MAINTENANCE

BLAZER 980073 09/16/02

4-18

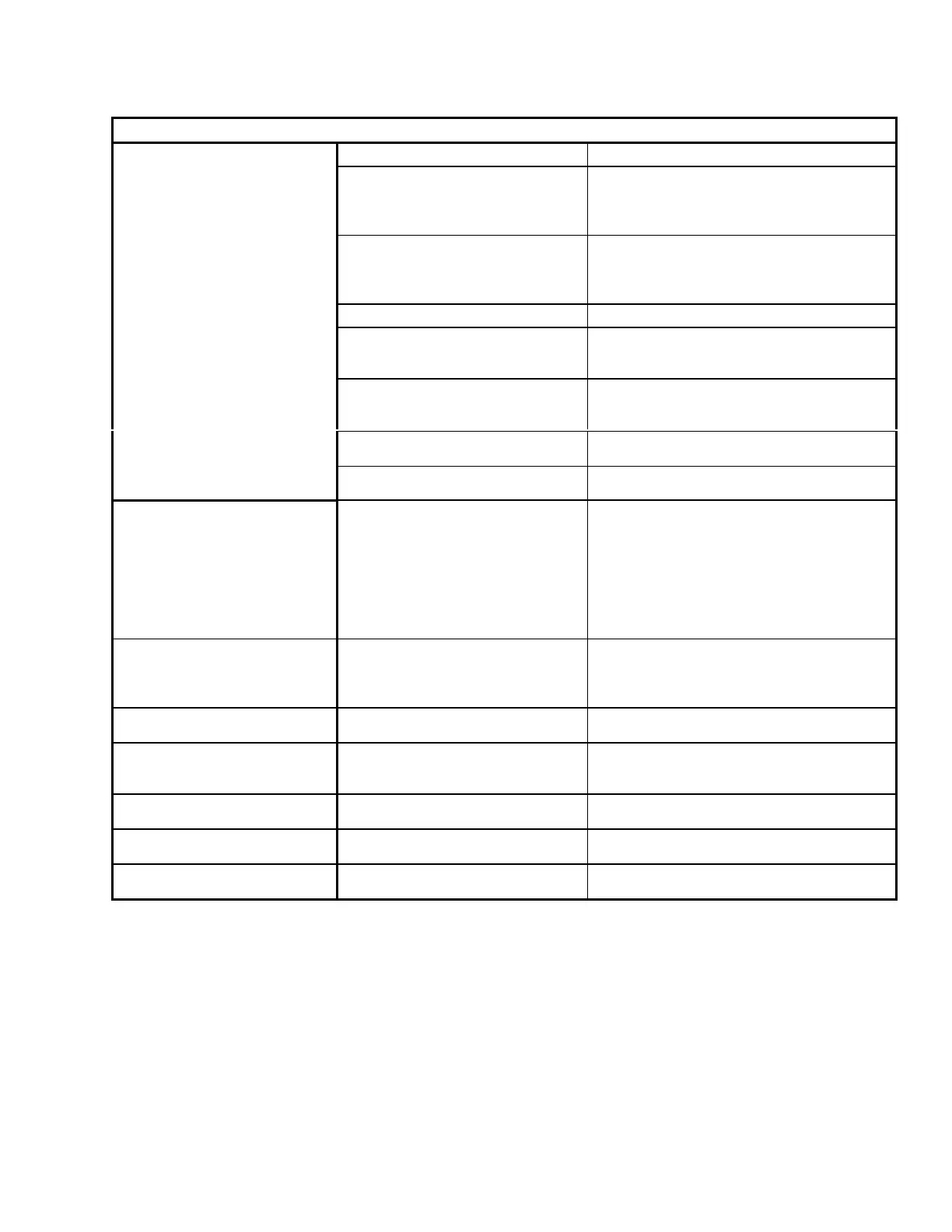

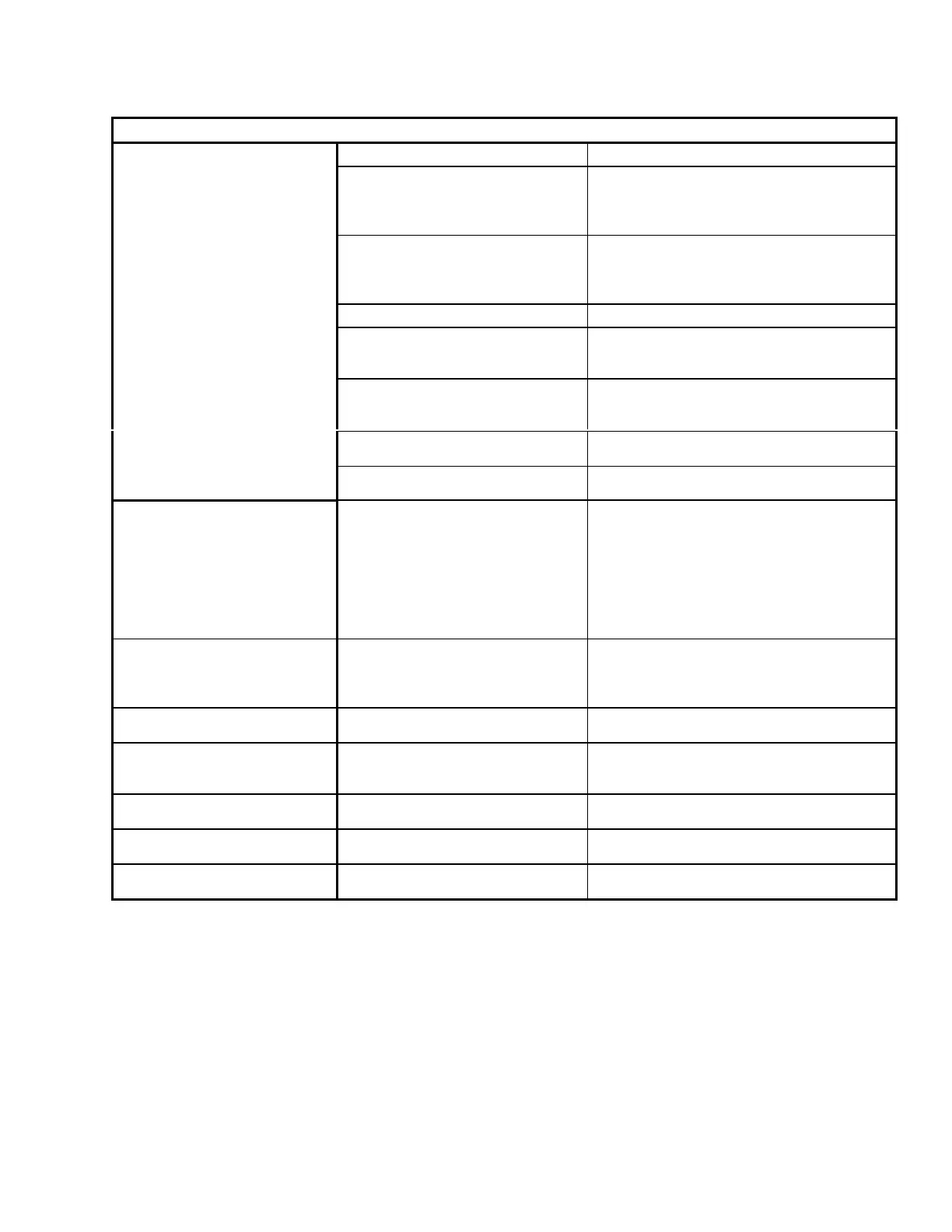

PROBLEM CAUSE SOLUTION

Waste tank is full. Empty the waste tank.

Water pressure has not reached

50 PSI.

Turn water pump switch to the override

position. If the unit shuts back down, refer

to the “Loss of Water Pump Pressure” in the

“Troubleshooting” section of this manual.

Engine temperature has exceeded

275°F, triggering the high

temperature switch to shut the unit

down.

Determine the cause of overheating before

restarting the unit. See “Excessive Heating”

in the “Troubleshooting” section of this

manual.

Defective fuel pump. Replace the fuel pump.

Defective upper float switch in the

waste tank.

Disconnect the float switch plugs and

bypass the switch. If the unit starts, repair

or replace the defective float switch.

Fuel shut-off solenoid, (located on

engine) not operating properly.

Test, and replace if defective. Refer to the

Briggs & Stratton Vanguard Service and

Repair Instrictions.

Defective 275° engine high-

temperature shutdown switch.

Test switch. If necessary, replace.

Starter turns over engine, but

will not start

Engine is malfunctioning

Refer to the Briggs & Stratton Vanguard

Service and Repair Instrictions.

