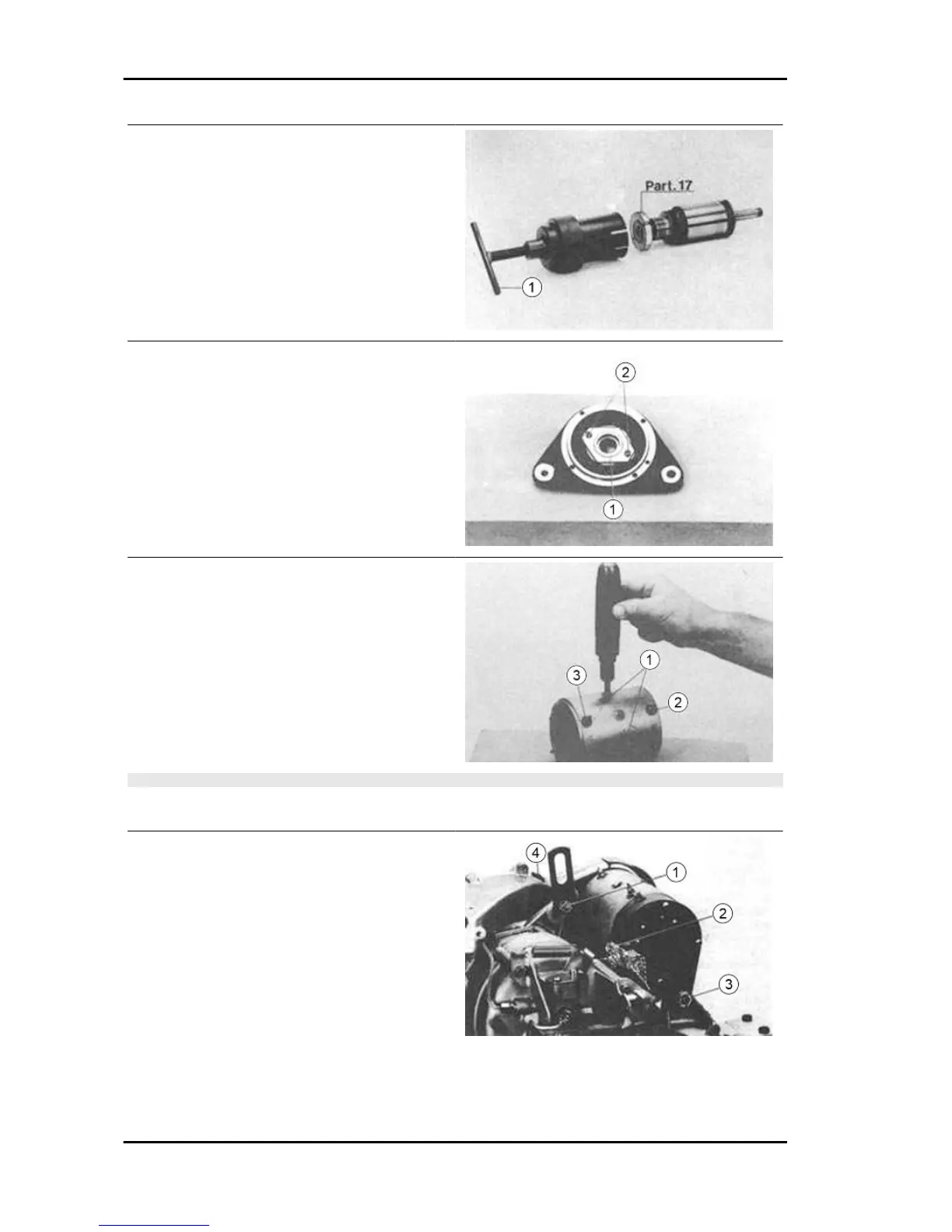

BALL BEARING

Fit the specific tool fitted with comp. 17, act on the

central screw (1) and remove the bearing and the

washer.

Specific tooling

T.0014499 Bearing extractor

PULLEY SIDE BALL BEARINGS

Remove the flange using the four screws, unscrew

the two screws (2), remove the plate (1) and from

the part opposite to that shown in the figure, with

a punch of external Ø 22 mm eject the bearing.

FIELD WINDINGS

With the help of a strike screwdriver, as shown in

the figure, remove the four anchor screws (1) of

the windings, unscrew the two nuts (3) and (2) and

remove the windings themselves.

N.B.

