Service Modes, Error Codes, and Fault Finding

EN 16 A02U AA5.

5.6.2 How to Enter

Use one of the following methods:

• Enter the SDM (only via soldering pads marked "FOR

SERVICE" on the SSB). The blinking front LED will show

the entire contents of the error buffer (this works in "normal

operation" mode and in "protection" mode). In order to

avoid confusion with RC5 signal reception blinking, this

LED blinking procedure is terminated when an RC5

command is received.

• Transmit the commands "MUTE", "06250x", and "OK" with

a normal RC (where "x" is the position in the error buffer

that has to be displayed). With x= 1, the last detected error

is shown, x= 2 the second last error, etc.... When x= 0, all

errors are shown.

• "DIAGNOSE X" with the DST (where "x" is the position in

the error buffer that has to be displayed). With x= 1, the last

detected error is shown, x= 2 the second last error, etc....

When x= 0, all errors are shown.

Note: It can take some seconds before the blinking LED starts.

5.7 Protections

5.7.1 Introduction

Fault protections are introduced to avoid unacceptable

temperature rising and burning hazards. If a fault situation is

detected, an error code will be generated and if necessary, the

set is put in protection mode.

The protection mode is indicated by the blinking of the front

LED at a frequency of 3 Hz (or by a coded blinking in special

cases). For the customer, it is made impossible to switch "on"

the set during a protection.

It is possible to determine the type of fault by interpreting the

blinking pattern of the LED indicator. It is also possible to read

out the error codes from the NVM via ComPair. It is possible to

de-activate the protection states in Service Default Mode.

The following protections are implemented:

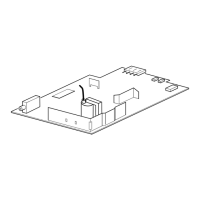

Table 5-2 Protections overview

The protections are split up in the following order:

• I2C related protections.

• ADOC related protections (via polling on I/O pins or via

algorithms).

• DOP related protections (mainly for deflection items).

• Hardware errors that are not sensed by the OTC (e.g.

vertical flyback protection, bridge coil protection, E/W

protection, arcing protection).

All faults detected are re-checked five times before the

protection mode is triggered. It should be noted that supply

fault detection/protection must be enabled only after the

chassis power supply has been established. Likewise, after the

line drive starts, the deflection detection/protection must be

enabled. To prevent false activation of protection mode during

power mode transitions, interrupts related to supply fault and

deflection fault are disabled.

5.7.2 I2C Related Protections

In normal operation, some registers of the I2C controlled ICs

are refreshed every 200 ms. During this sequence, the I2C

busses and the I2C ICs are checked.

An I2C protection will take place if the SDA and SCL lines are

short-circuited to ground, or to each other. An I2C error will also

occur, if the power supply of the IC is missing.

5.7.3 ADOC Related Protections

If a protection is detected at an ADOC input, the uP will start to

scan all protection inputs every 200 ms for five times. If the

protection on one of the inputs is still active after 1 s, the

microprocessor will put the set in the protection mode. Before

the scanning is started, a so-called "ESD refresh" is carried out.

This is done, because the interrupt on one of the inputs is

possibly caused either by a flash or by ESD. As a flash or ESD

can influence IC settings, the key ICs are initialized again, to

ensure the normal picture and sound conditions of the set.

