8

EN

Holdthedressingbrickrmlywithonehand(beingcarefulnottotouchthe

grinding wheel).

- Prolethegrindingwheelbyactivatingthemachineandgrindthegrindingwheel

untilyouobtainaproleliketheoneillustratedin.

- Switchthemachineoffonceyouhavenished.

29. SHARPENING THE DEPTH GAUGE

- Remove the dressing brick and put the chain in the vise.

- Center the cutter compared to the grinding wheel by turning the knobs (P29 and

P30).

- Keeping the arm tilted, adjust the grinding depth on the gauge by turning knob P31

.

- Sharpen the gauge following the instructions given in the “SHARPENING” section.

For this type of sharpening procedure, there is no difference between the right and

left cutters, therefore sharpen all the gauges one after the other.

- Check if the gauge depth is correct, using the template with the shape related to

the type of chain used . Please also consult the chain table, column F.

30. STOPPING AND SHUTTING DOWN

30.1 STOPPING

Turn the machine off by turning the switch to position “0” and unplug the power cable

from the mains.

30.2 SHUTTING DOWN

Onceyouhavenishedusingthemachine,disconnectitandcleanitthoroughly.

Store it in a dry and safe place, protected against dust and damp.

30.3 ROUTINE MAINTENANCE

Follow the instructions given in the “STOPPING” section before you start to

work on the machine.

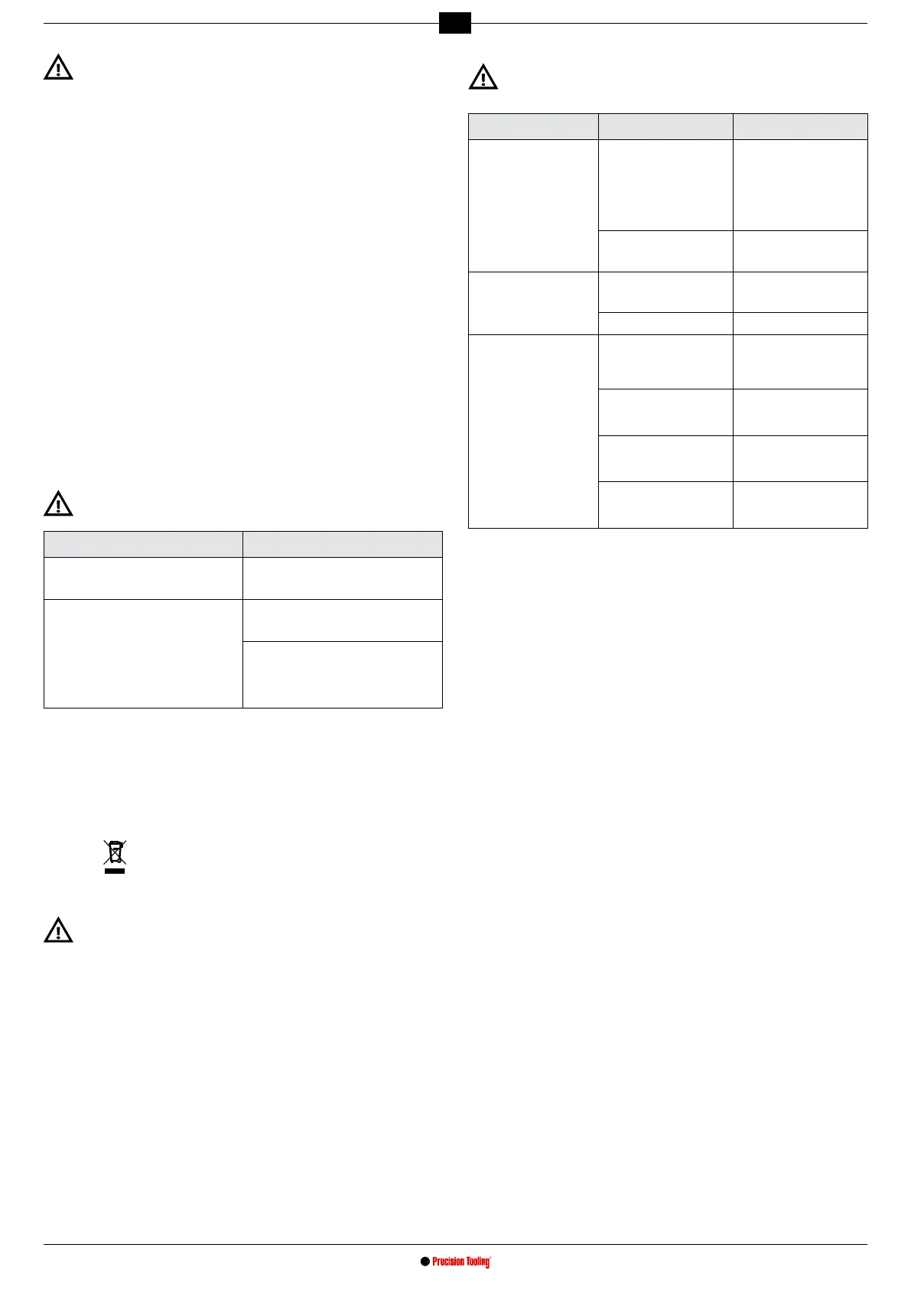

Maintenance frequency Operation

When the grinding wheel reaches a

minimum diameter of approximately

105 mm

Replace the grinding wheel.

40 hours

Clean the lamp carefully using a rag or a

cleaning brush.

Do not use compressed air.

Clean the grinder carefully using a rag or

a cleaning brush.

Clean the electric motor and the sliding

guides with caution.

Do not use compressed air.

30.4 HANDLING AND TRANSPORT

- If you need to transport the machine, take it off the bench or wall, dismantle the grind-

ing wheel and put all the parts in a packing box to protect them against impact.