THE UNIT IS ASSEMBLED PROCEEDING IN THE OPPOSITE ORDER AS FOR REMOVAL AS DE-

SCRIBED ABOVE.

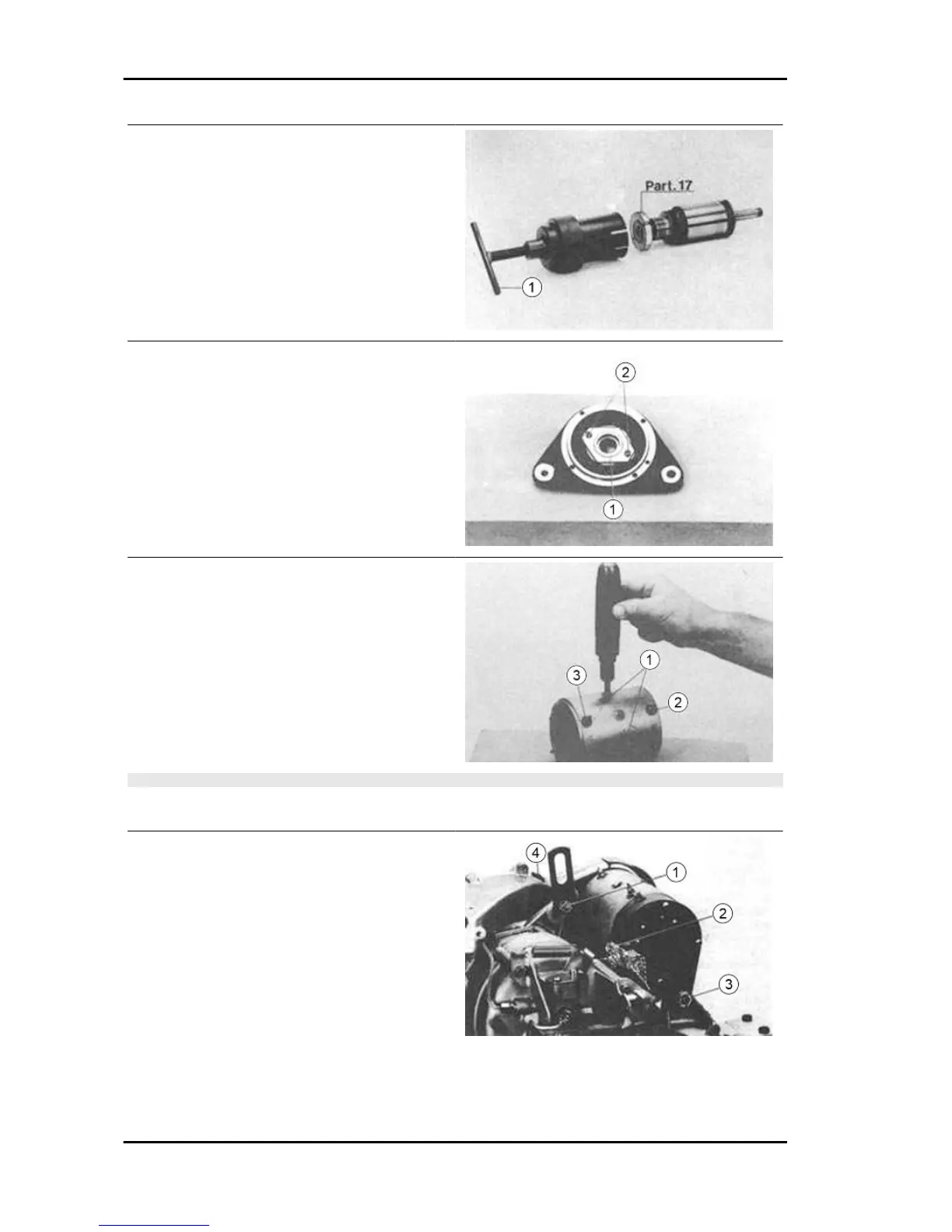

DYNAMOTOR - FITTING

The Dynamotor is assembled on the engine unit

as described above: position the dynamotor, an-

choring it to the crankcase with the relative bolts

without locking them, adjust the belt by moving the

dynamotor toward the rear of the engine and lock

the bolt (1), then the other two in the order shown

in the figure.

Remove the cap from the track (4) on the scroll

putting a pencil in contact with the belt, push the

pencil to the bottom and check its course; the belt

Electrical system APE TM Benzina

ES - 64

Loading...

Loading...