Mixing pump RITMO L / RITMO M Overview - Operation

Work on troubleshooting

50

2016-02-17

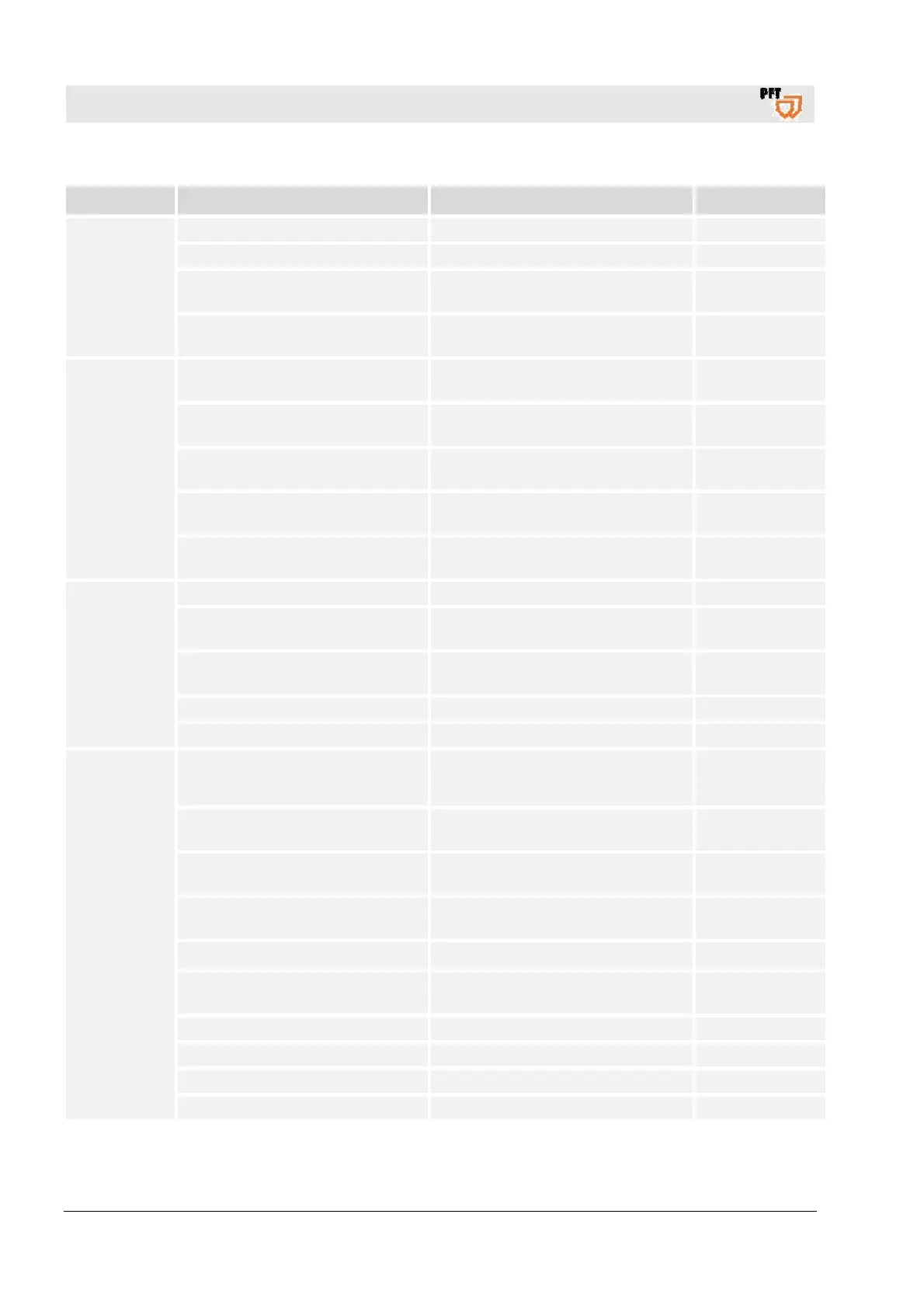

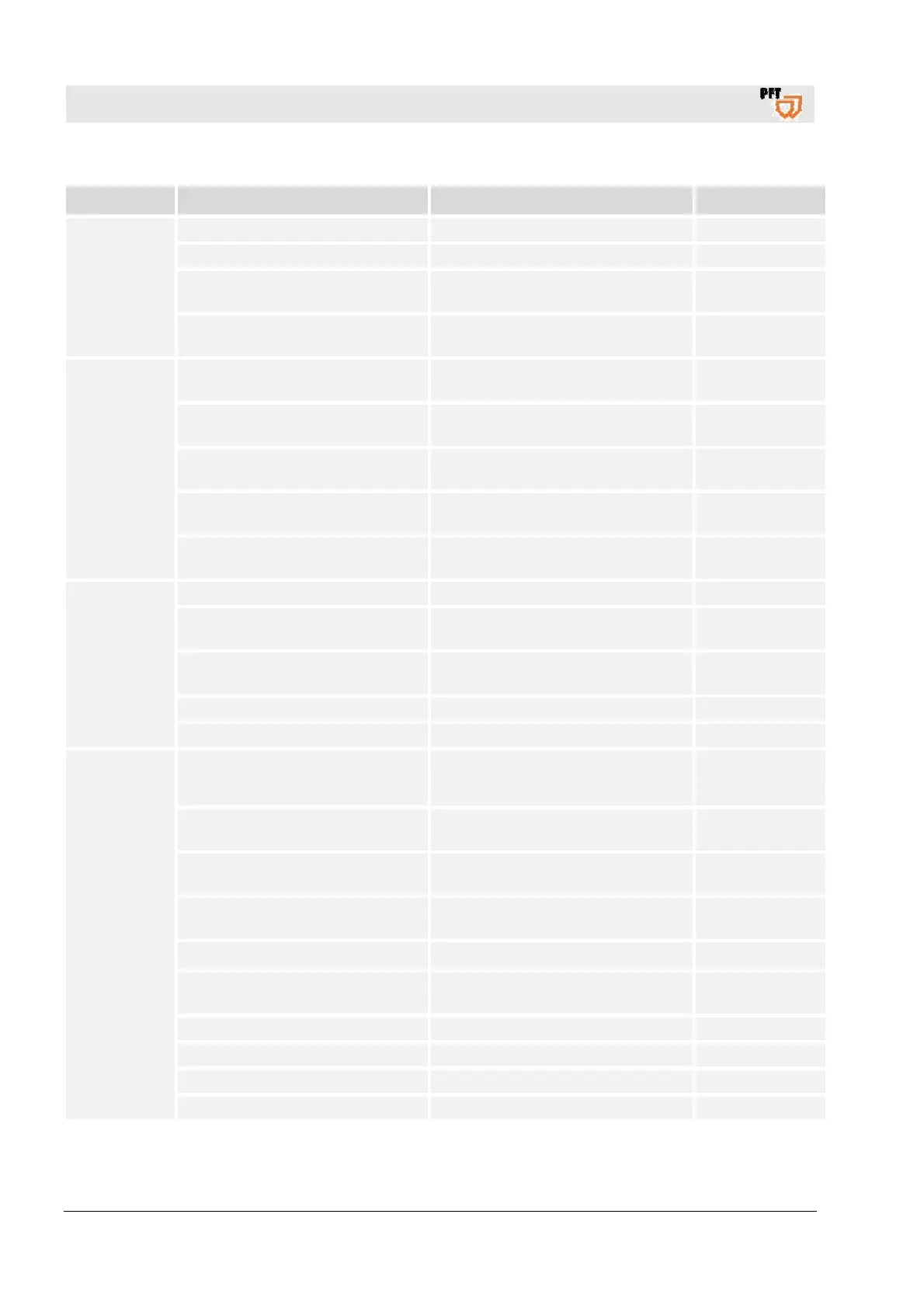

Fault Possible cause Solution Rectification by

Machine

stops after a

short while

Strainer screen contaminated Clean or replace strainer Operator

Strainer sieve of pressure relieve

Clean or replace strainer Operator

Hose connection or water pipe too

small

Increase dimensions of hose

connection or water pipe

Operator

Water suction tube too long or

suction pressure too low

if required, connect additional

pressure booster pump upstream

Service engineer

Machine does

not switch off

Air pressure safety switch set

incorrectly or defective

Adjust or replace air pressure safety

switch

Service engineer

Air pressure hose defective or

seals defective

Replace air pressure hose, replace

seals or check compressor

Service engineer

Air tap at the spraying gun

defective

Replace air tap Service engineer

Power provided by compressor is

too low.

Check compressor Service engineer

Air duct is not connected to the

compressor

Connect air duct to the compressor Operator

Mortar flow

ceases (air

bubbles)

Bad mixture in mixing tube Add more water Operator

Material is clumped and narrows

the mixing tube inlet

Add more water or clean agitator or

replace

Operator

Material in mixing tube has

become wet

Empty mixing tube, dry it and start

again

Operator

Agitator defective Replace agitator Operator

Driving dog defective Replace driving dog Service engineer

Mortar flow

"thick-thin"

Too little water

Increase the water quantity by 10%

for approx. ½ minute and then turn

down slowly

Operator

Water safety switch set incorrectly

or defective

Adjust or replace water safety switch

Service engineer

Agitator defective; no original PFT

agitator

Replace agitator with original PFT

agitator

Operator

Pressure reducer set incorrectly or

defective

Adjust or replace pressure reducer Service engineer

Rotor worn or defective Replace rotor Service engineer

Stator worn or clamping bracket

tightened too little

Replace stator or re-tighten

clamping bracket

Service engineer

Clamping bracket defective (oval) Replace clamping bracket Service engineer

Inner wall of mortar hose defective

Replace mortar hose Operator

Rotor too deep in pressure flange Replace pressure flange Service engineer

No original PFT spare parts Use original PFT spare parts Service engineer

Loading...

Loading...