40 EGW06-PCPEG-20140813

TM

TM

Section IV: Installation

Sizing:

• The lines must be sized and routed so that oil is carried through the system. Using smaller lines than recommended

will give excessive pressure drops, resulting in reduced capacity and increased power consumption. Oversized lines

could result in an oil ow problem within the system and possible compressor damage.

• Excessive pressure drops in the liquid line may cause ashing of the refrigerant and a loss of a liquid seal at the

expansion valve inlet. A reduction in capacity may then occur because the presence of gaseous refrigerant will

partially block the expansion valve. Using hot gas and liquid line sizes recommended in the Air Cooled Condenser

section for these units and the proper system refrigerant charge will prevent this problem.

• Discharge lines should be designed to prevent condensed refrigerant and oil from draining back to the compressor

during OFF cycles. Use the following guidelines.

◦ The highest point in the discharge line should be above the highest point in the condenser coil.

◦ The hot gas line should loop toward the oor if the condenser is located above the PoolComPak™ unit, especially

if the hot gas riser is long.

• For refrigerant line sizing for an Air Cooled Condenser (ACC) where the lineset length is less than 100 feet or the

ACC location is less than 50 feet higher or 20 feet lower than the unit, use the below Table 4-3.

• ACC line lengths beyond the above limits will void warranty unless written approval is obtained from the

factory PRIOR to installation and startup.

