THE

SPREAD

SYSTEM

Thl'

(Oller:..

lhl'IllSl'lvcs

p~rfonll

till'

ViI

"I

fUlll"!

iOI1

Till.'

spre,uJ

sysh~111

works

in

coojundioo

with

the

-

lilm pat:k

to

proct:$."

the

negative ilnd pO$itivc.

Thl."syskm.

Ibr

our

purposes.

\,,'an

be

considered

to

~Onslst

of

the roilers. the edge

control

bar and

slide

blod

assembly

:.lor.!

the

door

~pring

(!>Cl"

-

Figure

::!4t

-

In

Figures

2~1

through

2~3.

the

film pat:k

IS

shown

I();hj~

in

the

camera. The

:H:tion

of

the

pressnrl;!

pwte

kc~ps

tht!

top

negative

forced

agai.nst

the

window

of

the

p<lck.

The door spring, to turn,

ket':ps

the

entire

pack forced against

the

body

-

-

Olssembly, Tlnls.

the

pressure

plate

and

the

door

spring workmg together, guarantee thar

the

neg-

Siitive

being

exposed

is

at

tbe

appropriate

focaJ

plane.

The edge

conlrol

bar and slide block assembly

serve 'to funnel

the

yellow tab through

the

-

rollers. The slide block acts

as

a

movable

plat-

fonn

for

the edge controJ bar whleh has

both

-

lateral

and

vertical

movement.

The

bent

fingers

on

the

bar

catch

the

tab

and

direct

the

film

through the roUefS

in

a

straight

Jine.

(However.

they cannot

fOtaUy

prevent

bad

spreads caused

-

by film being pulled

out

of

the

camera

at extreme

angles.)

The

play in the edge control

bar

aJJows

the

assembly

to

move

with

the

tab

and

thus

avoids

any ripping

of

mm,

Note

that

the

top

roner

has

a shoulder

at

either

end.

They

provide

for a

separation

which

pennits the

tab

to

fit

through the rollers. When the rollers

are

freed

-

for

cleaning,

the

sliding block

moves

the

edge

bar

back

out

of

the

way.

-

-

-

-

-

-

-

of

evenly

dislributill~

thl'

d~vcIQrin!!jdl)

hl'-

tween

the

ne~livt'

and

(he

positiv

....

Ill,,' film

.,:;scmbly is

dt.'~ignl'd

so

tllil' Ih\.'

",idl>:'

or

tin: neg-

ative

;.mrJ

posilive arl' tightly l'Ompn:ssl'rJ hy

lhl'

r.Jils

while

Ihey

"rc

passing

through

rhe

roll~'rs"

Thi:s

prevents

lill.'

jelly

from

bl'ing

SqUt.'t.'l'l'U

out

lbe

sides.

or

(he

:.I)L~mbly

hel'

Figure

'::~5).

When

th~

jeJly

ha:.;

been

i!v~nly

s.pre~d

over

!he ,,'ntirl'

lenglh

of

the

positive,

the

~ap

in

the

roll\'r

j.,.

in-

creased

by

the

tr"ps

on

the

film

.,ss~mbl~,

This

permits"t~

excess jelly

to

be

trapped in

Ih~

p<Jpt:f

mask.

Otherwisc.

