Revision 3 | Operating instructions sample cleaner MLN

Clean the deawner with a damp cloth and/or compressed air.

After cleaning, re-mount the filling container at the specified place.

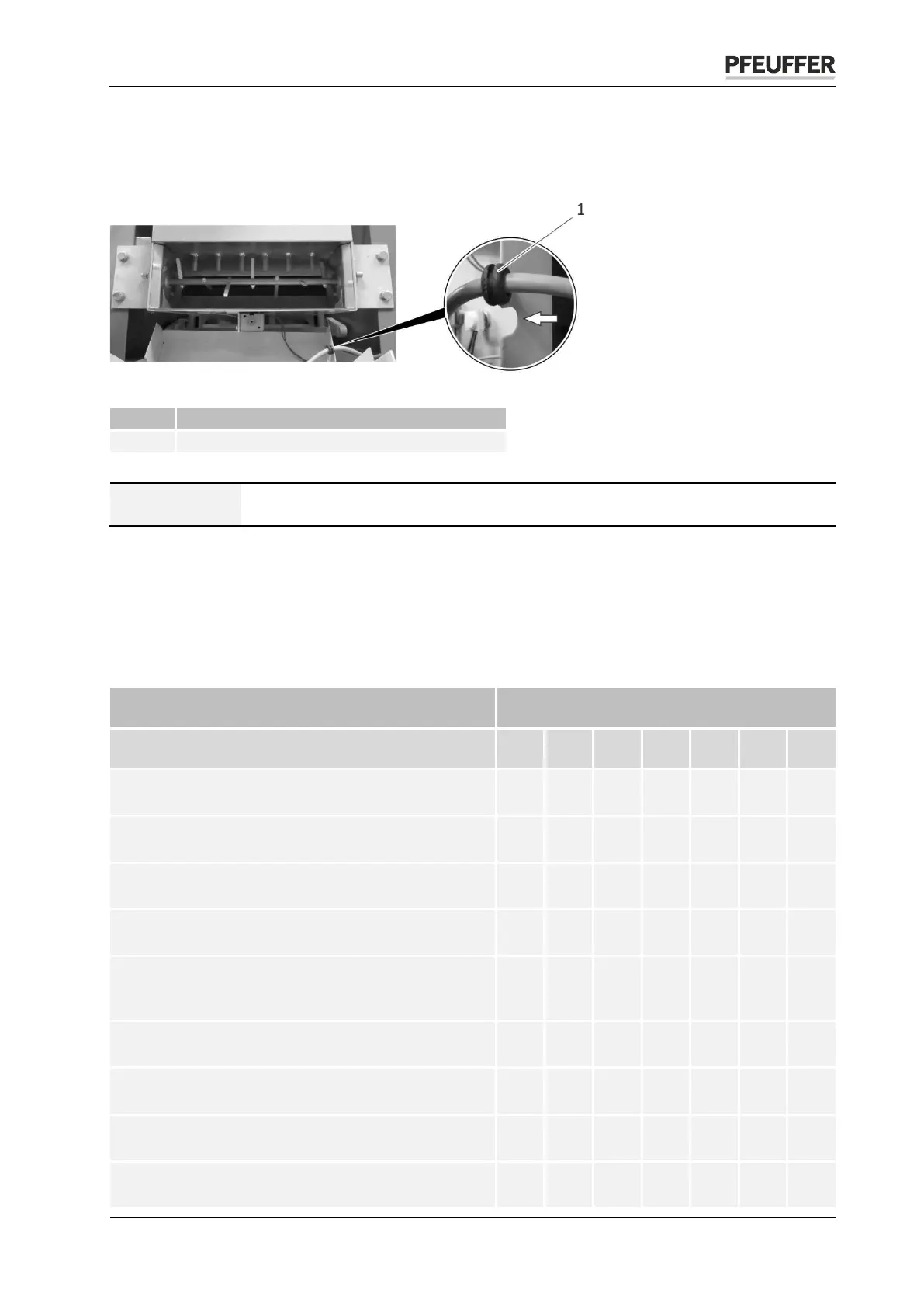

Insert the rubber bush on the casing through the recess; refer to figure 19.

Figure 19: Rubber bush at the filling container

NOTICE

Make sure that you do not damage, cut or pull out any cables.

Secure the side screws at the filling container.

8.2 Lubrication

Maintenance-free bearings are used in sample cleaner MLN. Lubrication is not necessary.