30.5 DEMOLITION AND DISPOSAL

Themachineistobedemolishedbyqualiedpersonnelincompliancewithcurrent

laws in force in the country in which it is installed.

The symbol

(on the rating nameplate) points out that the product must not be

disposed of with normal household garbage. Contact an authorized tip or your dealer

for disposal instructions.

Before you scrap the machine, make it unusable by cutting the power supply

cable for example and make the parts safe, which could cause a source of

danger for children if they should play with the machine.

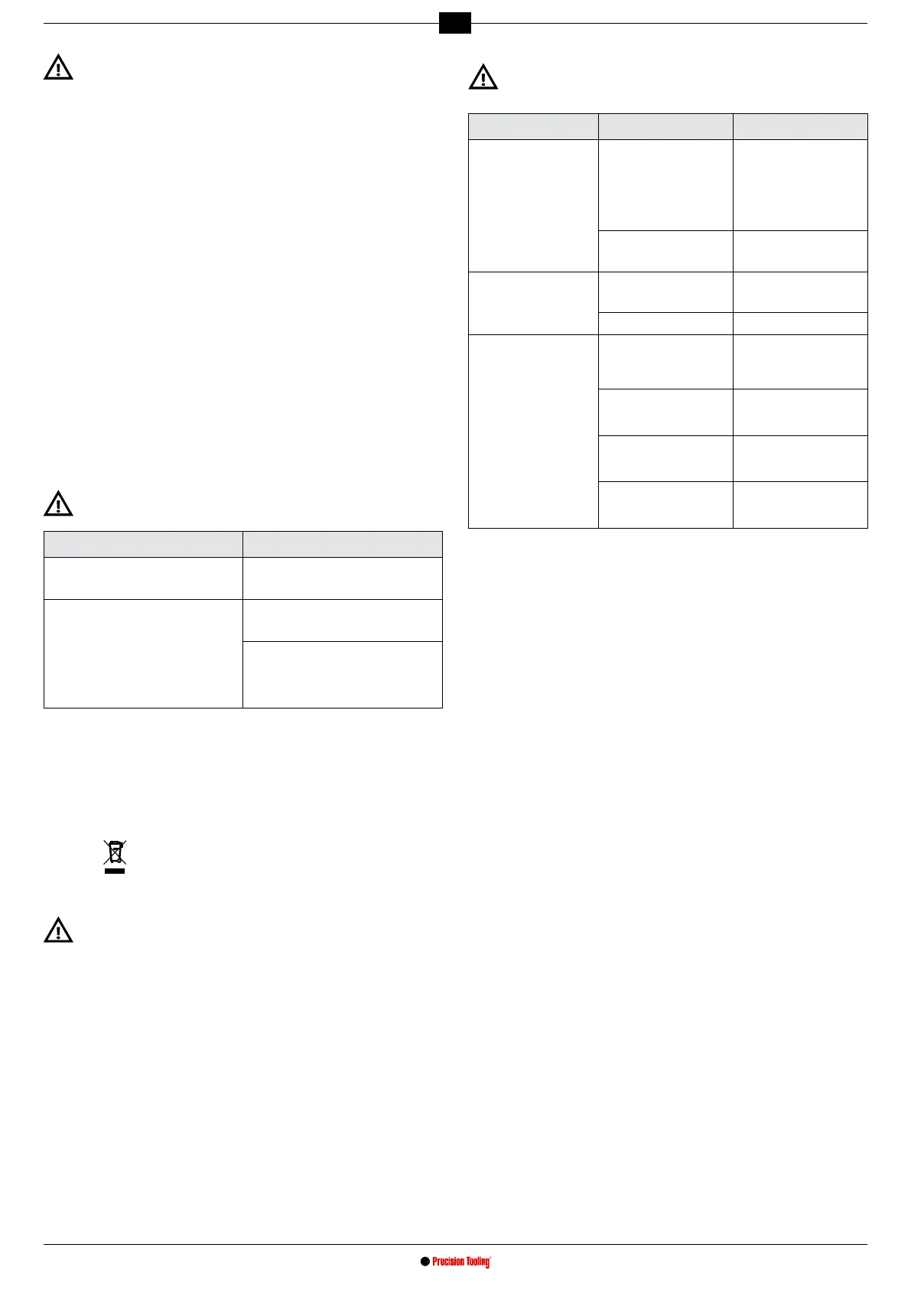

31. TROUBLE SHOOTING

Follow the instructions given in the “STOPPING” section before you start to

work on the machine.

Problem Probable cause Solution

The machine fails to

start when you switch on

(switch in pos. “1”).

One of the safety devices

of the system to which

the machine is connected

has tripped (fuse, circuit

breaker etc.)

Reset the safety device.

If the safety switch trips

again, do not use the

machine, but contact a

Skilled technician.

The machine is not plugged

into the mains properly.

Unplug and plug in again

properly.

The lamp fails to switch on

when the switch is turned

to position “1”.

The lamp is not screwed

properly into its seat.

Screw the lamp in place

properly.

The lamp has blown. Replace the lamp.

The machine vibrates

abnormally.

The grinder is not secured

correctly.

Check its attachment and,

if necessary, tighten the

securing screws correctly.

The arm-motor unit is not

secured correctly to the

base unit.

Tighten the related blocking

handle correctly.

The vise assembly is not

secured correctly to the

base unit.

Tighten the related blocking

handle correctly.

The grinding wheel is not

ttedcorrectly in itsseat

on the hub.

Dismantle the grinding

wheel, check its integrity

andtagaincorrectly.

- Contact a skilled technician if you are still unable to restore the correct operation

of the machine following the instructions given in the chart.

Loading...

Loading...