page no. 12 of 40

VPx Range Users, Installation & Servicing Instructions Doc Ref M205 issue 1.2 Nov 2018.

Type B22 Installation (these refer to section 2.2 of

these instructions)

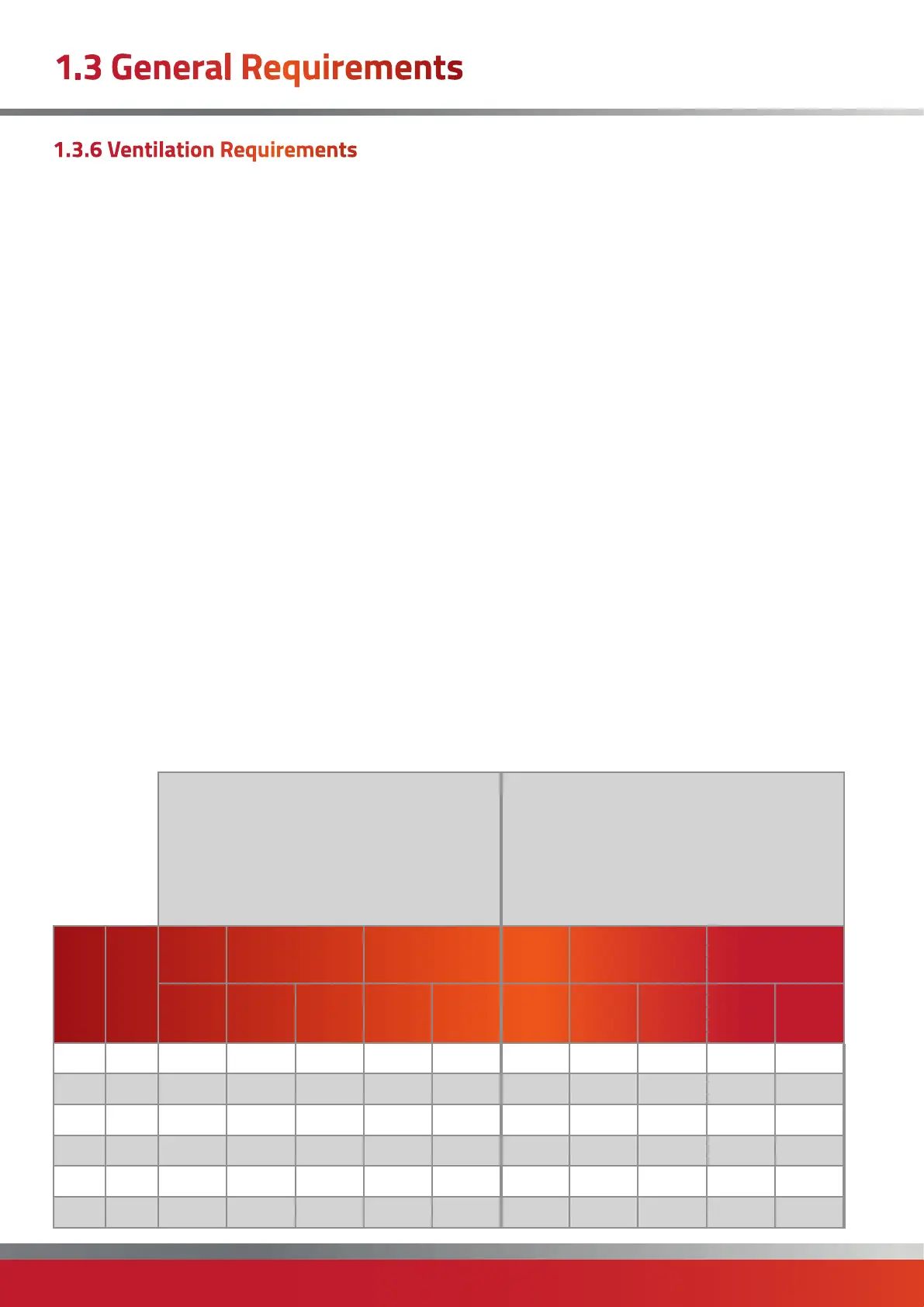

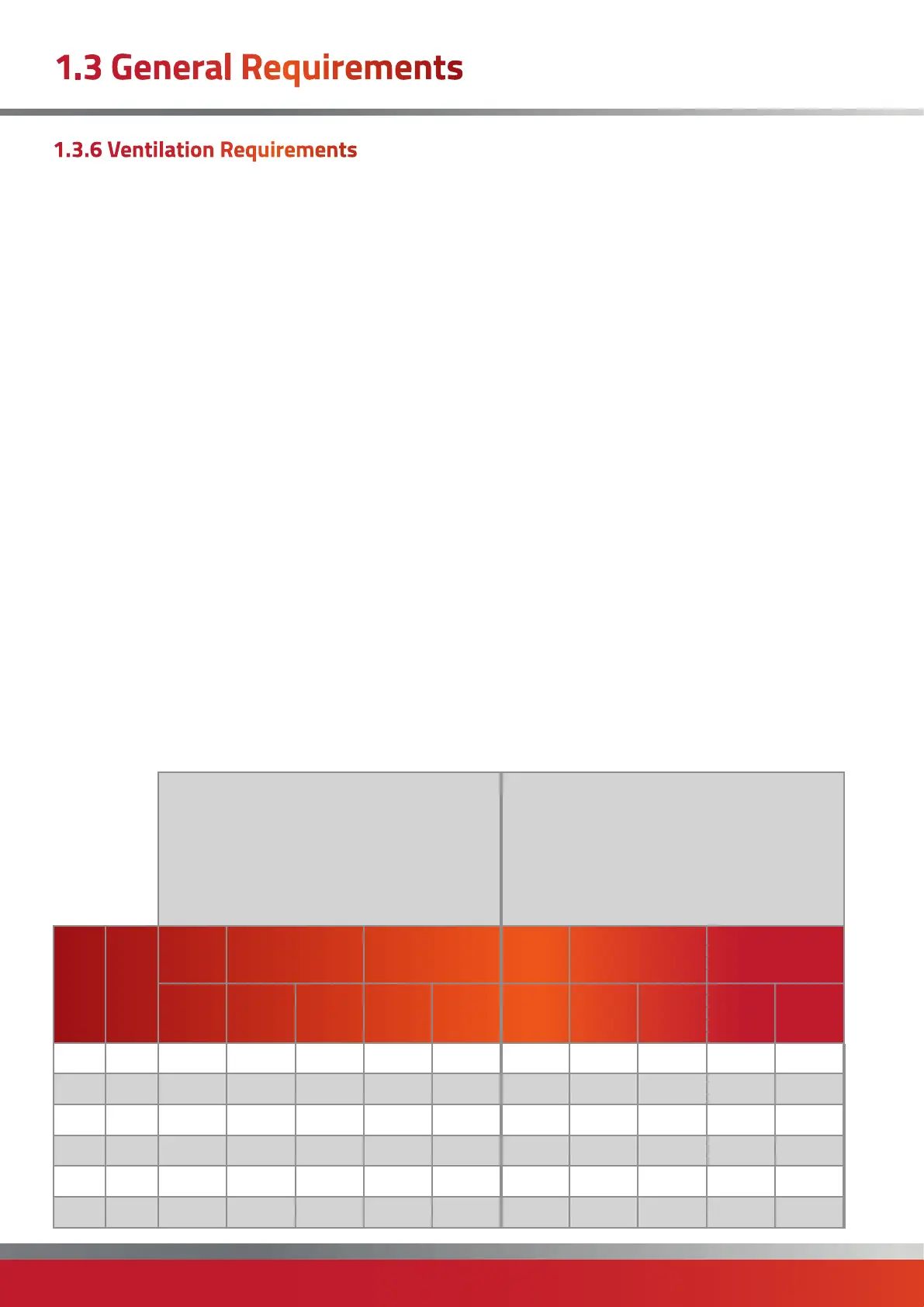

Air vents shall be permanently open.