8.3 Inspection interval and functional test

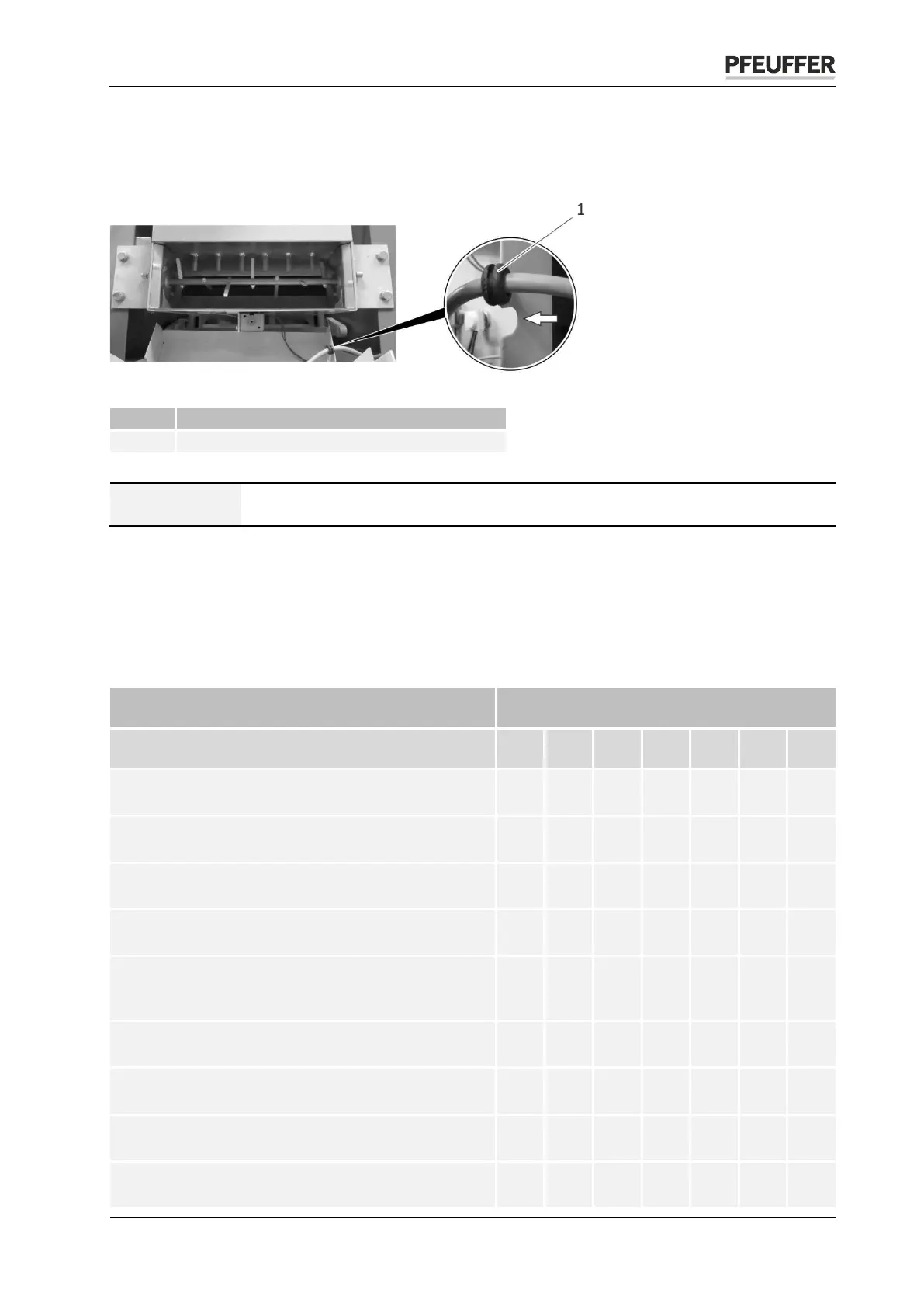

Assembly Interval during single-shift operation

Normal functional tests: w m ¼ j ½ j 1 j 2 j LD

Buttons and switches X

Mains isolator (plug/socket combination) X

Markings and warnings present and legible (via visual

inspection)

X

Check if wires are tight X

Check whether all the plug, screw and clamped

connections are tight and if necessary, re-tighten

X

Rubber bearings (sieve mode) X

Check the belt tension and inspect for damages X

Functional test of the drive motors X

Electrical test as per VDE X

Loading...

Loading...