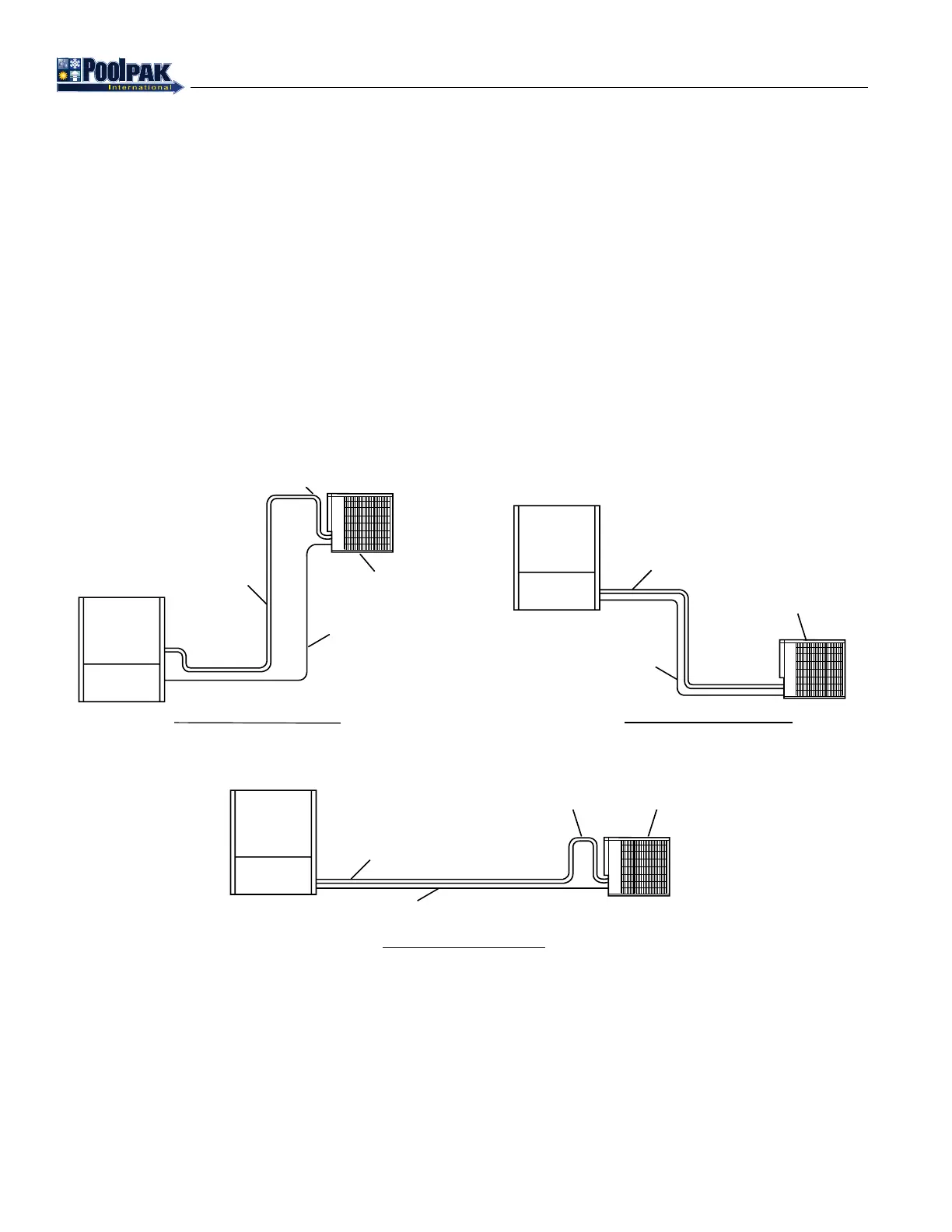

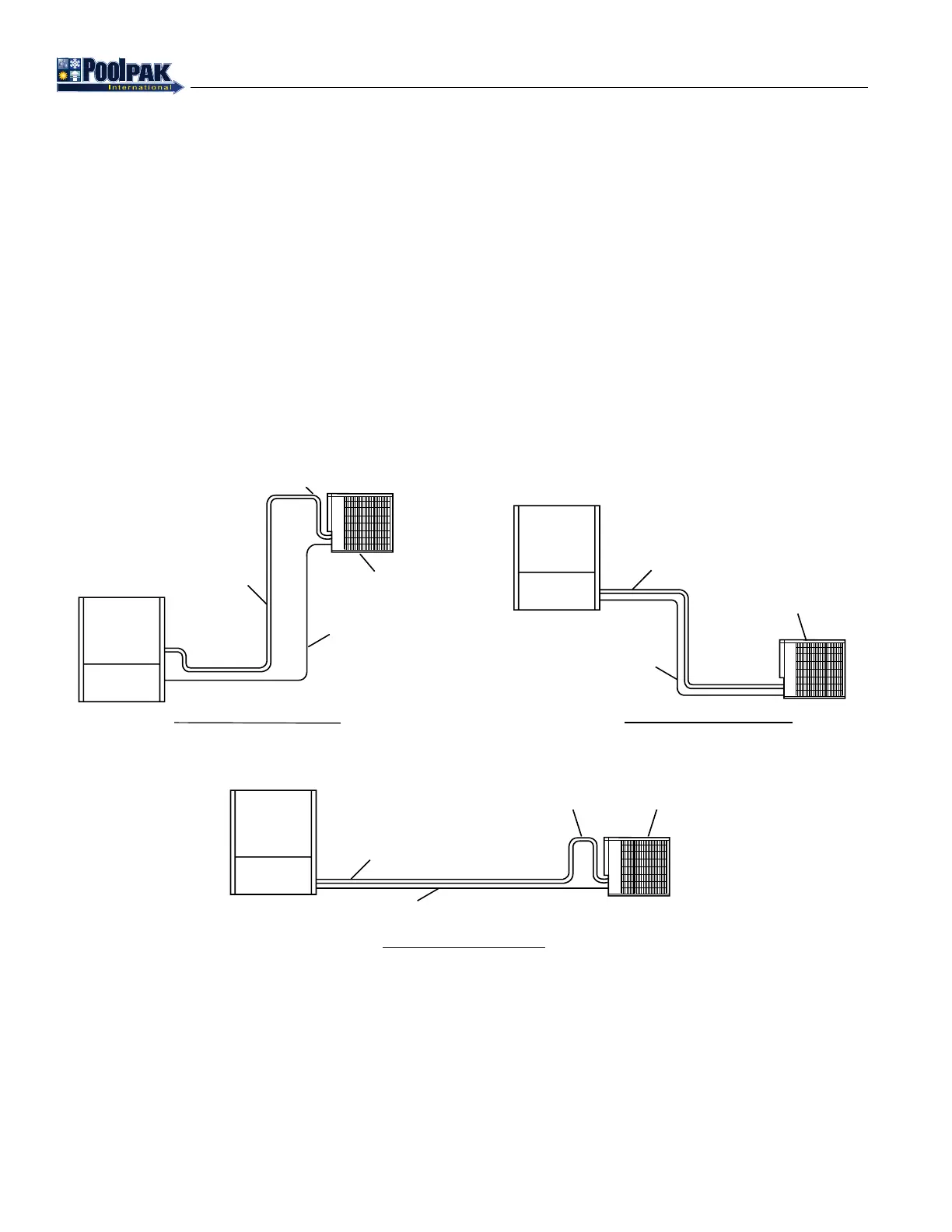

Figure 4-14. ACC Refrigerant Piping

PCP_EG_ACCPiping_20140122.eps

DISCHARGE LINE

Pitch in

Direction of

refrigerant flow

LIQUID LINE

AIR-COOLED

CONDENSER

DISCHARGE LINE

Pitch in

Direction of

refrigerant flow

LIQUID LINE

AIR-COOLED

CONDENSER

TOP OF

CONDENSER

COIL

DISCHARGE LINE

LIQUID LINE

ACC LOCATED ABOVE

AIR-COOLED

CONDENSER

CONDENSER COIL

Pitch in

Direction of

refrigerant flow

ACC LOCATED BELOW

ACC LOCATED LEVEL

Loading...

Loading...