- 34 -

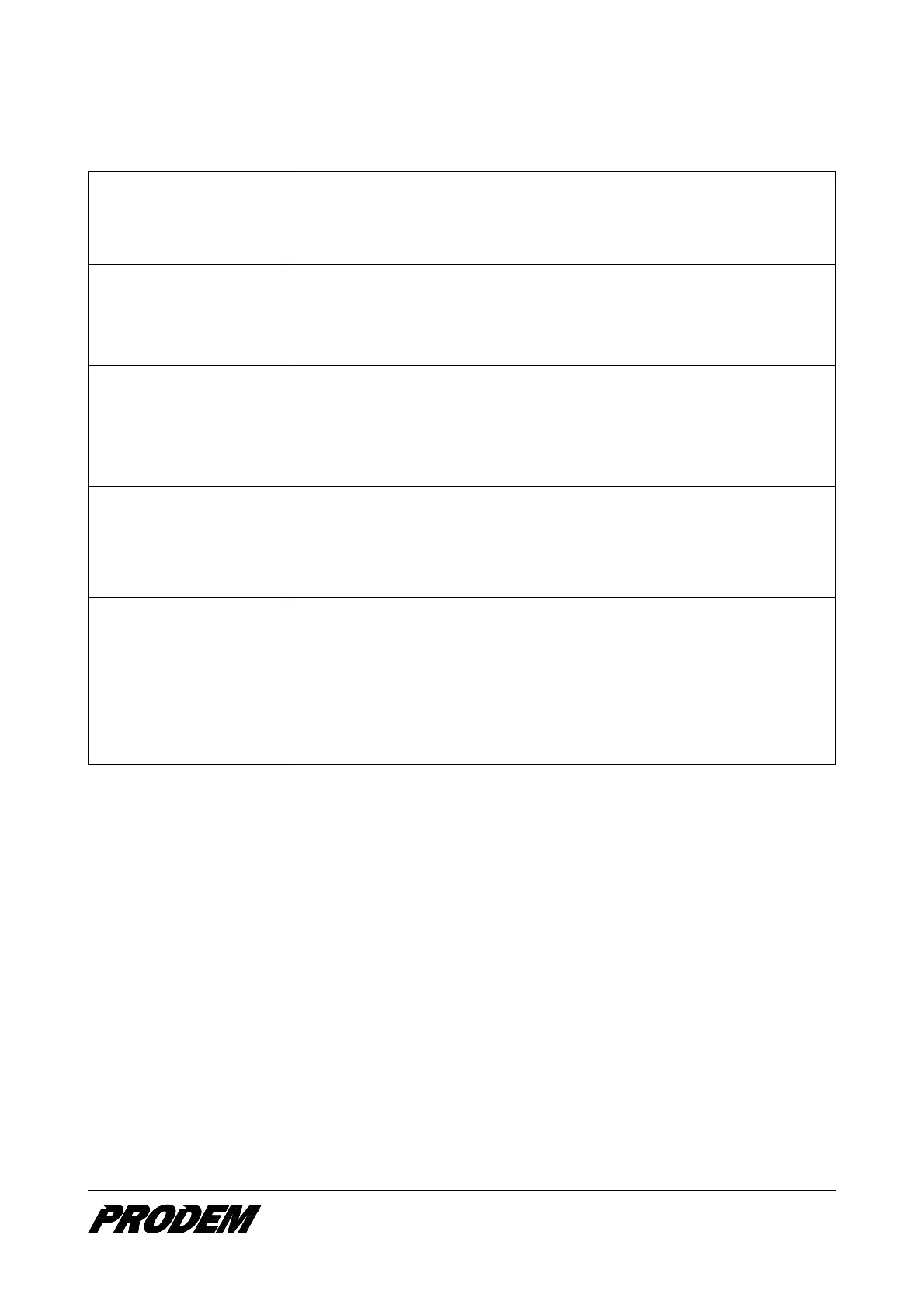

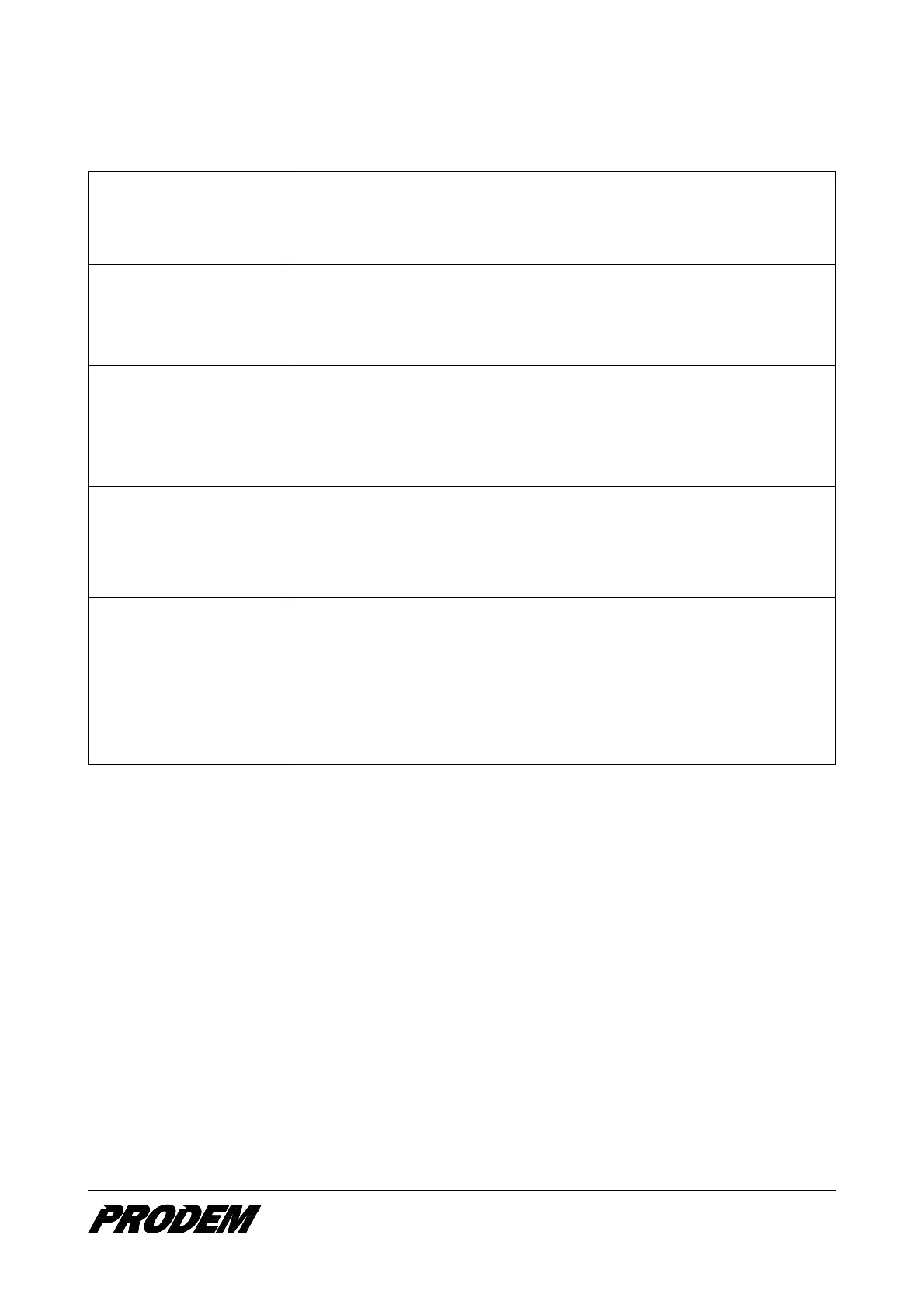

7.2. Care and maintenance schedule

To keep the hammer condition at its best, maintenance must be done regularly to the schedule below.

Every 2 hours

Grease the chisel and chisel bush.

Check hydraulic oil temperature, piping & connection and impact efficiency.

Tighten loose connections.

Every 10 hours or daily

Remove the retaining pin and the chisel and check their condition. Grind

off any burrs that may be present.

Check that the chisel has been receiving sufficient grease.

Grease more frequently, if you needed.

Every 50 hours or weekly

(Main inspection)

Check gas pressure in the back-head. Refill the gas if necessary.

Check for wear of the chisel, front bush, chisel bush and piston lower part.

Check the hydraulic hoses, Replace if necessary

Check through bolts, Replace and/or re-tighten if necessary.

Every 100 hours or

monthly

It is recommended to have the main inspection done by your local PRODEM

dealer.

Check all hydraulic hoses and pipe connections.

Check interference between hoses with carrier.

Every 600 hours or

6 monthly

It is recommended that the annual maintenance be carried out by your local

PRODEM dealer, or after 600 operating hours.

Check all hydraulic pipe, hose connections and conditions of oil filters

Check through bolts for cracks on the threads and shanks.

Change all seals including the accumulator diaphragm.

Check the conditions of the power cell and bracket.

7.3. Hydraulic oil

Most of the hydraulic oil brands prescribed by the carrier manufacturer are suitable for the PRODEM

hydraulic hammer. However, operating the hydraulic hammer will heat up the oil much more than the usual

earth moving work.

Therefore, the hydraulic oil should correspond to viscosity class HLP32 or higher; in general case viscosity

class HLP46 is recommended. In summer and in hotter climates, oils of viscosity class HLP 68 or higher

should be used.

Optimum viscosity range: 20 ~ 60 cSt

Maximum initial viscosity: 1,000 cSt

Minimum viscosity: 12 cSt for PRB008 ~ 040

10 cSt for PRB050 ~ 700

Maximum oil temperature (with HLP46 oil):

80°C (176°F) for PRB008 ~ 040

85°C (185°F) for PRB050 ~ 700

Loading...

Loading...