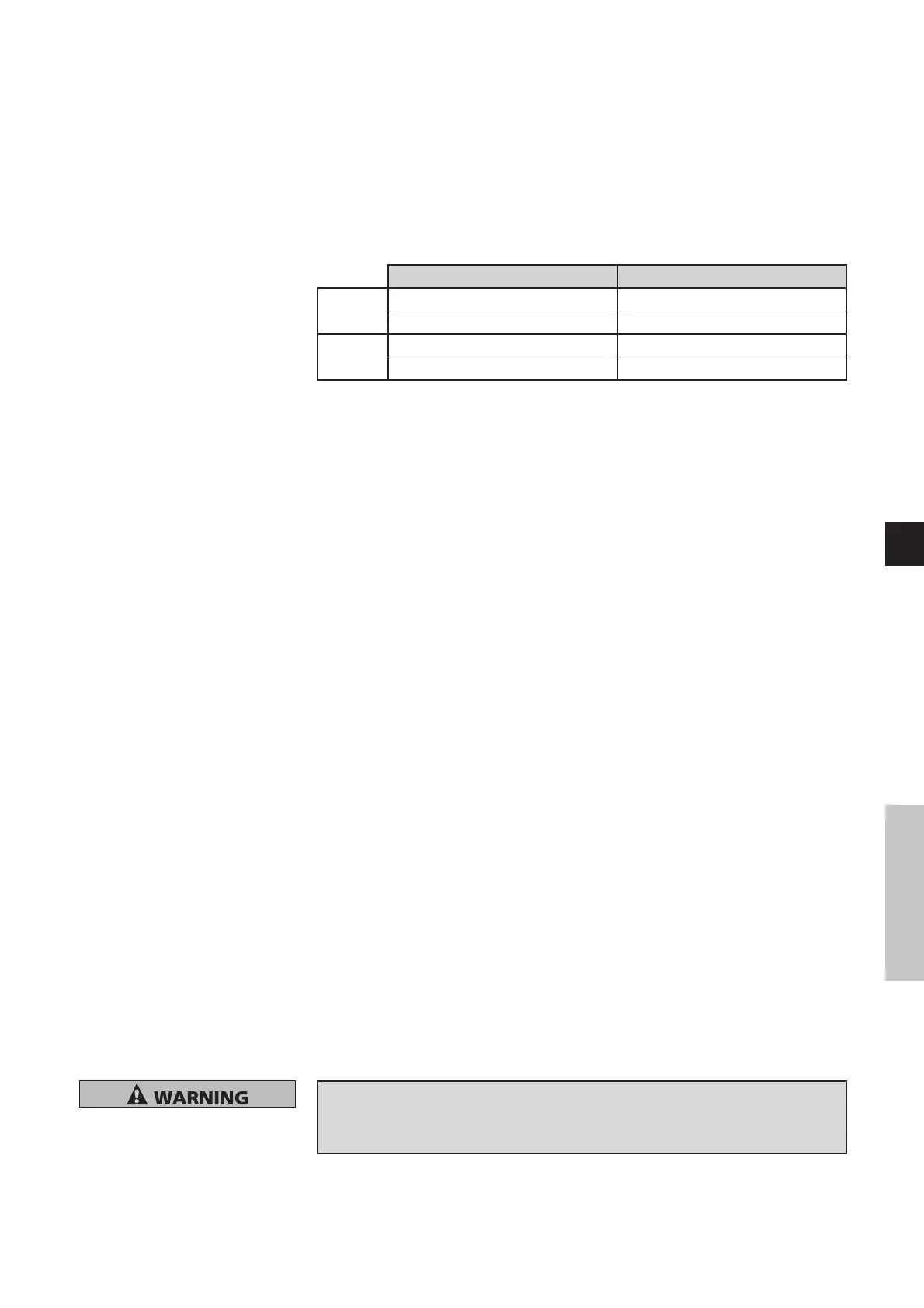

frequency

Frequency Operating conditions

Oil

6 months “normal”, 24h per day

1 year “normal”, < 12h per day

Pump

1 year “normal”, 24h per day

2 years “normal”, < 12h par day

The frequency values are minimum values for «normal» operating conditions: pressure

< 1 mbar (0.75 Torr), clean and non-corrosive gas.

An incorrect ultimate vacuum or a reduction in pumping speed are signs that

the oil has deteriorated.

The periodic inspection of the state of the oil is performed by comparison with a

sample of new oil in order to check the level of contamination or deterioration of the

lubricant.

The frequency at which oil is renewed is adapted to the type of operation:

If the oil is cloudy, this indicates that condensables have been absorbed during

pumping. The oil can be regenerated using the gas ballast (see page 31).

A thickening of the oil, together with a blackish color and a “burnt” smell indicate

that the oil has deteriorated. Drain the pump and flush it.

When the lubricating oil is expensive (fluorocarbon synthetic oils), the use of an oil mist

eliminator allows oil recovery after deposition.

The oil should be changed every 6 months. This value is given as a guide only.

It may be extended to 1 year if the ultimate vacuum required is sufficient (for roughing

pumps).

Similarly, if the pump is stopped frequently for long periods, the oil should

be changed at intervals of 6 months to a maximum of 1 year (oil may become

sticky).

Note: Every pumping operation is different. This oil must therefore be changed at

intervals adapted to each specific application.

The use of accessories (see page 14) can reduce the frequency of these maintenance

operations.

Roughing

Maintenance of the

accessoiries

When an adixen accessory is connected to the pump, periodically it is necessary to

make accessory overhaul.

Study the accessory user’s manual and make sure you follow the safety instructions

it gives regarding protection of personnel: operator could be in contact with process

residues on the exhaust which could cause severe injury or death. Ask your safety

department for instructions according to the local regulations.

When an oil mist eliminator is installed, check periodically at the exhaust

orifice that:

- the exhaust valve can move, so the exhaust is not blocked,

- the exhaust valve can move, no overpressure in the oil casing.

Loading...

Loading...