MAINTENANCE

BLAZER 980073 09/16/02

4-17

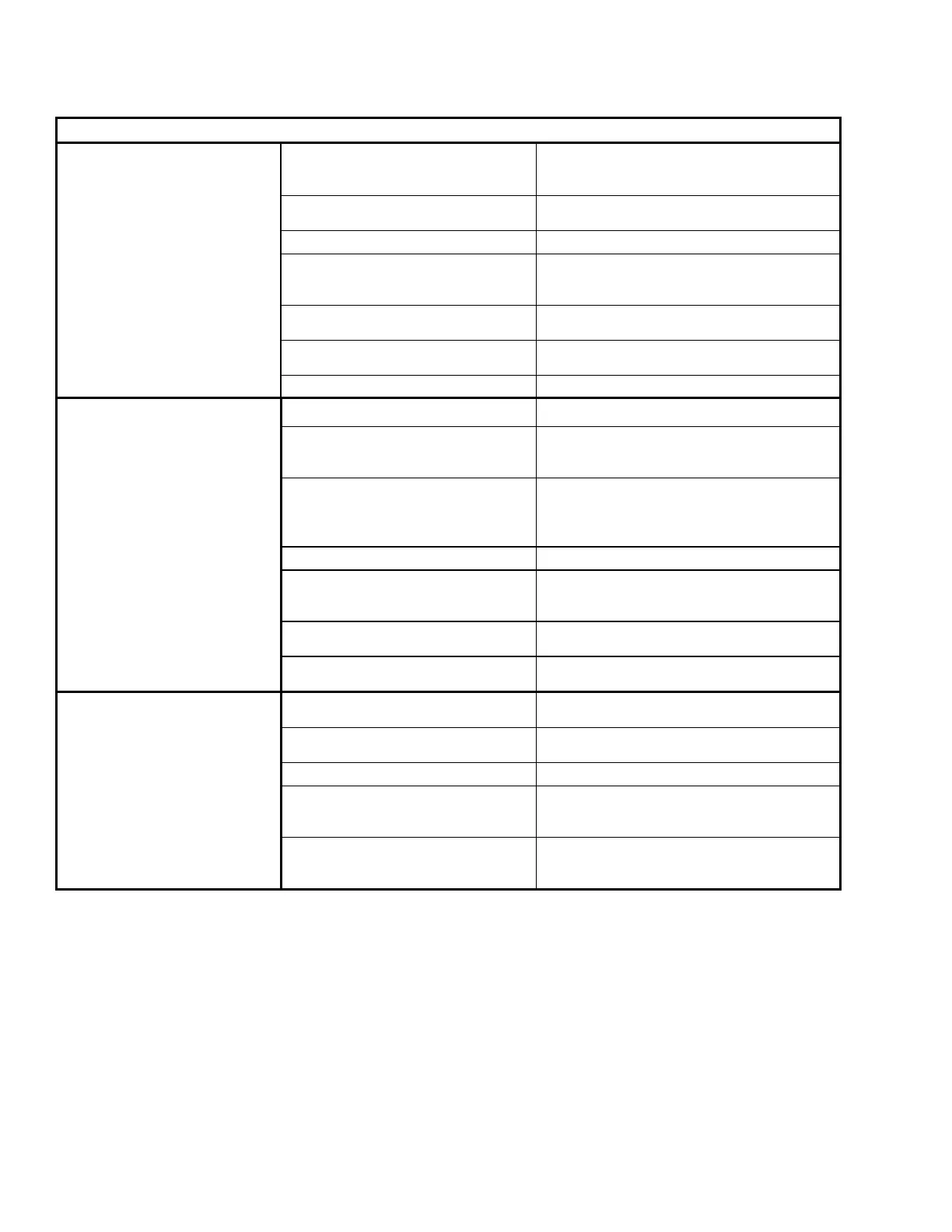

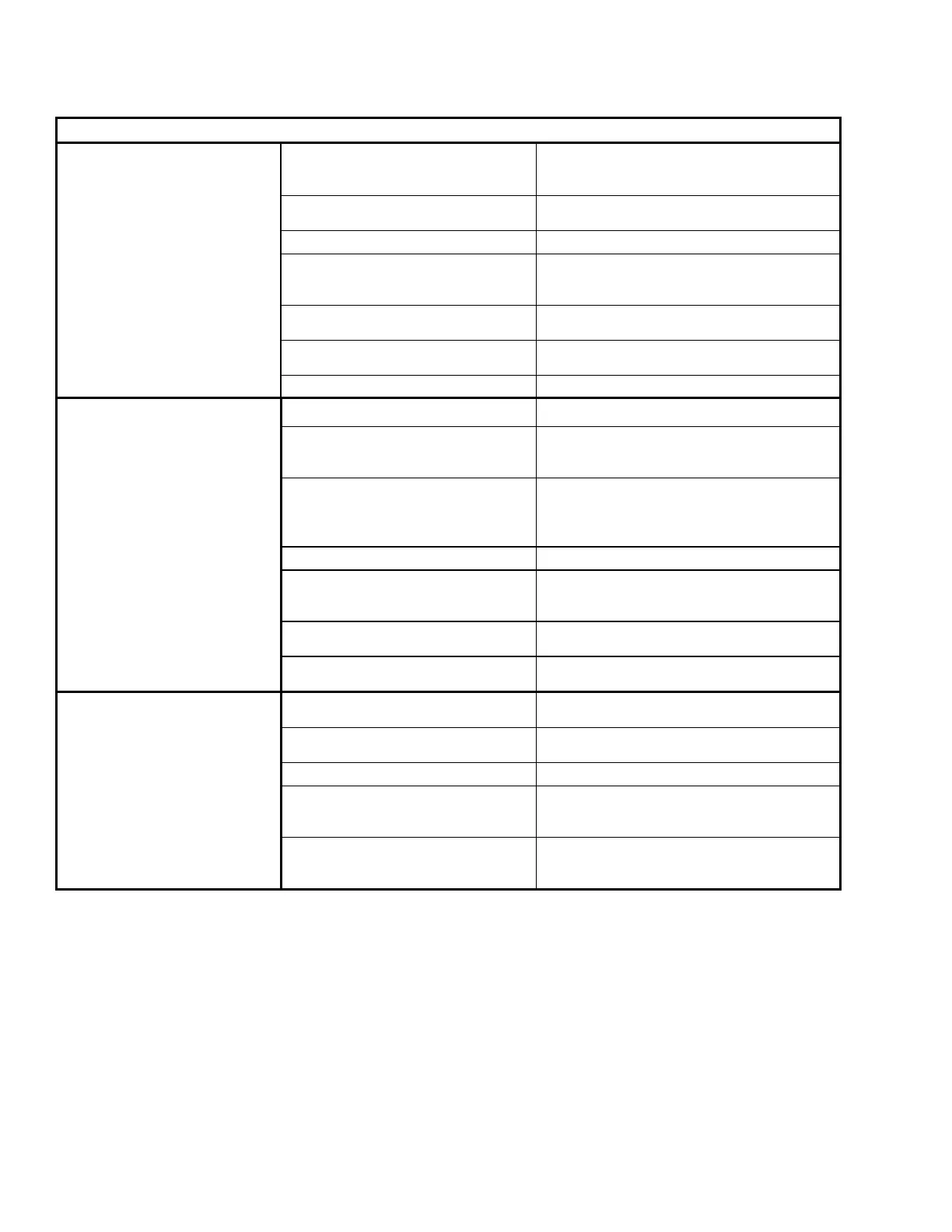

PROBLEM CAUSE SOLUTION

Main circuit breaker on the control

panel has been tripped.

After inspecting the unit to determine the

cause of the tripped circuit breaker, press

the reset button.

Loose or corroded battery.

Clean, tighten, or replace the battery

terminals.

Dead battery. Recharge or replace battery.

Defective ignition switch.

Test ignition switch for power going into the

switch. If there is power going in but NO

power going out, replace the switch.

Defective starter motor.

Test the starter motor. If necessary

replace.

Engine problem.

Refer to the Briggs & Stratton Vanguard

Service and Repair Instructions.

Engine will not start

The engine does not turn over

Vacuum pump seized (rusty). Refer to Sutorbilt Service & Repair Manual.

Waste tank is full Empty waste tank.

Main circuit breaker on the control

panel has been tripped.

After inspecting the unit ot determine the

cause of the tripped circuit breaker, press

the rest button.

Engine coolant temperture has

exceeded 275°F, triggering the high

temperature switch to shut the unit

down.

Determine the cause of the overheating

before restarting the unit. See “Excessive

Heating” in the Troubleshooting section of

this manual.

Defective fuel pump Replace fuel pump.

Defective float switch inside the

waste tank.

Disconnect the float switch plugs and

bypass the float switch. If the unit starts,

repair or replace the defective float switch.

Defective 275°F engine coolant

high-temperature shutdown switch.

Test switch. If necessary, replace.

Engine stops running

While doing normal cleaning,

the engine stops running

No ignition in the engine or engine

is malfunctioning.

Refer to the Nissan Engine Operation and

Maintenance Manual.

Strainer or orifice is bypass manifold

is closed position.

Clean strainer screen and orifice. replace,

if needed.

Plugged outlet Y-strainer filter

Remove and clean strainer. Replace, if

necessary.

Jets too small in extracton tool. Install proper size tips or clean, if clogged.

Quick-connect couplers are worn

out or damaged and are not

allowing water to pass readily.

Inspect couplers and replace, if necessary.

Excessive heating

Flow restriction caused by hard

water scaling.

Descale unit, repair or replace damaged

plumbing components as necessary.

Install water softener.

Loading...

Loading...