34 PowerBox-Systems − World Leaders in RC Power Supply Systems

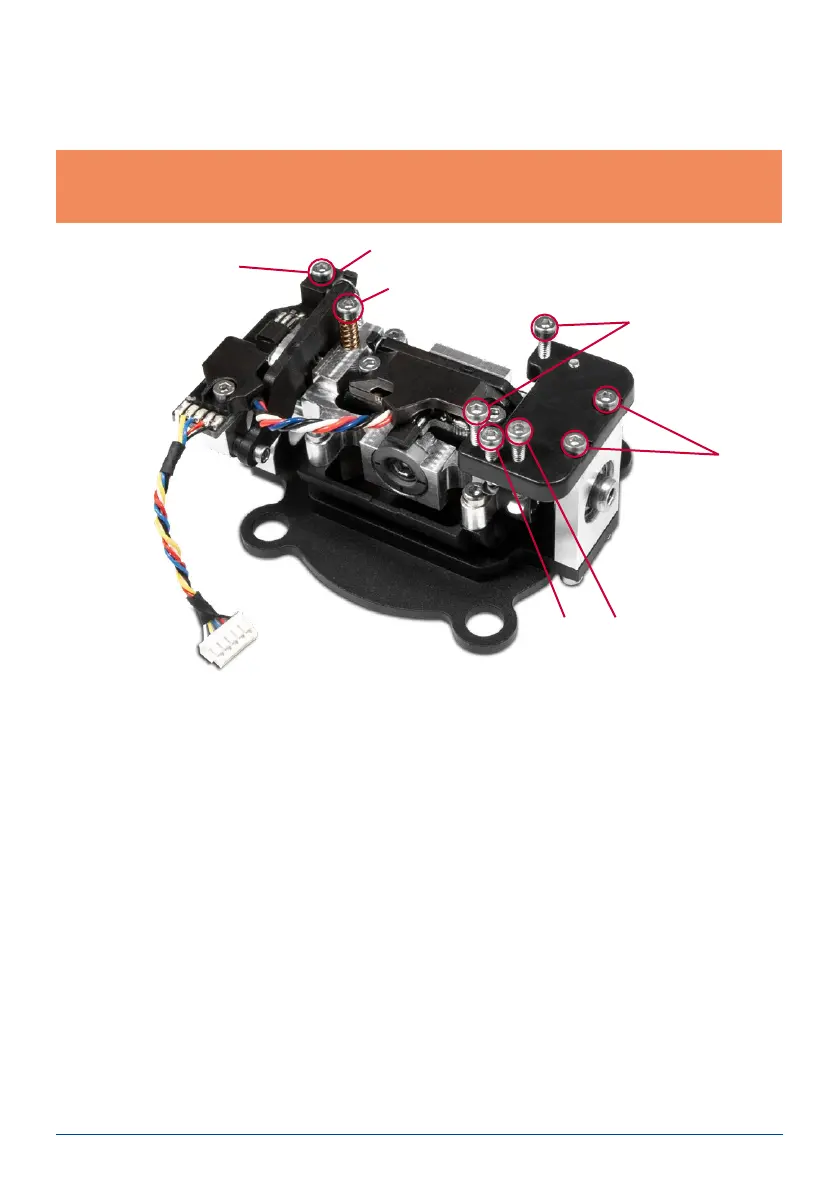

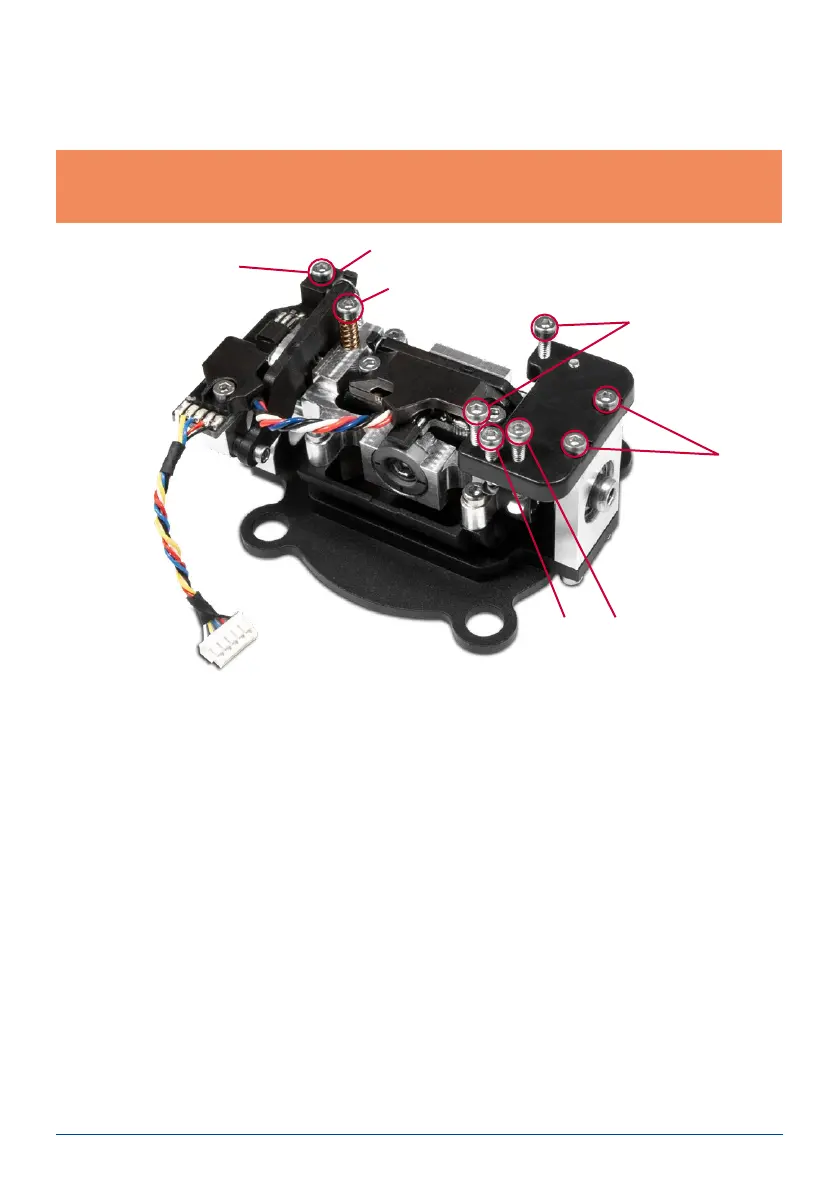

c) Adjusting the tension of the primary stick centring springs

On the screws 1 and 2, the centring spring tension can be adjusted for the respective axis. Tightening the screw

further increases the spring tension. If you nd it impossible to set your preferred spring tension, we can supply

a range of stronger springs.

d) Adjusting the throttle ratchet and brake

The hardness of the throttle ratchet can be adjusted using screw 3. Screw 4 adjusts the friction brake.

e) Adjusting the throttle travel

The travel of the throttle stick on the CORE is adjustable. This is useful for 3D pilots in particular, as it enables

them to set a mechanical limit on throttle travel. Adjustment is carried out by tightening screws 5. The throttle

travel can also be set up asymmetrically. Once you have set the travel of the throttle stick to meet your require-

ments, it is essential to re-calibrate that function.

f) Switching modes

As already mentioned, the software has no modes, but naturally the hardware must correspond to your preferred

mode.

If you wish to change the factory default mode, rst undo screws 6 from the ratchet plate, then install the ratchet

plate on the other primary stick unit, as an exact mirror-image of the original installation. Tighten the retaining

screws, pressing the plate towards the center of the transmitter.

The next step is to re-install the spring blocker (8): remove screw 7. The screw with the spring can immediately

be installed again on the other side.

To re-install the spring blocker, move the stick fully to its end-point, t the spring blocker pin under the spring lever,

then tighten the spring blocker screw.

Note: if you tighten the screw too far, you may nd that the lower spring tensioner partially moves out of its

guide. You can correct this by moving the stick fully to one side, at the same time pressing the spring tensio-

ner back into its guide using a small screwdriver.

6

5

43

1

2 / 7

8

Loading...

Loading...