In all cases figures are per heater installed.

For multi heater installations the appropriate

values for each heater must be added together

Type C

12 or C32 Installation (these refer to section 2.2

of these instructions)

Air vents shall be permanently open.

Figures are for heaters in plant rooms or

enclosures ONLY

In all cases figures are per heater installed.

For multi heater installations the appropriate

values for each heater must be added together.

VPx

Input

kW

In the

heated

space

In a plant room,

ventilation to

outside

In an enclosure,

ventilation to

outside

In the

heated

space

Ventilation is to a

room or internal

space

Ventilation is to a

outside air

Low level

grille.

Free area

cm²

Low level

grille.

Free area

cm²

High level

grille.

Free area

cm²

Low level

grille.

Free area

cm²

High level

grille.

Free area

cm²

Free area

grille cm²

Low level

grille.

Free area

cm²

High level

grille.

Free area

cm²

Low level

grille.

Free area

cm²

High level

grille.

Free area

cm²

35 36.5 73.0 146.0 73.0 365.0 182.5 n/a 365.0 365.0 182.5 182.5

50 54.5 109.0 218.0 109.0 545.0 272.5 n/a 545.0 545.0 272.5 272.5

70 76.5 153.0 306.0 153.0 765.0 382.5 n/a 765.0 765.0 382.5 382.5

90 97.5 195.0 390.0 195.0 975.0 487.5 n/a 975.0

975.0 487.5 487.5

120 127.0 254.0 508.0 254.0 1270.0 635.0 n/a 1270.0 1270.0 635.0 635.0

140 146.0 292.0 584.0 292.0 1460.0 730.0 n/a 1460.0 1460.0 730.0 730.0

1.3.6 Ventilation Requirements

Type B flued installations.

Where VPx heaters are installed within the heated space

(ie not in a plant room or an enclosure) and having a

building design air change rate of greater than 0.5/h,

additional provision for ventilation is not required.

If the building design air change rate is less than 0.5/h,

additional provision for natural or mechanical ventilation

is required. These being:

• Natural Ventilation:

Grilles having a free area of at least 2cm² per kW of rated

heat input shall be provided at low level i.e. below the level

of the heater flue connection.

• Mechanical Ventilation:

Must ensure that the space air change rate is at least

0.5/h, must be of the ‘input’ type and interlocked to

ensure the heaters cannot work if the input system is not

working.

Type B flued installations.

Where VPx heaters are installed in a plant room or

an enclosure (i.e. not within the heated space) having

combustion air drawn directly from the room and

connected to a flue that evacuates the products of

combustion directly from the room additional provision

for natural or mechanical ventilation is required.

These being:

• Natural Ventilation:

There must be permanent air vents communicating

directly with the outside air, at high level and at low level.

Plant Rooms

Low level (inlet) 4cm²/kw of total rated net heat input

High level (outlet) 2cm²/kw of total rated net heat input

Enclosures

Low level (inlet) 10cm²/kw of total rated net heat input

High level (outlet) 5cm²/kw of total rated net heat input

• Mechanical Ventilation:

The minimum flow rate of ventilation shall be 4.14m³/h

per kilowatt of total rated heat input.

Type C flued installations.

Where VPx heaters are Installed within the heated

space (i.e. not in a plant room or an enclosure) having

combustion air ducted to the appliance and combustion

products ducted to the outside air, NO additional

provision for the supply of either combustion air or for

combustion products dilution or additional provision for

the supply of air is necessary.

Type C flued installations.

Where VPx heaters are installed in a plant room or

an enclosure (i.e. not within the heated space) having

combustion air ducted to the appliance and combustion

products ducted to the outside, air vents shall be

provided and be permanently open.

• To room or internal space

Low level (inlet) 10cm²/kw of total rated net heat input

High level (outlet) 10cm²/kw of total rated net heat input

• Direct to outside air

Low level (inlet) 5cm²/kw of total rated net heat input

High level (outlet) 5cm²/kw of total rated net heat input.

1.3 General Requirements

Loading...

Loading...