- 15 -

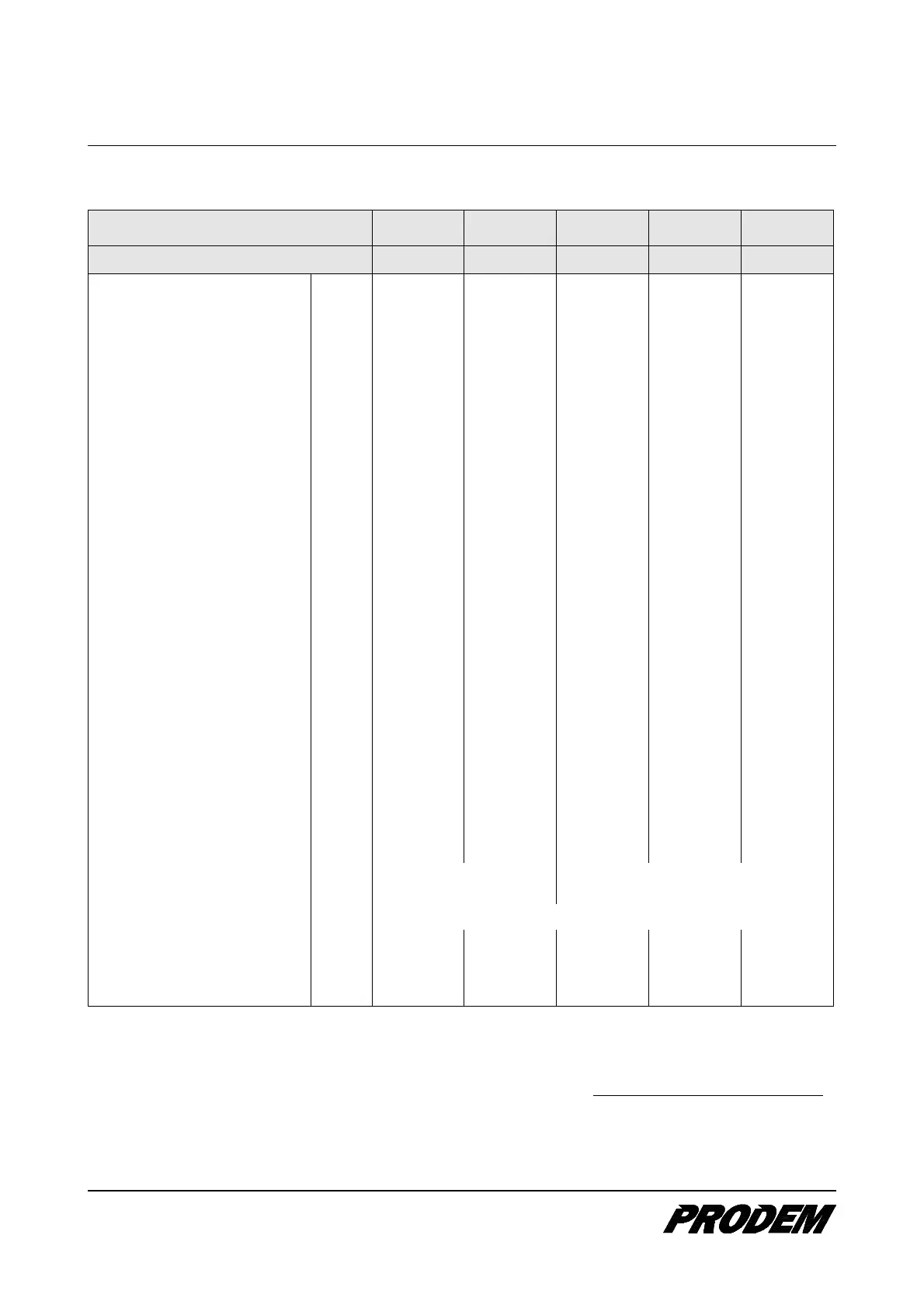

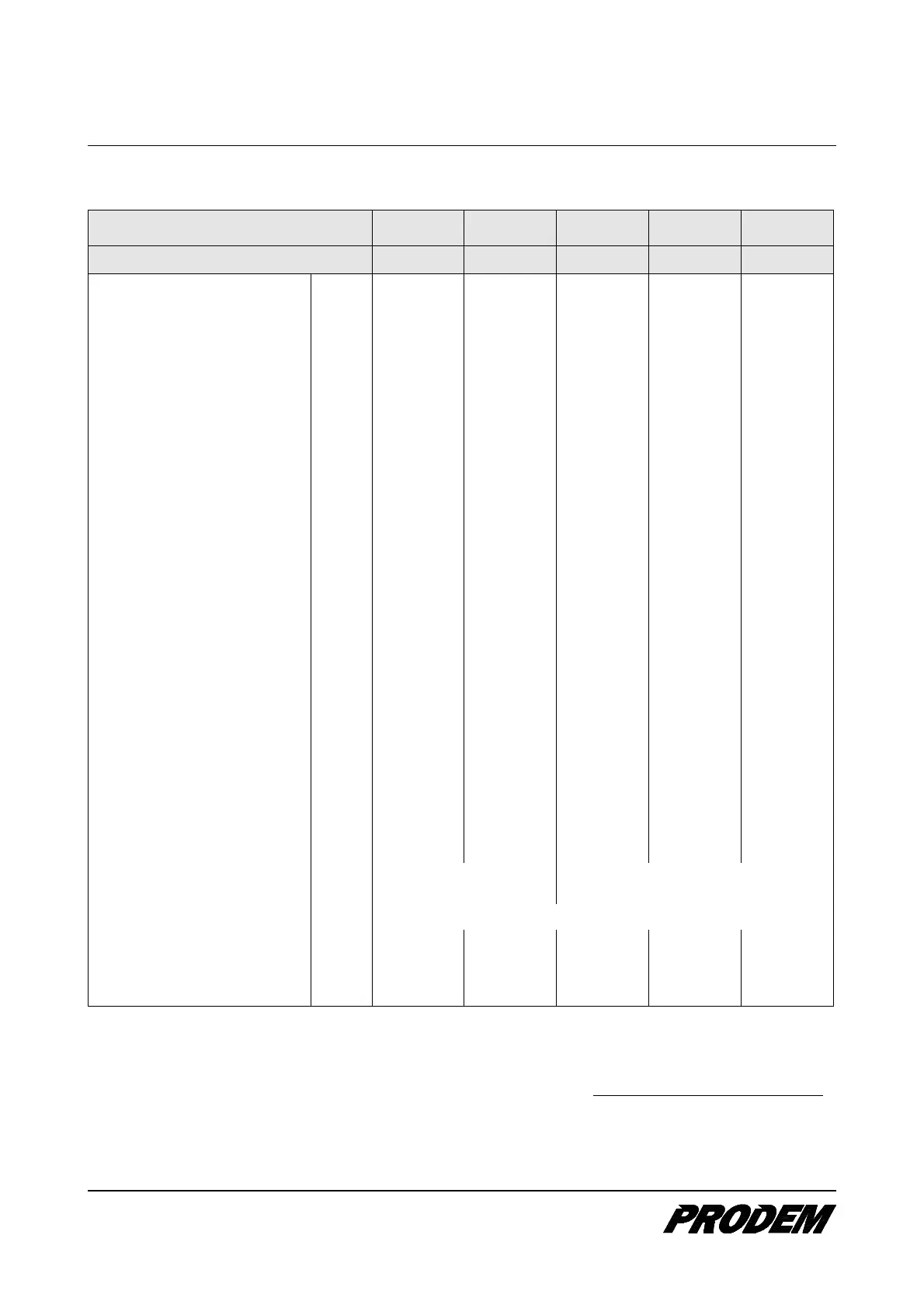

4. Technical specifications

PRB008 / 010 / 020 / 030 / 040(H)

Model

PRB008 PRB010 PRB020 PRB030 PRB040(H)

Bracket version

1)

NA

BA

NA

BA

NA

BA

NA

BA

NA

BA

Working weight

2)

kg 79 80 116

116

116

116

142

144

211

243

Weight w/o mounting adapter kg 69 70 98 98 98 98 124

126

181

213

Overall length

3)

mm 1,070

1,065

1,207

1,215

1,207

1,215

1,242

1,257

1,390

1403

Required oil flow rate l/min 15 ~ 30 15 ~ 25 20 ~ 35 20 ~ 35

30 ~ 50 /

50~75(H)

Operating pressure bar 100 ~ 130 100 ~ 130 100 ~ 130 100 ~ 130 110 ~ 140

Input power (max.) kW 6.5 5.4 7.6 7.6 11.7 / 17.5(H)

Impact rate

Low speed mode bpm n/a n/a n/a n/a n/a

High speed mode bpm 550 ~ 1,300

700 ~ 1,200

700 ~ 1,200

550 ~ 1,000

550 ~ 1,000

Impact Energy

4)

Low speed mode Joule

n/a n/a n/a n/a n/a

High speed mode Joule

110 180 200 300 450

Tool shank diameter mm 42 45 45 50 58

Applicable carrier weight

Optimal range tonne

0.7 ~ 1.0 0.7 ~ 1.2 1.0 ~ 2.5 1.5 ~ 3.0

2.5~4.5/4.0~6.0(

H)

Available range tonne

0.6 ~ 1.5 0.7 ~ 2.5 1.0 ~ 4.0 1.5 ~ 4.5

2.5~6.0/2.5~8.0

H)

Gas charging pressure

