- 16 -

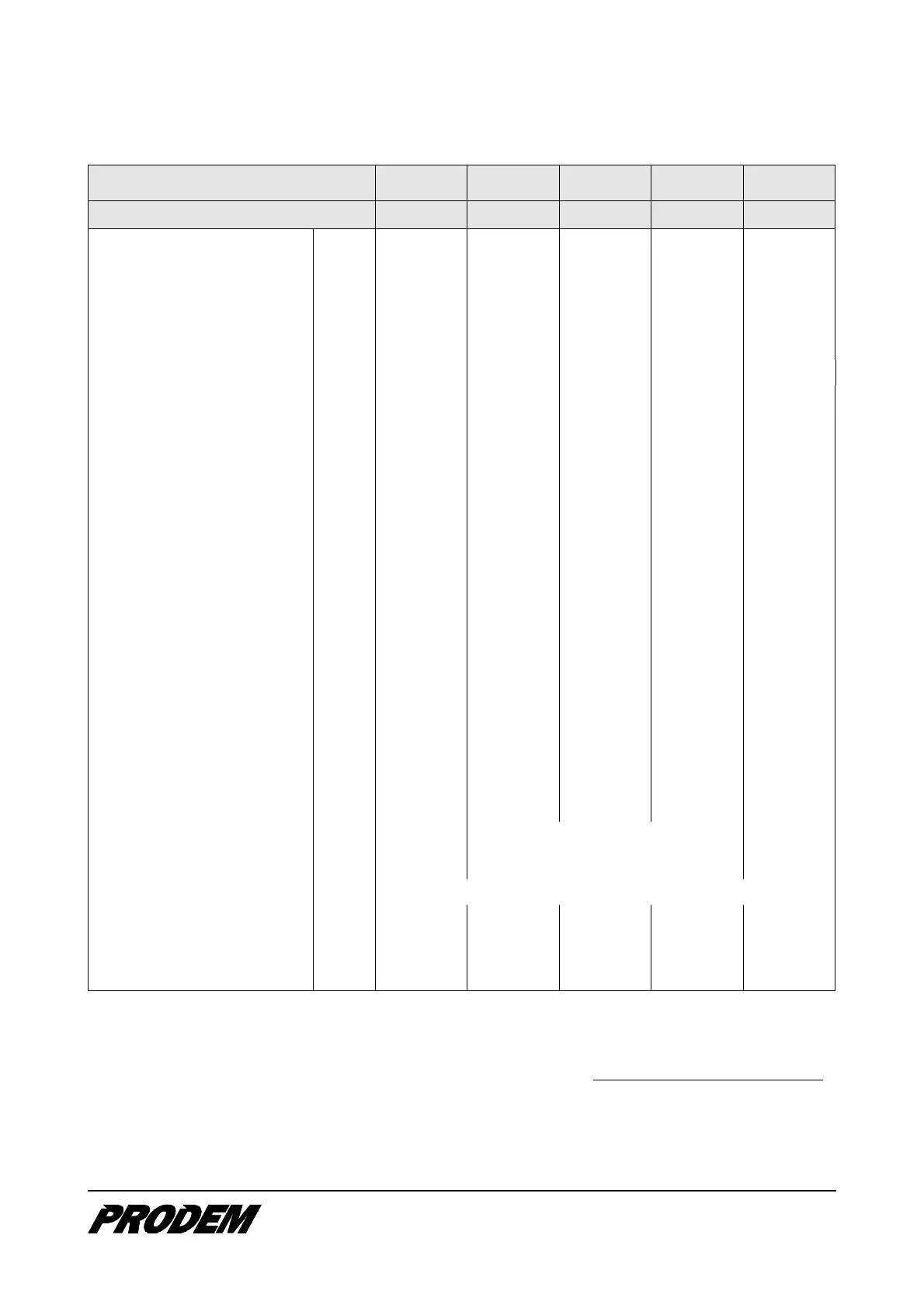

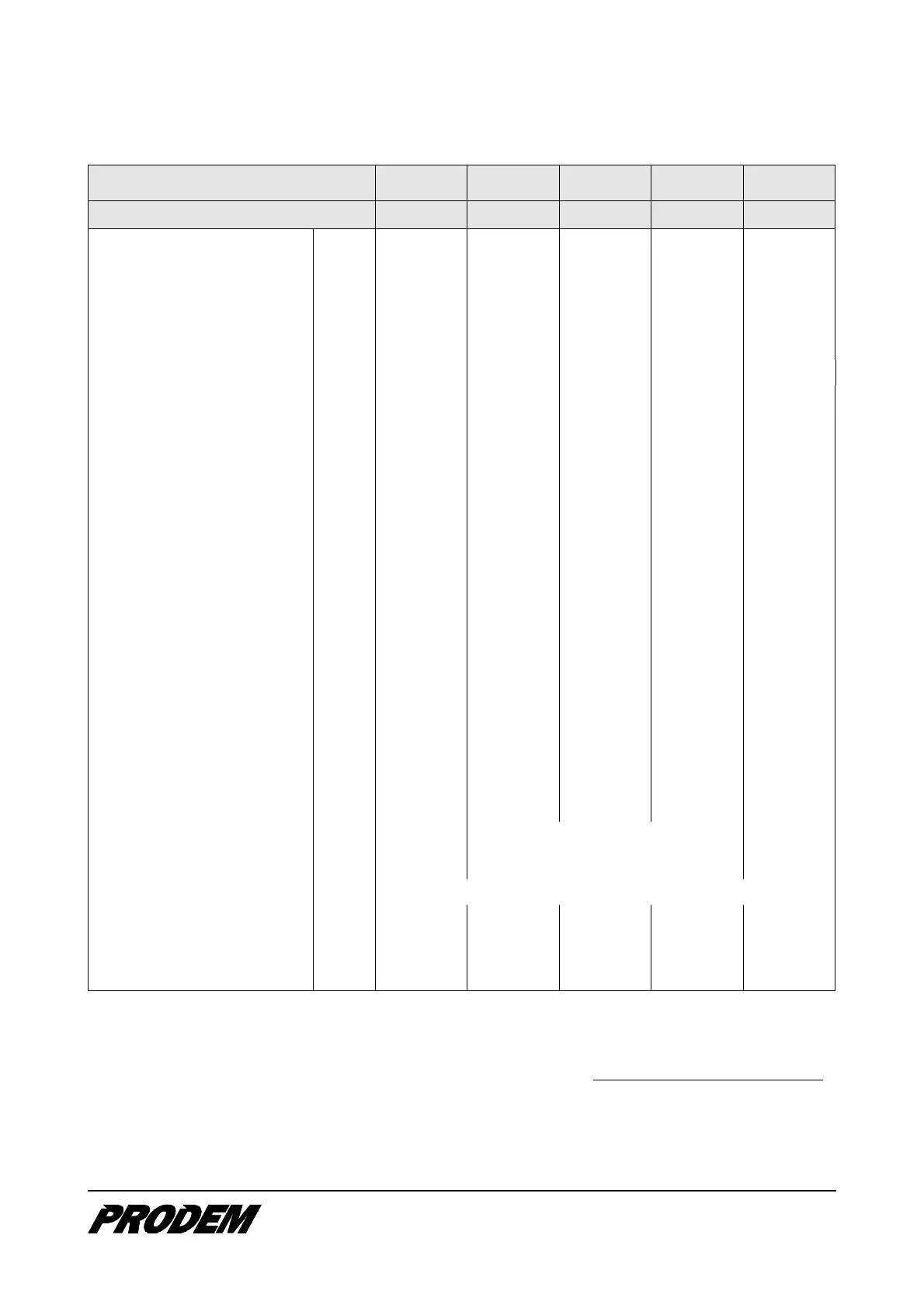

PRB050 / 060 / 100 / 150 / 170

Model

PRB050 PRB060 PRB100 PRB150 PRB170

Bracket version

1)

NA

BA

NA

BA

NA

BA

BA BA

Working weight

2)

kg 330

314

455

468

549

552

1,040 1,341

Weight w/o mounting adapter kg 284

268

385

398

479

482

892 1,121

Overall length

3)

mm 1,674

1,682

1,916

1,933

2,049

2,066

2,375 2,642

Required oil flow rate l/min 35 ~ 65 45 ~ 90 60 ~ 110 80 ~ 140 110 ~ 170

Operating pressure bar 130 ~ 170 130 ~ 170 140 ~ 180 140 ~ 180 160 ~ 180

Input power (max.) kW 18.4 25.5 42 51

Impact rate

Low speed mode bpm n/a n/a n/a 380 ~ 700 350 ~ 600

High speed mode bpm 550 ~ 1,000

520 ~ 1,000

500 ~ 1,000

550 ~ 850 500 ~ 750

Impact Energy

4)

Low speed mode Joule n/a n/a n/a 2,500 2,800

High speed mode Joule 700 1,000 1,350 2,150 2,200

Tool shank diameter mm 68 80 105 117

Applicable carrier weight

Optimal range tonne

4.0 ~ 6.0 6.0 ~ 8.0 8.0 ~ 12 12 ~ 16 18 ~ 22

Available range tonne

3.5 ~ 8.0 5.0 ~ 11 7.0 ~ 15 12 ~ 20 14 ~ 24

Gas charging pressure

Back-head bar 15~17 15 ~ 17 15 ~ 17 15 ~ 17 15 ~ 17

Accumulator bar n/a n/a n/a n/a 60

Pressure adjust valve setting

(No. of turns open from full-close)

