18 © 2016 Proceq SA

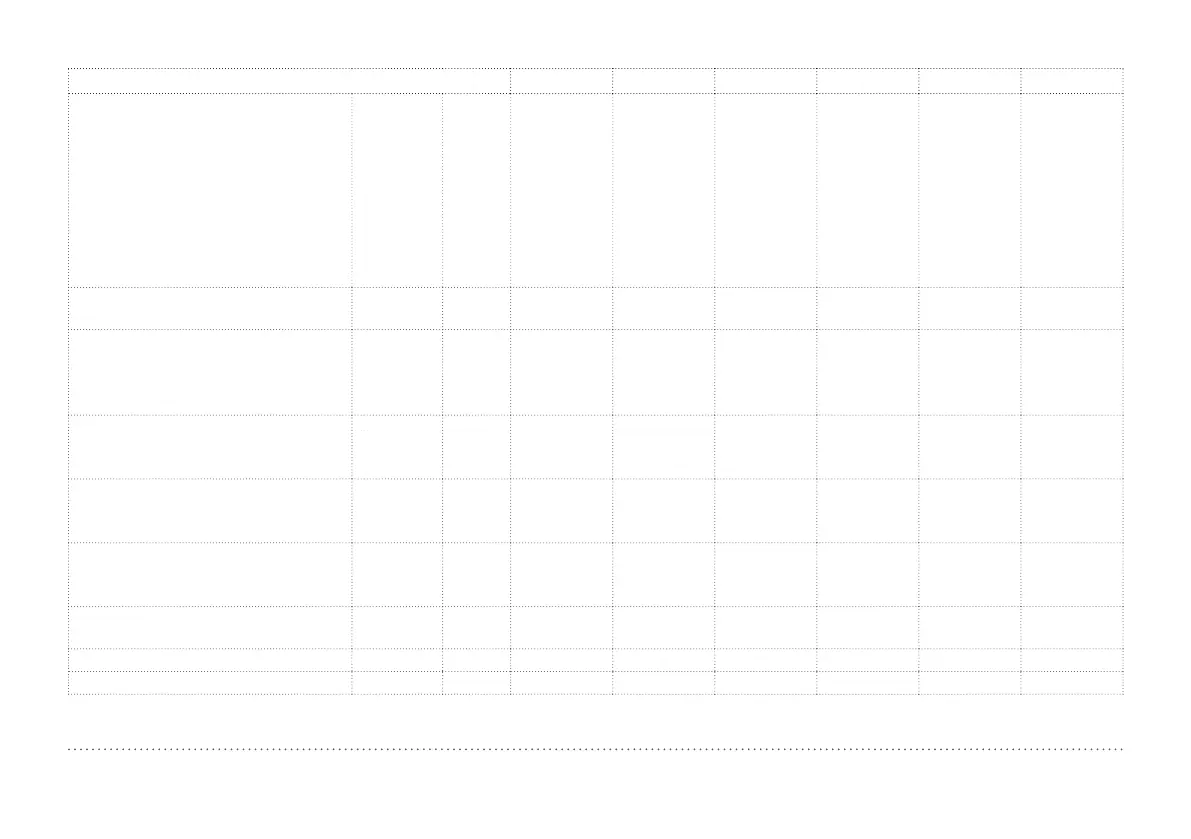

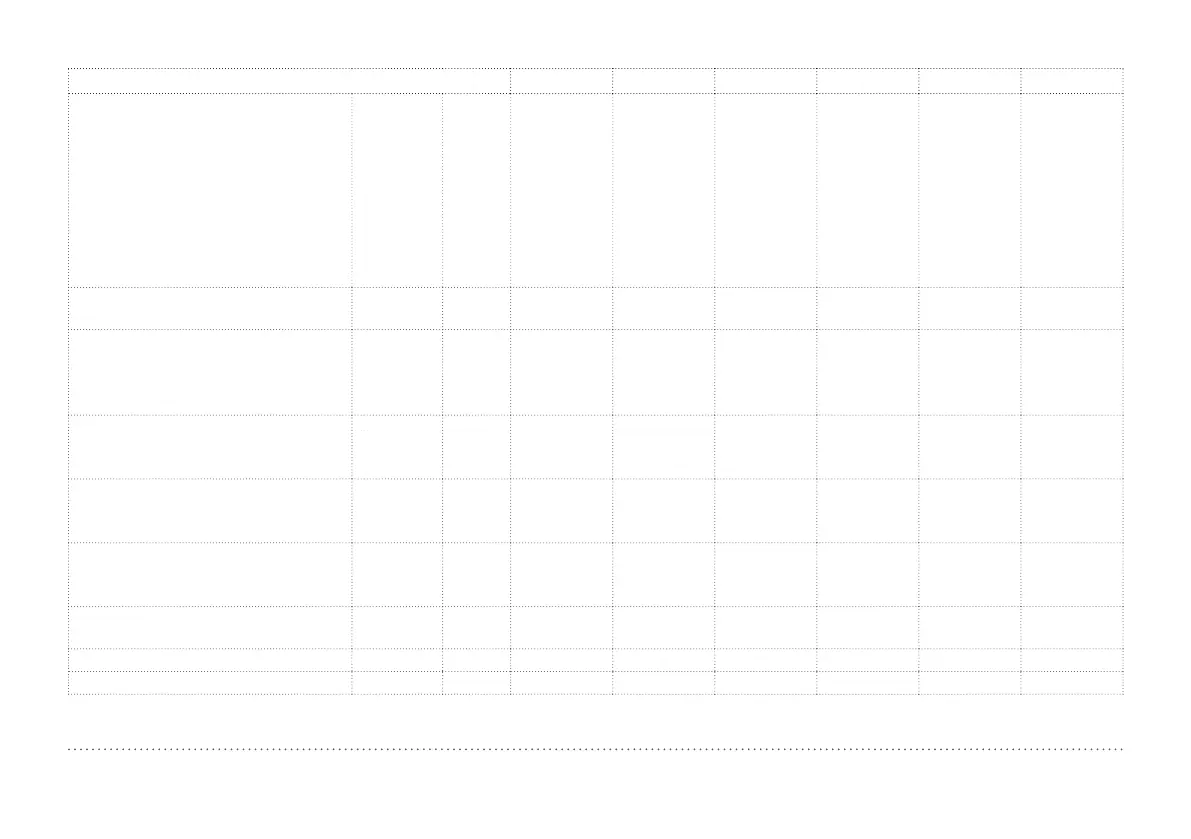

D/DC DL S E G C

Steel and cast steel

Vickers

Brinell

Rockwell

Shore

Rm N/mm²

HV

HB

HRB

HRC

HRA

HS

σ1

σ2

σ3

81-955

81-654

38-100

20-68

30-99

275-2194

616-1480

449-847

80-950

81-646

37-100

21-68

31-97

275-2297

614-1485

449-849

101-964

101-640

22-70

61-88

28-104

340-2194

615-1480

450-846

84-1211

83-686

20-72

61-88

29-103

283-2195

616-1479

448-849

90-646

48-100

305-2194

618-1478

450-847

81-1012

81-694

20-70

30-102

275-2194

615-1479

450-846

Cold work tool steel

Vickers

Rockwell

HV

HRC

80-900

21-67

80-905

21-67

104-924

22-68

82-1009

23-70

* 98-942

20-67

Stainless steel

Vickers

Brinell

Rockwell

HV

HB

HRB

HRC

85-802

85-655

46-102

20-62

* 119-934

105-656

70-104

21-64

88-668

87-661

49-102

20-64

* *

Cast iron lamellar graphite GG

Brinell

Vickers

Rockwell

HB

HV

HRC

90-664

90-698

21-59

* * * 92-326 *

Cast iron, nodular graphite GGG

Brinell

Vickers

Rockwell

HB

HV

HRC

95-686

96-724

21-60

* * * 127-364

19-37

*

Cast aluminium alloys

Brinell

Vickers

Rockwell

HB

HV

HRB

19-164

22-193

24-85

20-187

21-191

20-184

22-196

23-176

22-198

19-168

24-86

21-167

23-85

Copper/zinc alloys (brass)

Brinell

Rockwell

HB

HRB

40-173

14-95

* * * * *

CuAI/CuSn-alloys (bronze)

Brinell HB 60-290 * * * * *

Wrought copper alloys, low alloyed

Brinell HB 45-315 * * * * *

*Custom conversion curve / correlation

Table 2: Overview of Available Conversions

Loading...

Loading...