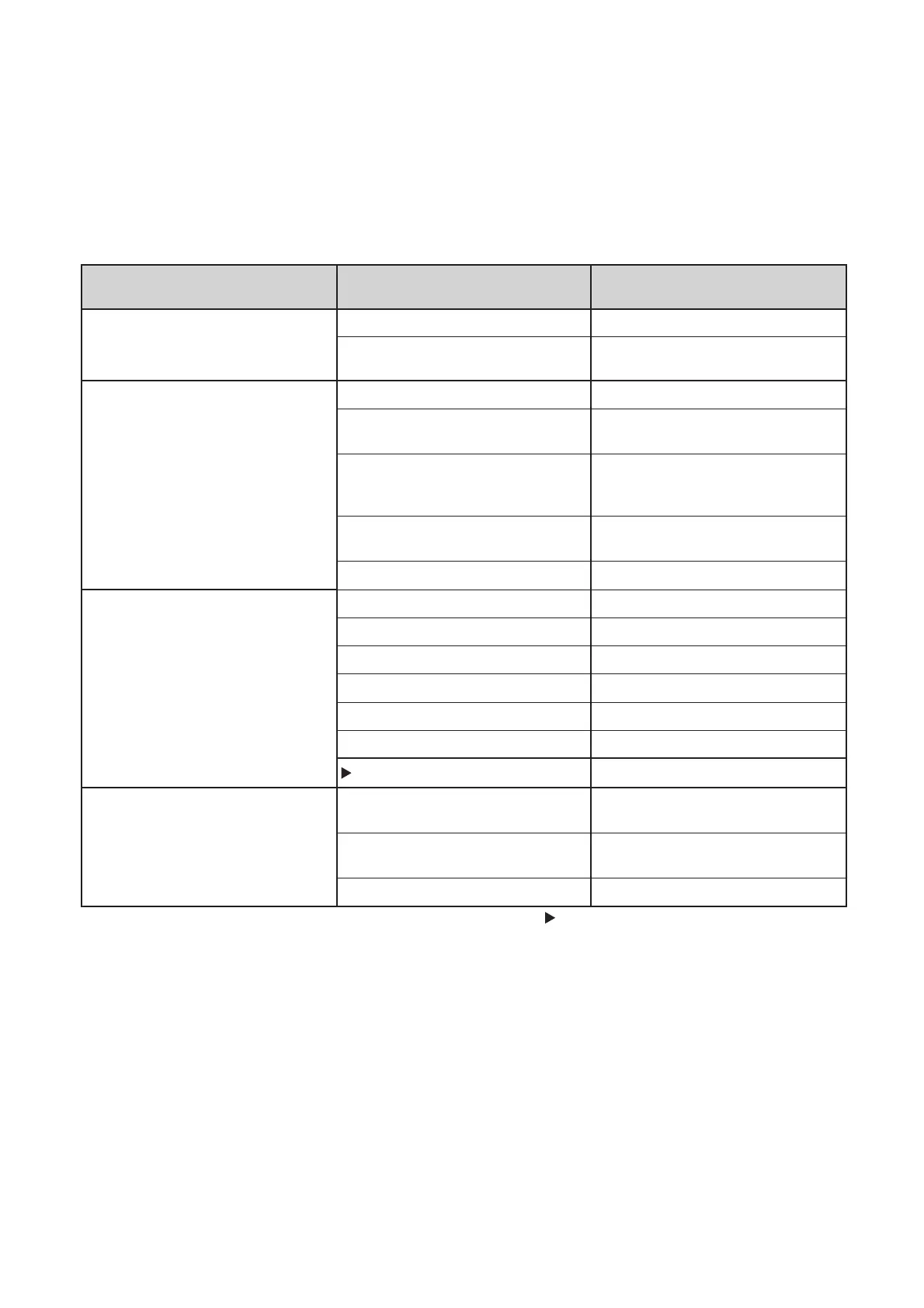

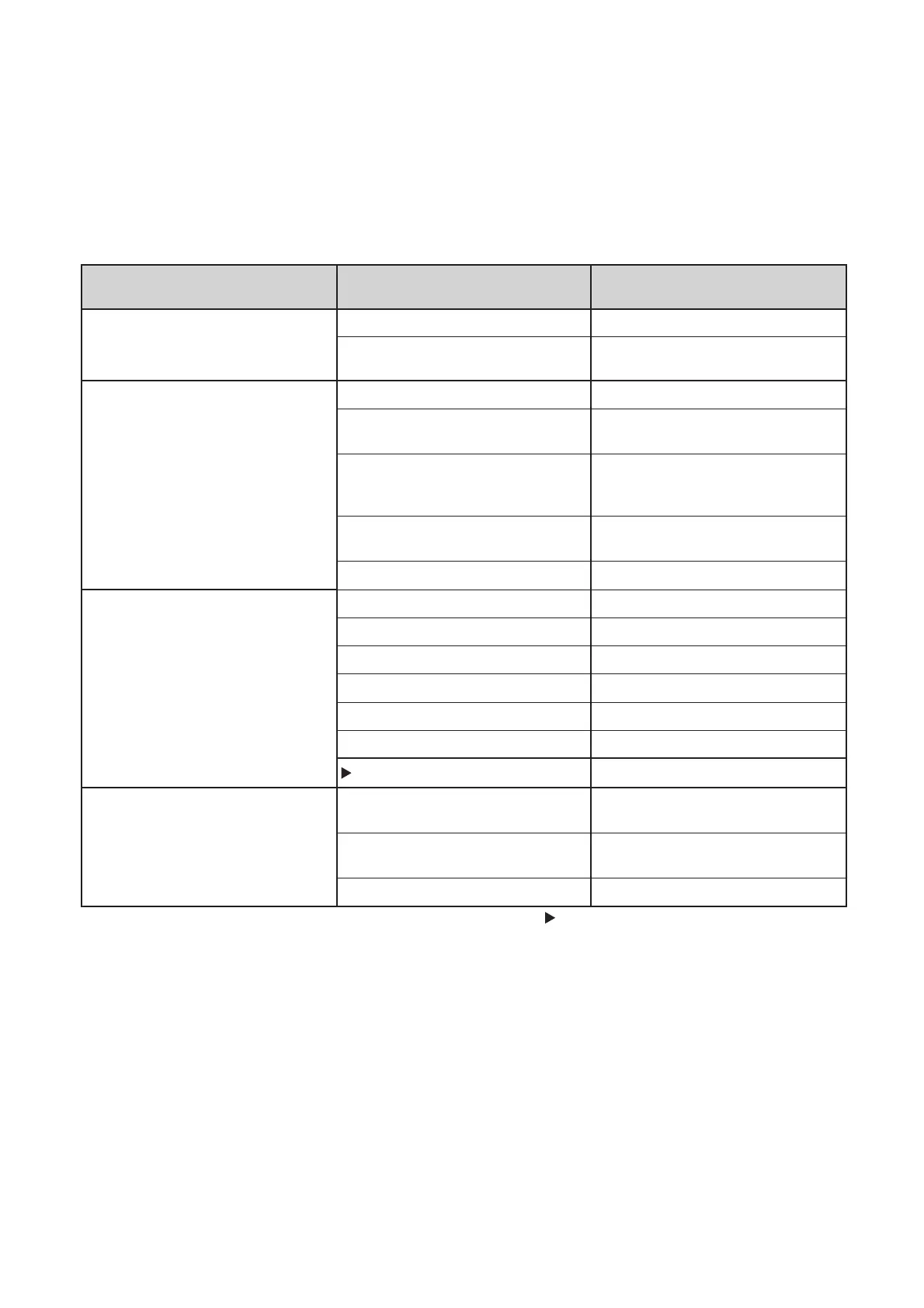

EN – 40

Incidents Causes Corrective actions

Pump too hot (cont’ed) Oil contaminated.• Drain, flush and refill with clean oil.

Pump not prepared for the oil used

or oil unsuitable.

• Check pump configuration or type of oil.

Considerable oil losses Oil level too high.• Drain and fill with a new oil.

Operation at high pressure.• Use an HP type oil mist eliminator with

oil recovery.

Gas ballast open:

1 - accidentally

2 - pumping of condensable vapors.

•

1 - Close.

2 - Use a condensate collector.

Leak at oil case seal or at front seal.• Check the assembly and replace the

seals if necessary.

Purges gas flow too important.

Readjust.

Poor pump tightness when

switched off

Gas ballast open.• Close the gas ballast.

Safety valve damaged.• Replace by a new one.

Incorrect anti-suckback assembly.• Repeat the assembly.

O-ring pinched.• Replace by a new one.

Seals damaged.• Replace by a new one.

Oil contaminated.•

Drain, flush and refill with clean oil.

Using a plastic HP valve (not tight)

Check the installation. Contact us.

Oil in plate Oil case and frame cleaned poorly

during reassembly.

• Remove the base and clean.

Oil case seal pinched.• Disassemble the oil case, clean the faces

and refit a new seal.

Front seal damaged or felt saturated.• Replace by new ones.

All series C1 C2 C1 and C2

Troubleshooting and corrective actions

(cont’d)

Loading...

Loading...