5.0/5.7L Fuel Metering System 3A - 5

MEFI 4 - PCM

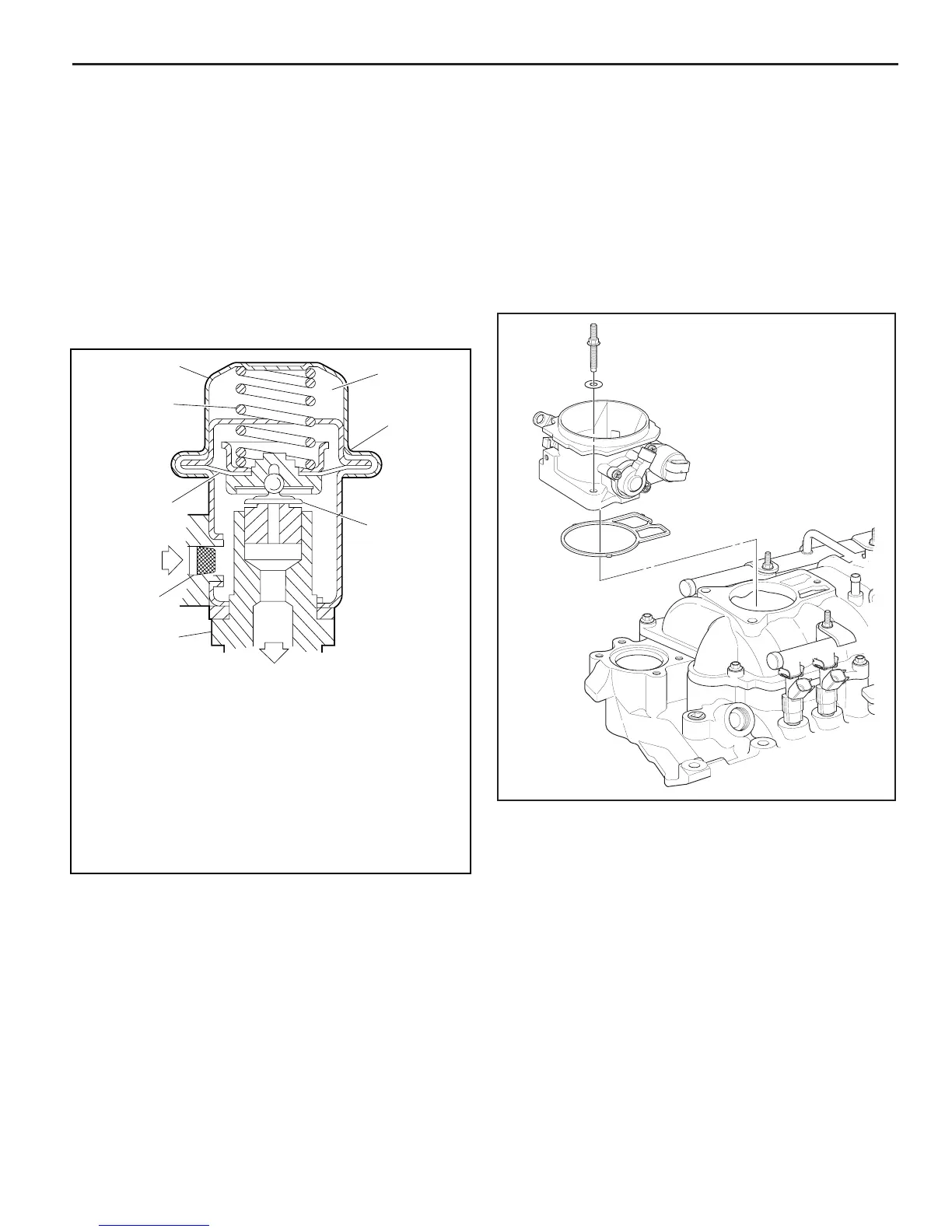

Figure 3-5 - Pressure Regulator Assembly (Typical)

