6.0/8.1L Electronic Ignition 4B - 11

MEFI 4 - PCM

622527

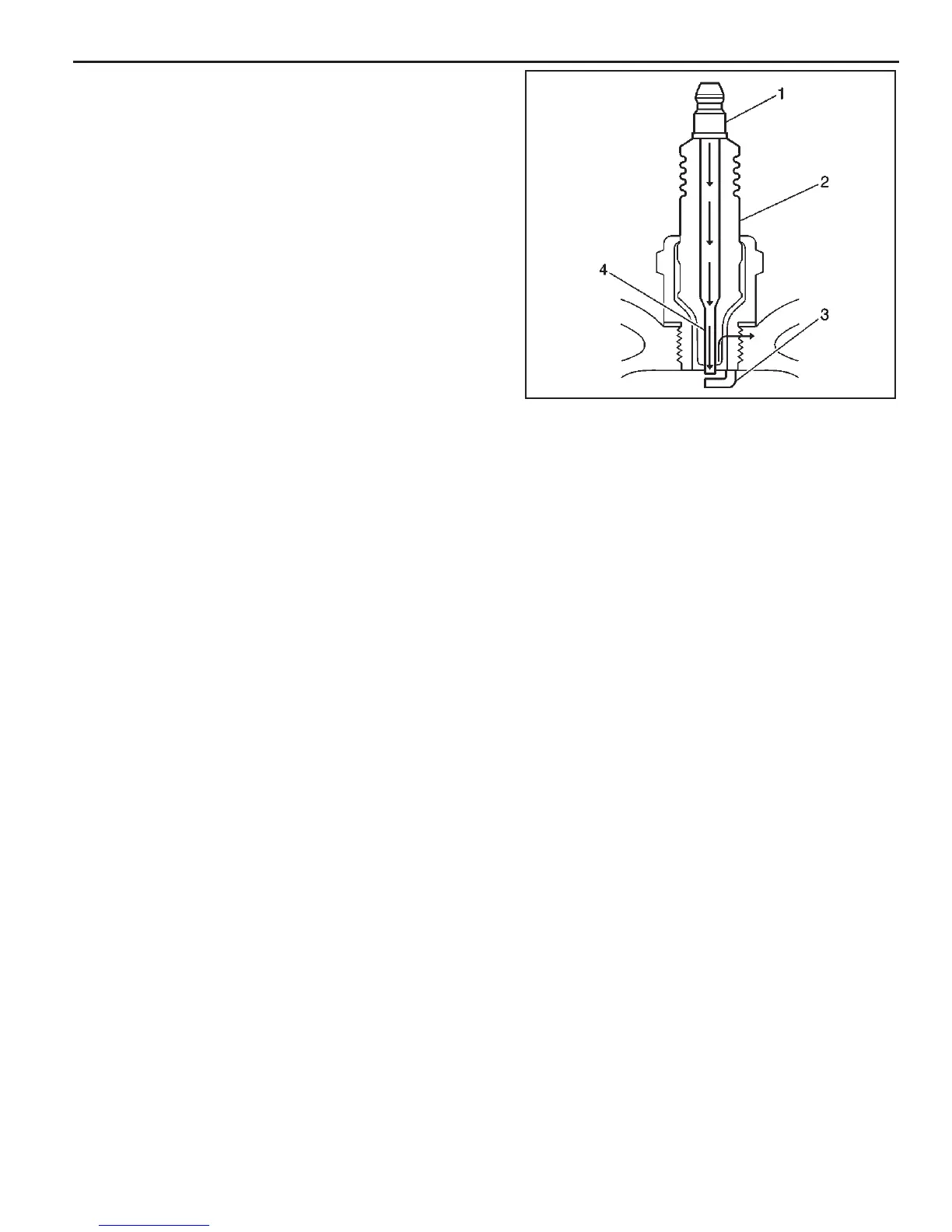

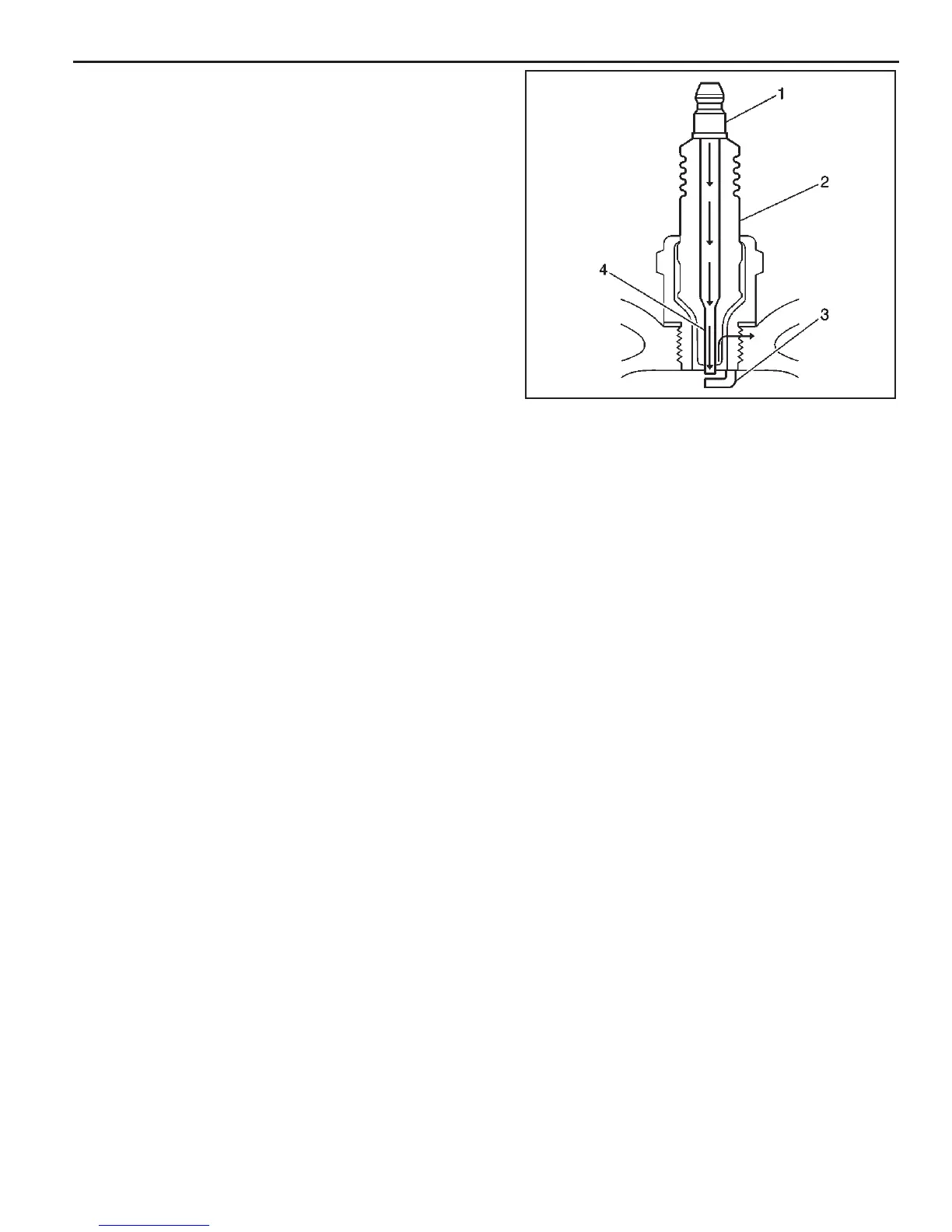

• Inspect for evidence of improper arcing.

– Measure the gap between the center electrode

(4) and the side electrode (3) terminals. An

excessively wide electrode gap can prevent

correct spark plug operation.

– Inspect for the correct spark plug torque.

Insuffi cient torque can prevent correct spark plug

operation. An over torqued spark plug may cause

the insulator (2) to crack.

– Inspect for signs of tracking that occurred near

the insulator tip instead of the center electrode

(4).

– Inspect for a broken or worn side electrode (3).

– Inspect for a broken, worn or loose center

electrode (4) by shaking the spark plug.

• A rattling sound indicates internal damage.

• A loose center electrode (4) reduces the spark

intensity.

– Inspect for bridged electrodes (3, 4). Deposits on

the electrodes (3, 4) reduce or eliminates the gap.

– Inspect for worn or missing platinum pads on the

electrodes (3, 4), if equipped.

– Inspect for excessive fouling.

• Inspect the spark plug recess area of the cylinder

head for debris. Dirty or damaged threads can

cause the spark plug not to seat correctly during

installation.

Spark Plug Visual Inspection

• Normal Operation - Brown to grayish-tan with small

amounts of white powdery deposits are normal

combustion by-products from fuels with additives.

• Carbon Fouled - Dry, fl uffy black carbon, or soot

caused by the following condition:

– Rich fuel mixtures

• Leaking fuel injectors

• Excessive fuel pressure

• Restricted fl ame arrestor/air fi lter element

• Incorrect combustion

– Reduced ignition system voltage output

• Weak coil(s)

• Worn ignition wires

• Incorrect spark plug gap

– Excessive idling or slow speeds under light

loads can keep spark plug temperatures so low

that normal combustion deposits may not burn

off.

Loading...

Loading...