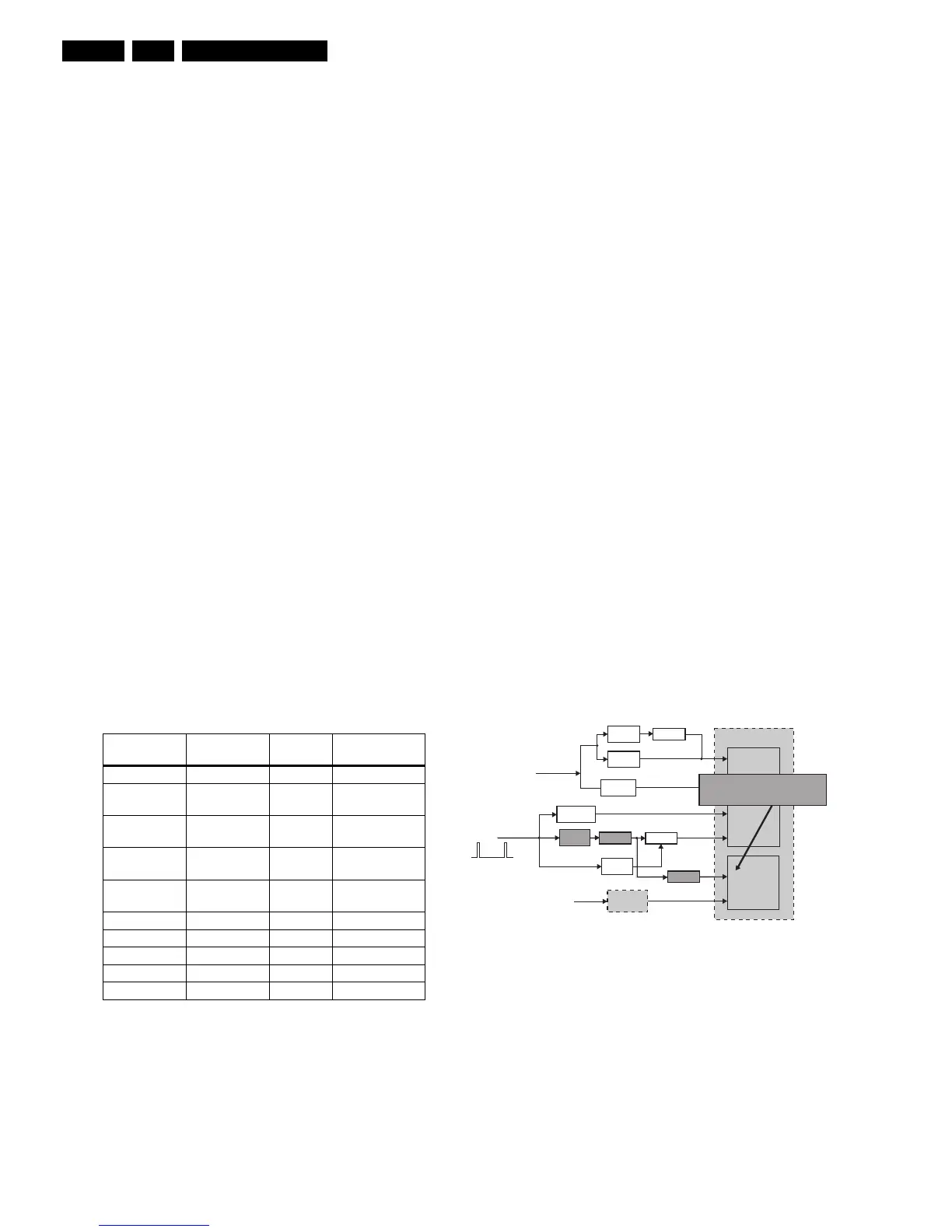

Under Voltage Protection

The under voltage protection is needed due to the non-isolated

chassis architecture used in A02. Whenever there is a short

circuit in the Deflection yoke coil or in the Audio power supply,

the averaged Horizontal Flyback Voltage (HFB_XRAY_PROT)

will fall. After signal conditioning, this voltage is fed to the

"KEYBOARD_ADC" input. When this input of the MIPS

controller is less than a certain level, the under voltage

protection is activated. This is done by the normal keyboard

polling mechanism.

The protection mode is activated after five consecutive

occurrences. Response time required is 2 s. This is to avoid set

going to under voltage protection mode during start up, since

the HFB will only be stable w.r.t. mains on for about 1.6 s.

Figure 5-2 Under Voltage Protection

+8V Protection

Hardware is employed for the detection of +8V supply fault. A

hardware interrupt (MPIF-IRQ) is generated by the MPIF when

the +8V supply falls below the IC specification.

To avoid false detection, the corresponding interrupt sub

routine checks the status of "ASUP" bit in the MPIF status

register for five times consecutively with an interval of 200 ms

before triggering the protection mode. Response time required

is 1.2 s.

Protection Detection

method

Bit name Detection

Under Voltage Via ADC (KB) ADC (KB) ADC input

+8V Supply Via MPIF_IRQ ASUP MPIF internal

register

Horizontal

fly-back

Via interrupts NOHFB ADOC internal

register (DOP)

X-ray Via interrupts XPROT ADOC internal

register (DOP)

Beam Current Via interrupts BCF ADOC internal

register (DOP)

Flash Hardware ctrl - Hardware

Arc Hardware ctrl - Hardware

Vertical Hardware ctrl - Hardware

East/West Hardware ctrl - Hardware

Bridge coil Hardware ctrl - Hardware

-Ve

Threshold

+Ve

Threshold

Signal

conditioning

Switch

MPIF

+8V

Voltage

divider

Signal

conditioning

FLASH

DOP

ADOC

BCL

NOHFB

XPROT

ADC

KEYBOARD

MPIF IRQ

MIPS CORE

EHT-INFO

HFB_X-RAY-

Switch

Inverter

-Ve

Threshold

<16Vp-p

When hor. Defl. coil or sound amp

s/c, HFB will drop at <16Vpp level.

The switch will put ADC keybd to low.

Switch

E_13950_016.eps

040304

Loading...

Loading...