Back-head bar 8~10 8~10 8~10 8~10 10~12

Accumulator bar n/a n/a n/a n/a n/a

Hydraulic piping

Line size; min. internal diameter

mm (in)

9.5 (3/8) 9.5 (3/8) 12 (1/2) 12 (1/2) 12 (1/2)

Acceptable back pressure

5)

bar 15 15 15 15 15

Hose connection ports for

Oil supply(IN) & return(OUT)

BSP 3/8”

O-Ring boss female

BSP 1/2”

O-Ring boss female

Pressure relief (min.) bar 30 bar higher than measured maximum operating pressure

Acceptable Hydraulic oil

Operating temperature °C -20 ~ +80 -20 ~ +80 -20 ~ +80 -20 ~ +80 -20 ~ +80

Viscosity cSt 1,000 ~ 12

1,000 ~ 12

1,000 ~ 12

1,000 ~ 12

1,000 ~ 12

Note:

1) For the specifications of other versions of bracket, contact your PRODEM dealer or service.

2) Including standard tool, standard mounting adapter and spacers but excluding hydraulic hoses, fittings and

mounting pins.

3) Measured from the tool tip of the standard tool to the top of the breaker excluding standard mounting adapter.

4) Measured in accordance with the certified test procedure which comply with the AEM Tool Energy Rating for

hydraulic breakers.

5) The maximum allowed oil pressure at the breaker's connection point to the return line (measured statically

without the breaker)

Loading...

Loading...