Heat exchanger leaks

NOTE: The engine exhaust

heat exchanger will produce

water condensation discharge

at times during normal

operation. DO NOT confuse

this with a leak.

Engine and vacuum exhaust heat

exchanger are damaged from

frozen water

Inspect heat exchanger for leaks. On pre-

heaters visually inspect for damage.

Pressure check both styles after removing

them from the unit. (Maximum test pressure

engine exhaust H.E. 1200 PSI vacuum pre-

heaters 300 PSI).

Loss of temperature

The heat output of the unit is

LESS than normal.

Temperature relief valve on water

box is defective, or stuck.

Clean temperature relief valve and test.

Replace, if necessary.

Engine RPM is low.

Clean temperature relief valve and test.

Replace, if necessary.

Engine exhaust heat exchanger is

carbon-coated on outside of coil.

Soak coil section at a radiator shop. Boil

tank or soak in PROCHEM Industrial

cleaner.

Damaged or plugged radiator core

in vacuum exhaust heat exchanger.

Remove and inspect cores. Replace, if

necessary.

Engine exhaust heat exchanger is

scaled on outside of coil.

De-scale coil. Install water softener if

needed.

Worn bypass manifold, worn or

improperly installed bypass orifice.

Inspect bypass manifold. Repair as

needed.

Loading...

Loading...