13

The Programmable Logic Controller (PLC) and Smart Roll work together to give the desired output. Typically the pulses from a Smart Roll

are read by a PLC and converted to a speed output. This speed output can then be used by the PLC to create actions, such as shutting

down a conveyor due to an under speed condition.

If the roll is rotating too fast or the PLC is not sampling often enough, the output will not work as desired. There are specifications you

will need to know about your conveyor setup, PLC, and Smart Roll sensor. These specifications are belt speed, outside diameter including

lagging of the Smart Roll, pulses per revolution of the Smart Roll, sampling rate of the PLC and/or the minimum sample duration, and

power supplied to the sensor from the PLC.

The Smart Roll sensor has a maximum switching frequency of 20 Hz, or 20 pulses per second. Digital electronic equipment, such as a PLC,

takes intermittent sensor readings rather than continuously monitoring the sensor. If the switching of the sensor pulses is faster than the

sampling rate of the equipment, errors may occur. Marginal cases may have erroneous speed output from missed pulses, and extreme

cases may cause a complete lack of output.

WHAT IS A PULSE?

As the roll rotates, it opens and closes an electrical circuit to create pulses a preset number of times per revolution. One pulse is defined as

one complete on/off cycle.

Examples:

6 pulses per revolution the sensor creates 6 on/off cycles, or pulses for each revolution.

2 pulses per revolution the sensor creates 2 on/off cycles, or pulses for each revolution.

1 pulse per revolution the sensor creates 1 on/off cycles, or pulses for each revolution.

