User manual - ATR224 - DRR224 - 15

7.6 Automatic / Manual regulation for % output control

This function allows to switch from automatic functioning to manual command of the output

percentage.

With par. 48

A . m a .1 . (for regulation loop 1) it is possible to select two modes.

1 First selection (

enab.) allows to enable with FNC the writing p.--- on display 1, while on display 2 is

showed

autom.

Press SET to visualize manu.; it’s now possible, during the process visualization, modify through the

keys

c

and

d

the output percentage. To back to automatic, with the same procedure, select autom.

on display 2: immediately led MAN switches off and functioning backs to automatic.

2 Second selection (

en.sto.) enables the same functioning but with two important variants:

• If there is a temporary power failure or after switch-off, the manual functioning as well as the

previous output percentage value will be maintained at restarting.

• If the sensor breaks during automatic functioning, the controller switches to manual mode while

maintaining the output percentage command unchanged as generated by the PID immediately

before breakage.

Ex: on an extruder the command in percentage of the resistance (load) is maintained also in case of

input sensor failure.

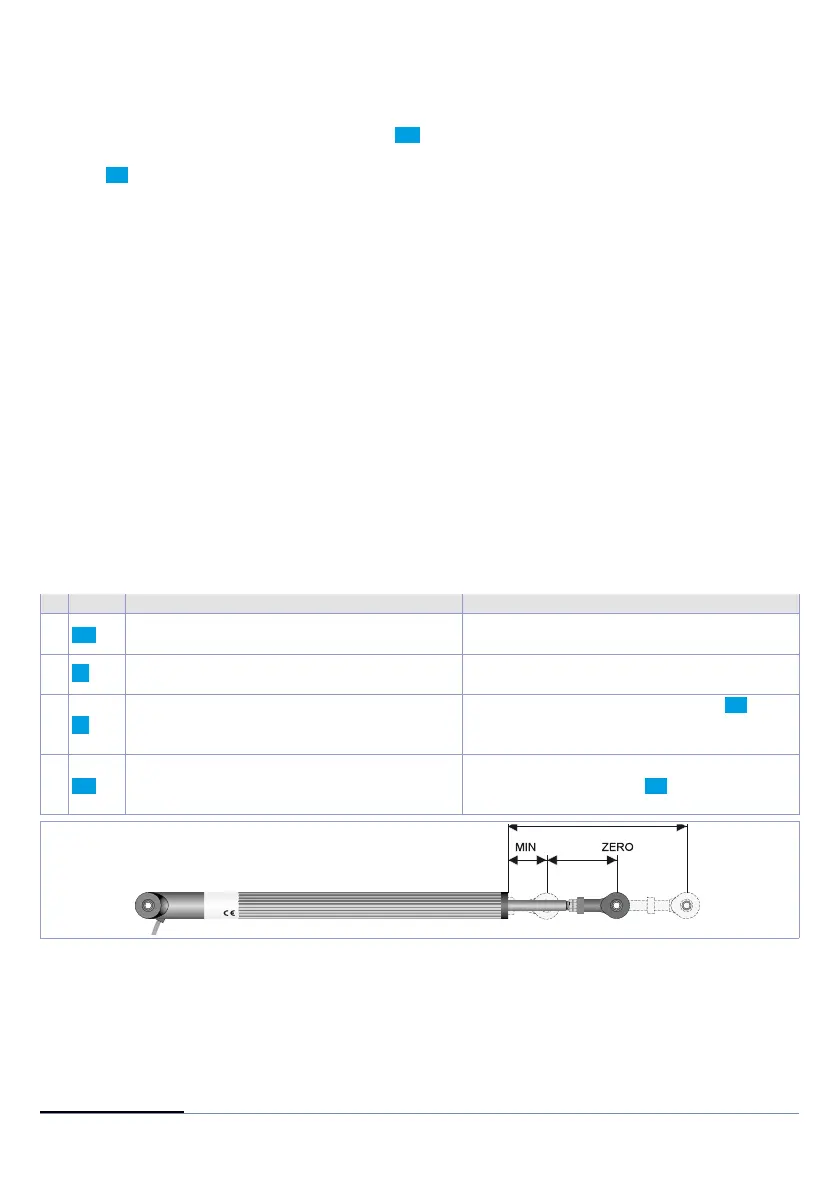

7.7 LATCH ON Function

For use with input po t. and with linear input (0..10 V, 0..40 mV, 0/4..20 mA) it is possible to associate start

value of the scale (par. 4

L.L.i .1) to the minimum position of the sensor and value of the scale end (par. 5

u.L.i.1) to the maximum position of the sensor (par. 10 L t c .1 configured as stndr).

It is also possible to fix the point in which the controller will display 0 (however keeping the scale range

between

L.L.i .1 and u.L.i. 1) using the

“virtual zero”

option by selectin u.0.sto. on par. 10 L t c .1 . Selecting

u.0.t.on. the virtual zero must be reset at each switching on; selecting u.0.sto. the virtual zero will remain

fixed once calibrated. To use the LATCH ON function, configure the par.

L t c .1

1

Then refer to the following table for the calibration procedure:

Press Display Do

1

FNC

Exit parameters configuration. Display 2

visualizes writing

La tc.

Place the sensor on minimum operating

value (corresponding to

L.L.i .1)

2

Store value on minimum.

Display shows

Lo w .

Place sensor on maximum operating value

(corresponding to

u.L.i.1).

3

Store value on max.

Display shows

Hi G .

To exit standard proceeding press SET.

For

“virtual zero”

setting, place the sensor to

zero point.

4

FNC

Set virtual zero. Display shows

ero .

If

“Virtual zero at start”

is selected, point 4

must be repeated at each starting.

To exit procedure press SET.

1 The tuning procedure starts by exiting the confi guration after changing the parameter.

Loading...

Loading...