the

deveJopingjelly

would

be

squeezed

completely

out

of

the

pic-tuft! a:>\l'mbly

and

would

be

deposited

in

the

roUcr "re;L

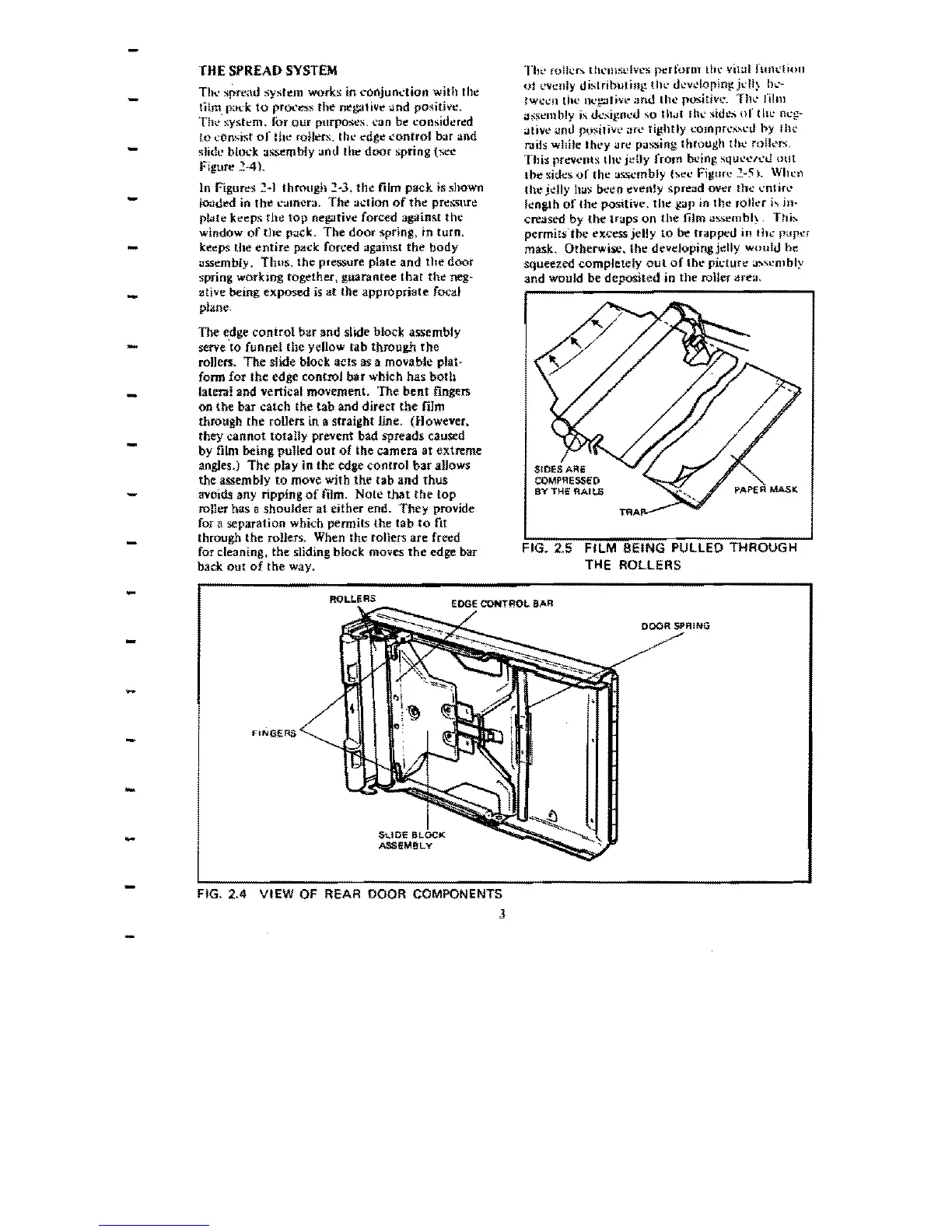

SIDES ARE

COMPRESSED

BY

THE RAILS

rnA

PAPER

MASK

FIG. 2.5

FILM

BEING

PULLEO THROUGH

THE ROLLERS

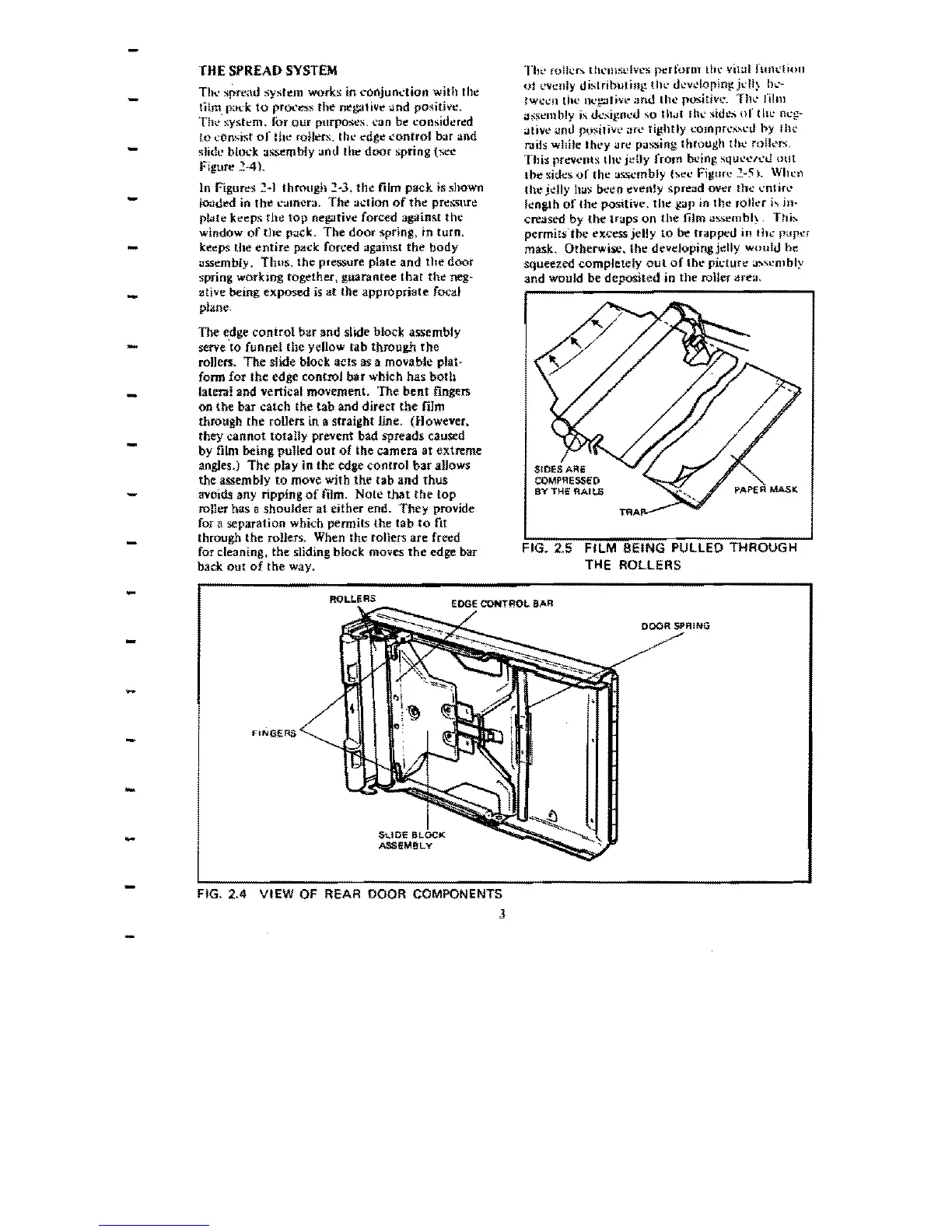

ROLLERS

eDGE CONTROL

8AR

FINGERS

DOOR

,*:"'00

FIG. 2.4

VI

EW

OF REAR DOOR COMPONENTS

J

Loading...

Loading...