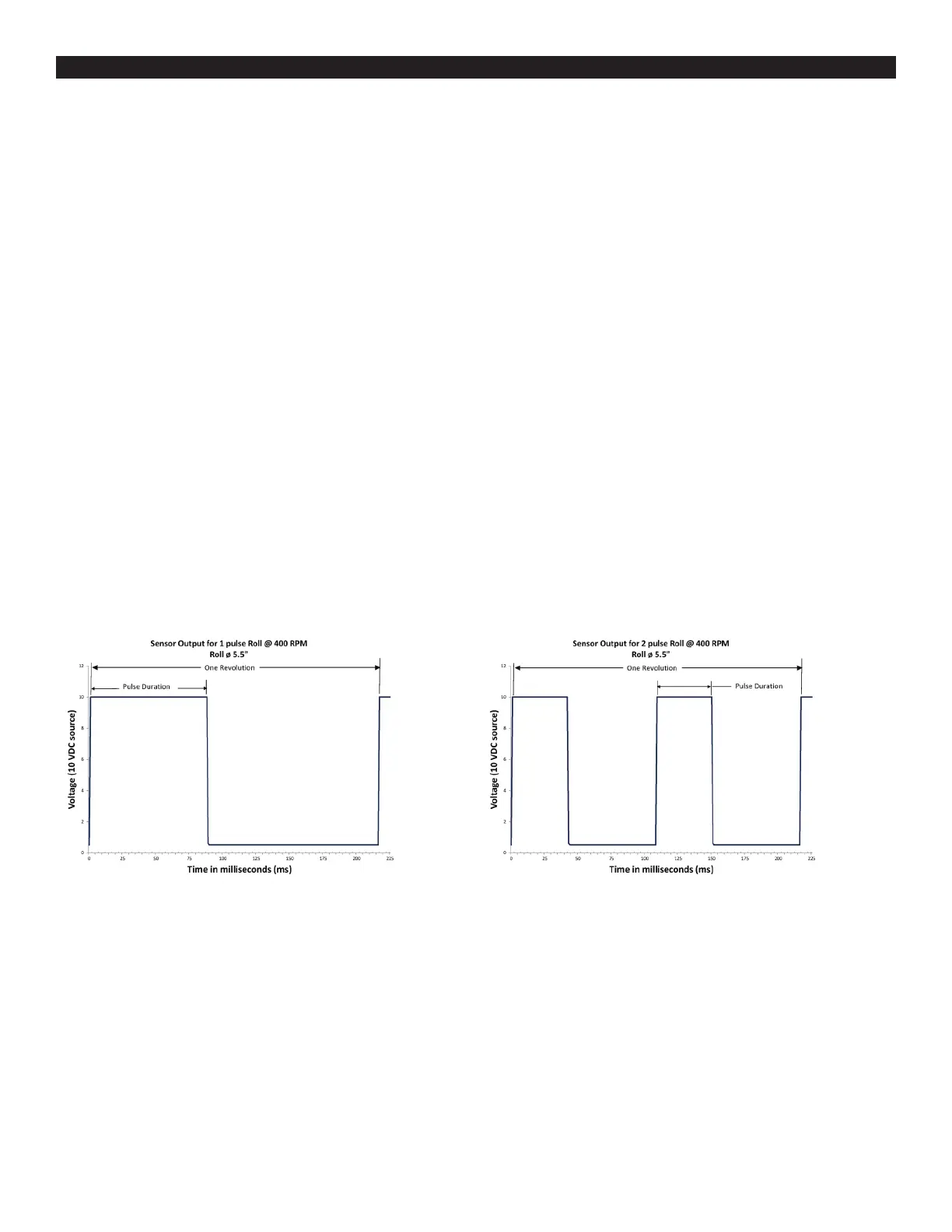

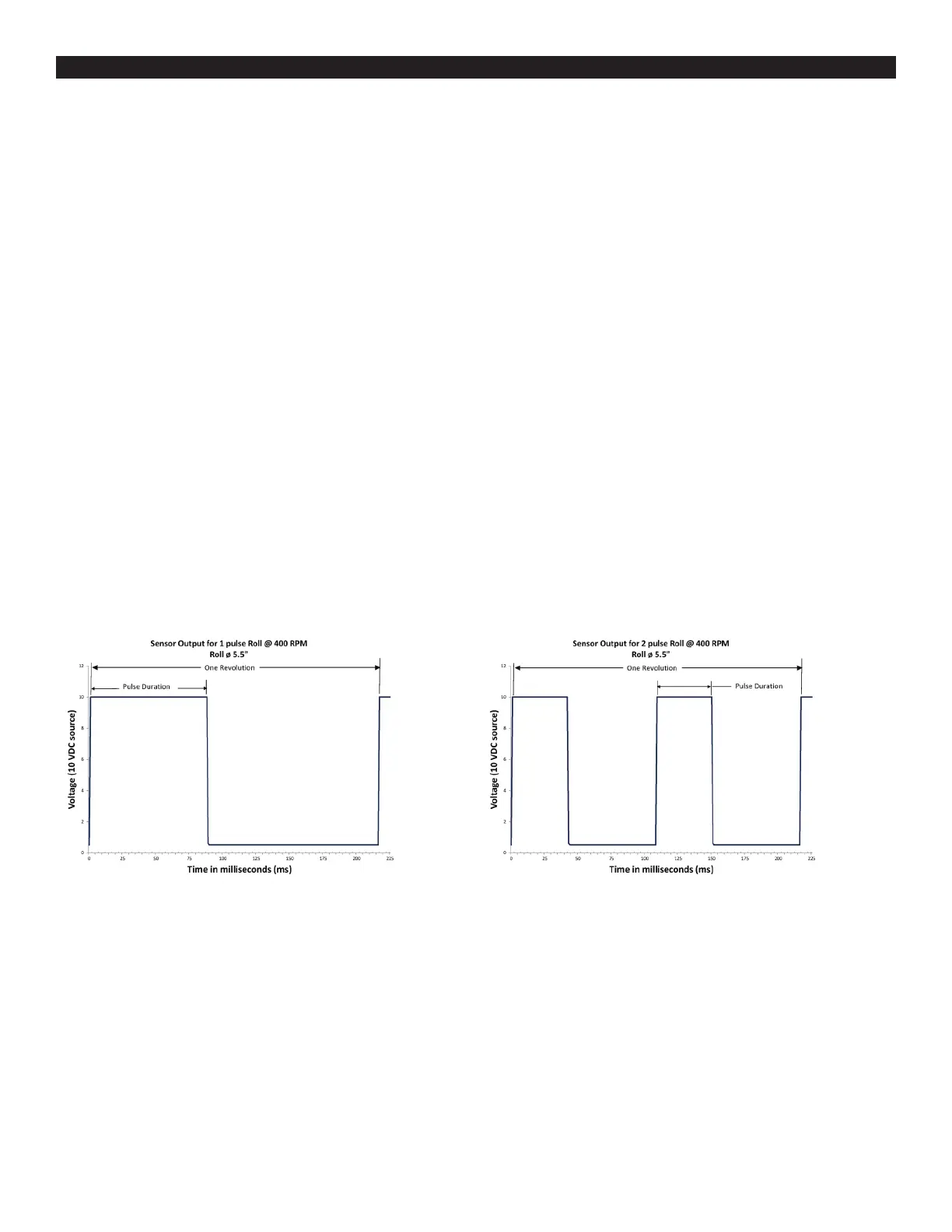

The 1 and 2 pulse options have fewer pulses and greater pulse duration, i.e. the pulse will have a greater width on the chart. Figures 6.1 and

6.2 show pulses using 400 feet per minute belt speed, Smart Roll part numbers SAD5CSRSB-1PL4, and SAD5CSRSB-2PL4 respectively.

WHAT IF THE PULSES ARE TOO FAST FOR MY ELECTRONICS?

USING A PLC

Figure 6.1: Example sensor output for a 1 pulse roll,

P/N SAD5CSRSB-1PL4

Figure 6.2: Example sensor output for a 2 pulse roll,

P/N SAD5CSRSB-2PL4

Loading...

Loading...