page no. 19 of 40

VPx Range Users, Installation & Servicing Instructions Doc Ref M205 issue 1.2 Nov 2018.

2.4.1. Electrical Connections

Warning: THIS APPLIANCE MUST BE

EARTHED.

Warning: Lockout reset is by a switched

Neutral to the controls in the heater.

Warning: Wiring external to the unit must be

carried out by an appropriately qualified

person to current IEE regulations for

Electrical Installations and any local regulations which

apply.

The local electrical supply must be run to a point adjacent

to the heater and be suitably terminated to provide an

isolation point that will prevent remote activation of

the unit during servicing. Wiring should be completed in

flexible conduit.

The local electrical supply conditions must be compatible

with the electrical data given on the appliance data plate.

Heaters are for use with 230V, 1N, 50Hz supplies.

The method of connection to the main electricity supply

must:-

- facilitate the complete electrical isolation of the

heater(s) via a suitable fused isolator that will prevent

remote activation of the heater during servicing (see

section 2.4.5 for ratings).

- be in a readily accessible position adjacent to the

heater(s).

- serve only the heater(s).

- have a contact separation of at least 3mm in all poles.

See section 2.5 or the accompanying wiring diagram for

the heater electrical connections.

Reference must be made to Section 2.4.5 to ascertain

the electrical loading of the unit(s) being installed so that

cables of adequate cross-sectional area are used for

the electrical installation. The length of the conductors

between the cord anchorage and the terminals must be

such that the current carrying conductors become taut

before the earth conductor if the cable or cord slips out

of the cord anchorage. All external controls must be of an

approved type.

All units are fully prewired and only require final

connections for the incoming mains supply. Heaters not

supplied with inbuilt time and temperature controls will

also require completion of the external control circuit

(230V) via a room thermostat, time clock etc. and, if

applicable, the remote low level lockout reset see 2.4.5.

Note: To achieve maximum system efficiency it

is recommended that VPx units are controlled

by an MC200 or MC300 unit. Simple room

thermostat and thermostat/time clock control

systems will not provide optimum system efficiency and

fuel savings.

Wiring drawings and instructions are supplied with the

respective controller.

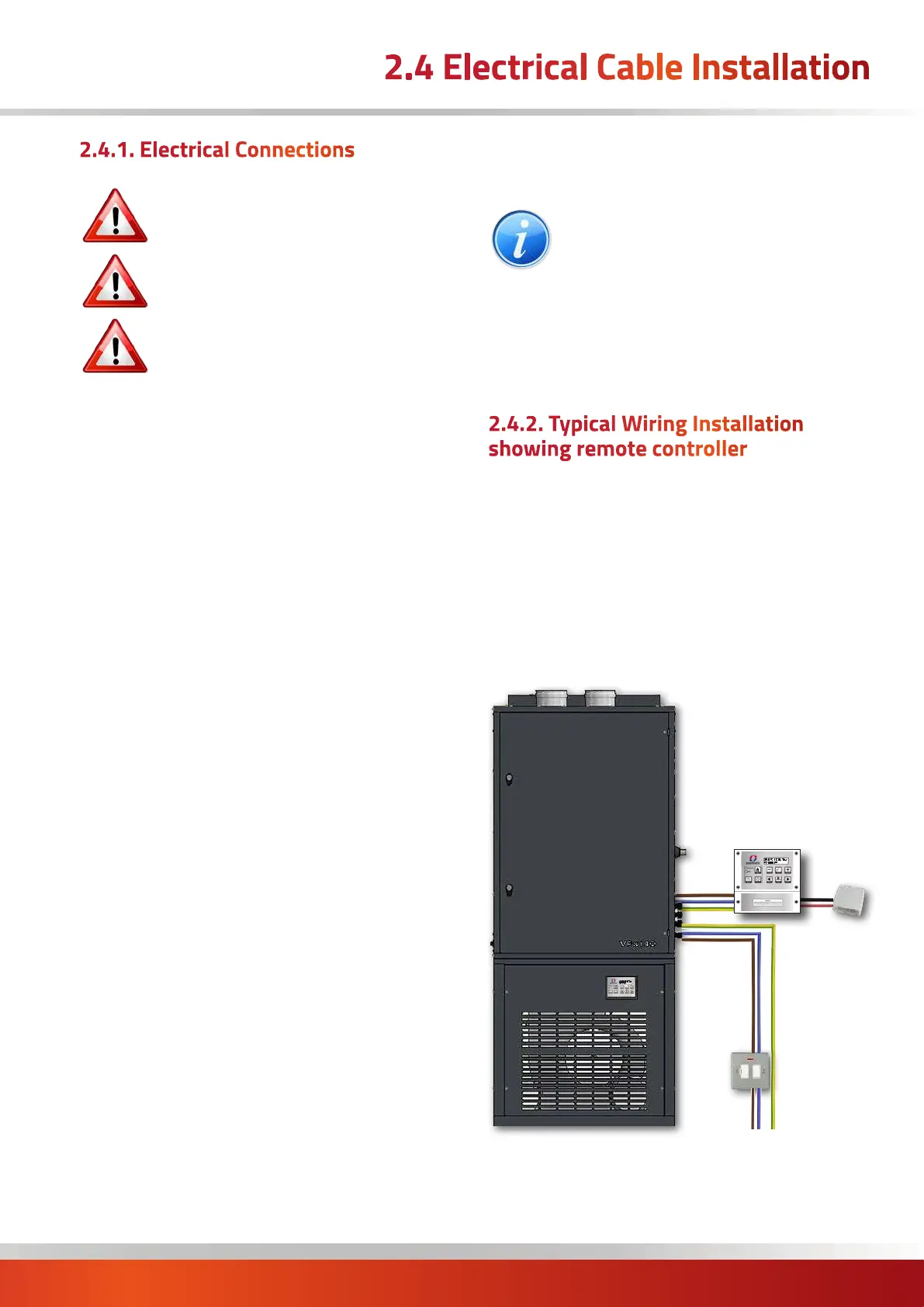

2.4.2. Typical Wiring Installation

showing remote controller

Key:

Mains supply = 2 core and earth

MC200 Controller = 8 core and earth

alt. MC300 Controller = 6 core screened + LNE

Optional MC200 sensor = Screened 2 core*

* (screen must be grounded only at the MC200, See

instructions supplied with controller for wiring sizing,

Max. 100m)

2.4 Electrical Cable Installation

Optional

Remote Controller

(MC200 shown)

Remote

Sensor

(optional)

Typical wiring

installation

Fused

Isolator

230V Supply shown

(415V option on 90-140)

Loading...

Loading...