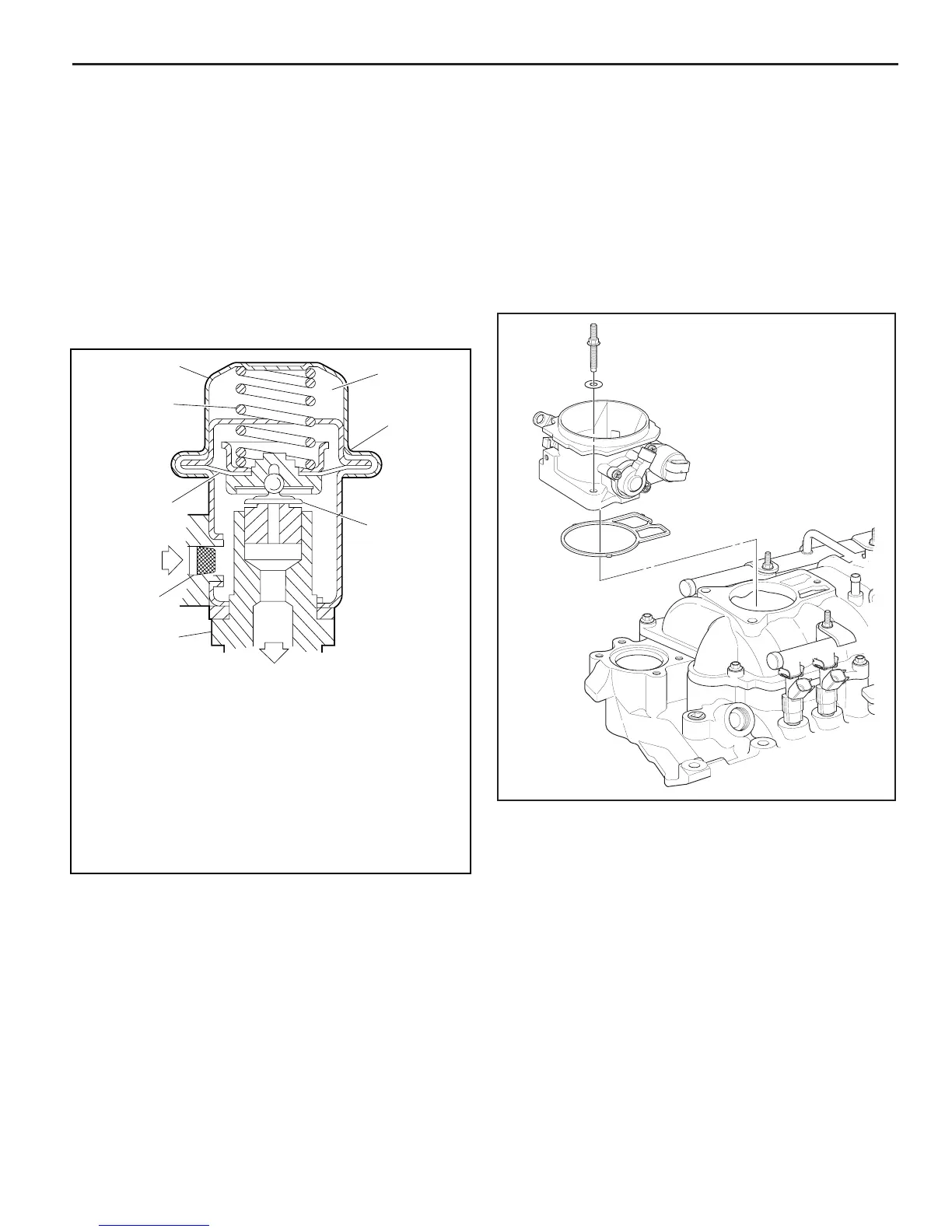

Figure 3-6 - Throttle Body Assembly

1 COVER

2 VACUUM CHAMBER

(VACUUM SOURCE TUBE NOT SHOWN)

3 O - RING SEAL

4 FUEL PRESSURE REGULATOR VALVE

5 BASE ASSEMBLY

6 FILTER SCREEN (IF EQUIPPED)

7 DIAPHRAGM

8 SPRING

NA 0493-SY

1

8

7

6

5

2

3

4

4-11-96

Throttle Body Assembly

The throttle body assembly is attached to the intake

manifold air plenum, and is used to control air fl ow into the

engine, thereby controlling engine output (Figure 3-6). The

throttle plates within the throttle body are opened by the

driver through the throttle controls. During engine idle, the

throttle plates are closed, and air fl ow control is handled by

the Idle Air Control (IAC) valve, described below.

The throttle body also provides the location for mounting

the TP sensor and for sensing changes in engine vacuum

due to throttle plates position.

Pressure Regulator Assembly

The pressure regulator is a diaphragm-operated relief

valve with fuel pump pressure on one side, and regulator

spring pressure and intake manifold vacuum on the other

side (Figure 3-5). The regulator’s function is to maintain

a constant pressure differential across the injectors at all

times. The pressure regulator compensates for engine load

by increasing fuel pressure as engine vacuum drops.

With the ignition “ON,” engine “OFF” (zero vacuum),

fuel pressure at the pressure test connection should be

284-325 kPa (41-47 psi). If the pressure is too low, poor

performance or a “no-start” may result. If pressure is too

high, excessive odor may result.

Loading...

Loading...