5.0/5.7/6.0L/8.1L General Information 1 - 11

MEFI 4 - PCM

OUTER JACKET

MYLAR

DRAIN WIRE

DRAIN WIRE

1REMOVE OUTER JACKET.

2UNWRAP ALUMINUM/MYLAR TAPE. DO NOT

REMOVE MYLAR.

1LOCATE DAMAGED WIRE.

2REMOVE INSULATION AS REQUIRED.

3SPLICE TWO WIRES TOGETHER USING SPLICE

CLIPS AND ROSIN CORE SOLDER.

3UNTWIST CONDUCTORS. STRIP INSULATION AS

NECESSARY.

6TAPE OVER WHOLE BUNDLE TO SECURE AS BEFORE.

4SPLICE WIRES USING SPLICE CLIPS AND ROSIN CORE

SOLDER. WRAP EACH SPLICE TO INSULATE.

5WRAP WITH MYLAR AND DRAIN (UNINSULATED) WIRE.

4COVER SPLICE WITH TAPE TO INSULATE

FROM OTHER WIRES.

5RETWIST AS BEFORE AND TAPE WITH

ELECTRICAL TAPE AND HOLD IN PLACE.

8-24-94

RS 22186

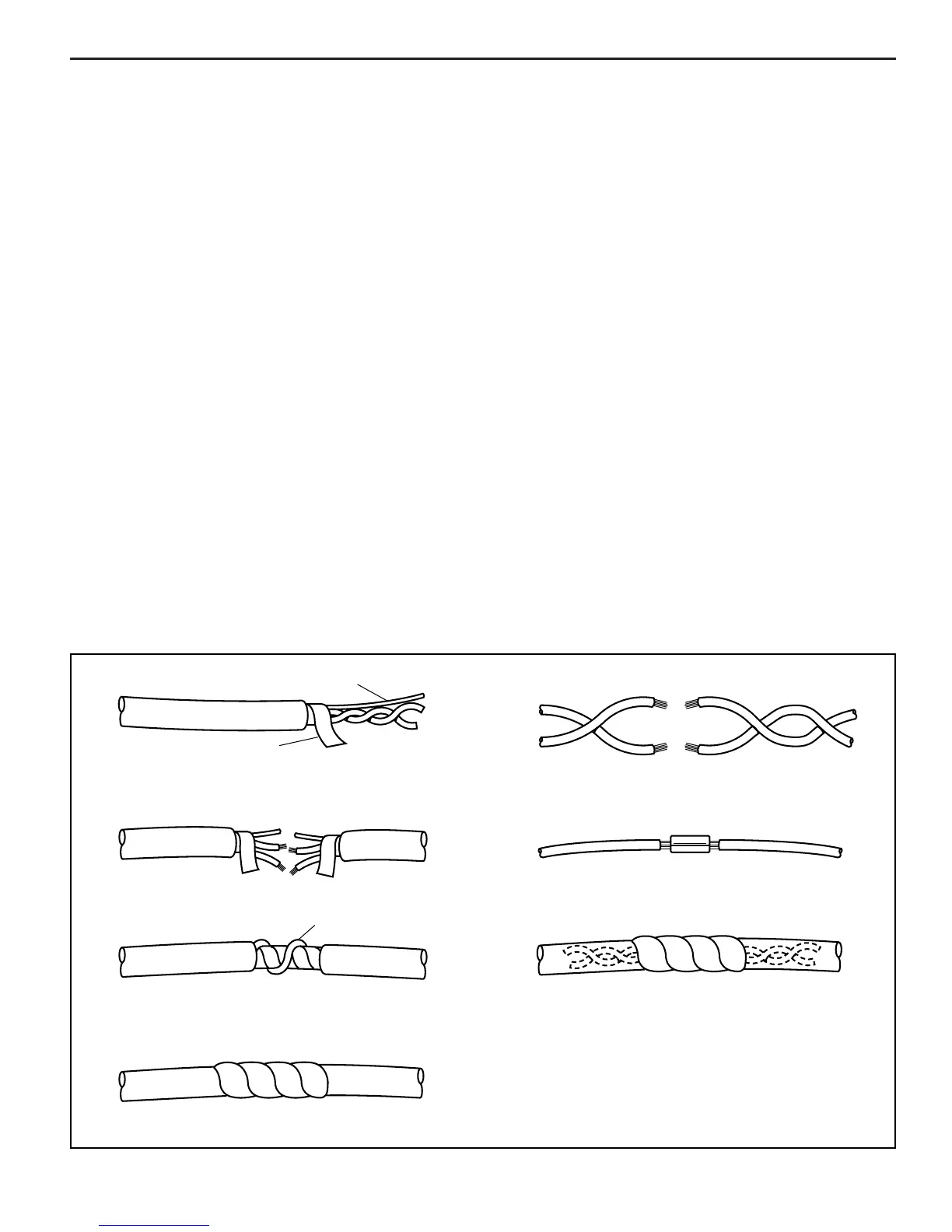

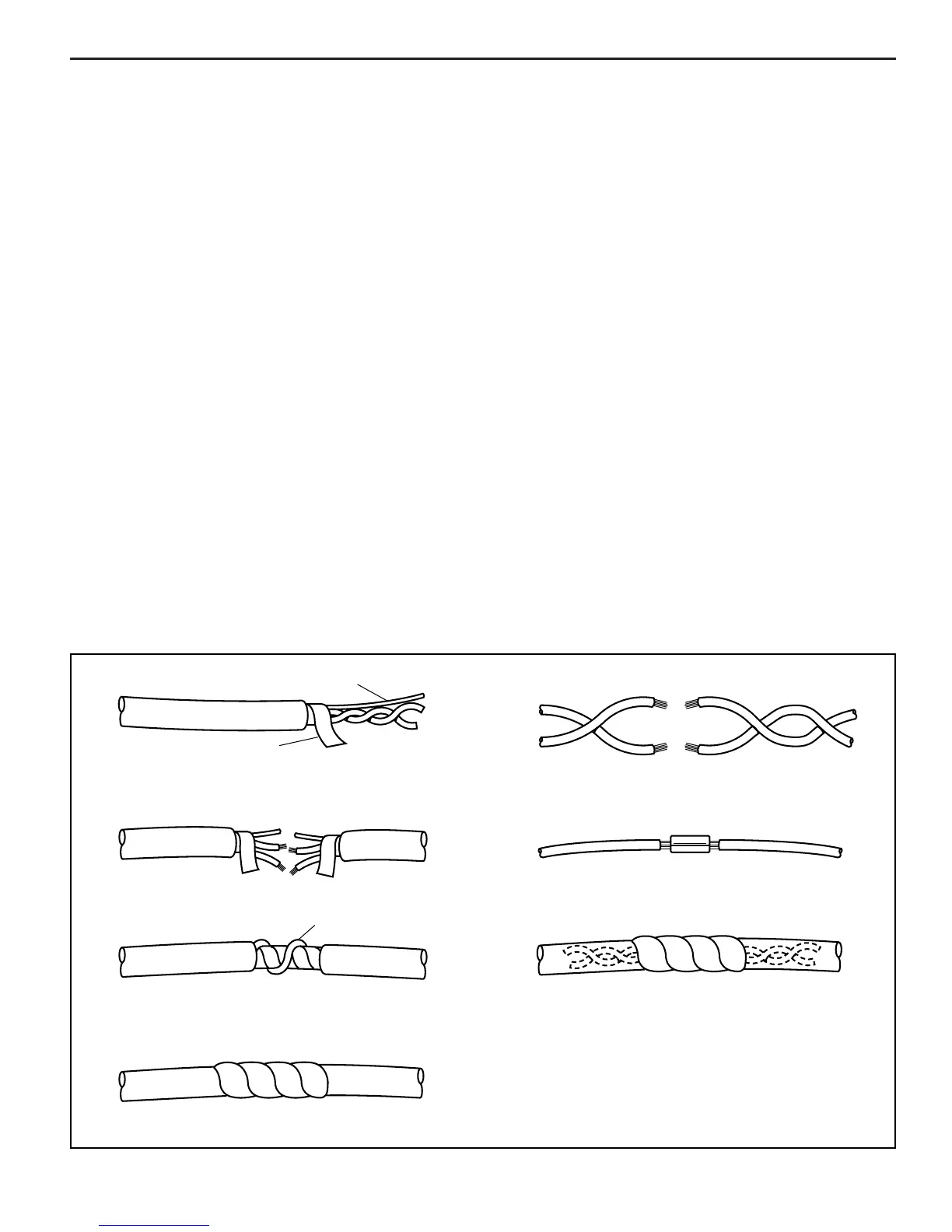

Figure 1-5 - Wiring Harness Repair

•

Tendency for connectors to come apart due to vibration

and/or temperature cycling.

•

Terminals not fully seated in the connector body.

•

Inadequate terminal crimps to the wire.

On-Board Service

Wiring Harness Service

Figure 1-5

Wiring harnesses should be replaced with proper part

number harnesses. When wires are spliced into a harness,

use the same gauge wire with high temperature insulation

only.

With the low current and voltage levels found in the

system, it is important that the best possible bond be

made at all wire splices by soldering the splices as shown

in Figure 1-5.

Use care when probing a connector or replacing a connector

terminal. It is possible to short between opposite terminals.

If this happens, certain components can be damaged.

Always use jumper wires with the corresponding mating

terminals between connectors for circuit checking. NEVER

probe through connector seals, wire insulation, secondary

ignition wires, boots, nipples or covers. Microscopic

damage or holes may result in water intrusion, corrosion

and/or component failure.

Diagnosis

The diagnostic tables and functional checks in this manual

are designed to locate a faulty circuit or component through

logic based on the process of elimination. The tables are

prepared with the requirement that the system functioned

correctly at the time of assembly and that there are no

multiple failures.

Engine control circuits contain many special design features

not found in standard vehicle wiring. Environmental

protection is used extensively to protect electrical contacts.

Proper splicing methods must be used when necessary.

The proper operation of low amperage input/output circuits

depend upon good continuity between circuit connectors. It

is important before component replacement and/or during

normal troubleshooting procedures that a visual inspection

of any questionable mating connector is performed. Mating

surfaces should be properly formed, clean and likely to

make proper contact. Some typical causes of connector

problems are listed below:

•

Improperly formed contacts and/or connector

housing.

•

Damaged contacts or housing due to improper

engagement.

•

Corrosion, sealer or other contaminants on the contact

mating surfaces.

•

Incomplete mating of the connector halves during

initial assembly or during subsequent troubleshooting

procedures.

Loading...

Loading...