n/a n/a n/a n/a 1.5~2.0

Hydraulic piping

Line size; min. internal diameter

mm (in)

12 (1/2) 19 (3/4) 19 (3/4) 19 (3/4) 25 (1)

Acceptable back pressure

5)

bar 15 15 15 15 10

Hose connection ports for

Oil supply(IN) & return(OUT)

BSP 1/2”

O-Ring boss

female

BSP 3/4”

O-Ring boss female

BSP 1”

O-Ring boss

female

Pressure relief (min.) bar 40 bar higher than measured maximum operating pressure

Acceptable Hydraulic oil

-20 ~ +85

Operating temperature °C 1,000 ~ 10

-20 ~ +85 -20 ~ +85 -20 ~ +85 -20 ~ +85

Viscosity cSt

35 ~ 65

1,000 ~ 10

1,000 ~ 10

1,000 ~ 10

1,000 ~ 10

Note:

1) For the specifications of other versions of bracket, contact your PRODEM dealer or service.

2) Including standard tool, standard mounting adapter and spacers but excluding hydraulic hoses, fittings and

mounting pins.

3) Measured from the tool tip of the standard tool to the top of the breaker excluding standard mounting adapter.

4) Measured in accordance with the certified test procedure which complies with the AEM Tool Energy Rating for

hydraulic breakers.

5) The maximum allowed oil pressure at the breaker's connection point to the return line (measured statically

without the breaker)

Loading...

Loading...